Transformer explosion and fire prevention

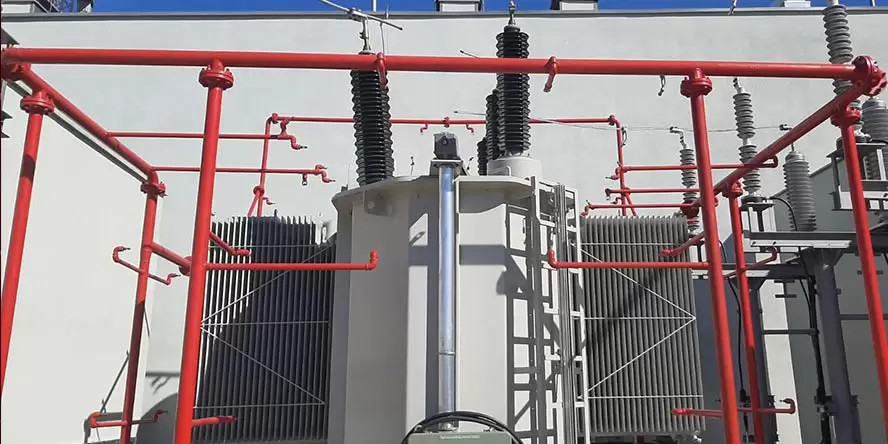

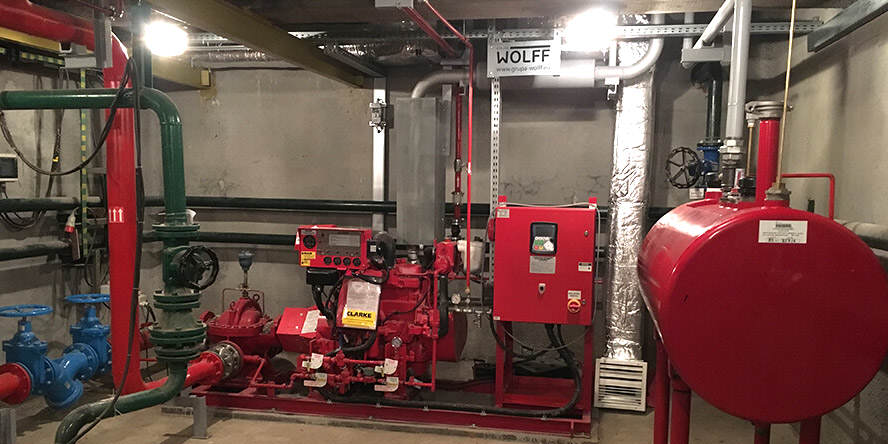

We design, supply and install oil-filled transformers fire fighting systems for transformers used in the power, district heating and distribution networks of large industrial plants. Each transformer, located outside the building, is surrounded by a transformer explosion and fire prevention installation in the form of a cage, on which sprinklers are located. We design their number and positioning to ensure that the burning transformer is sprayed evenly with water. The result is both the extinguishing of the transformer fire and the cooling of the components not yet involved in the fire. The latter function provides protection against the fire spreading to other parts of the installation or the building and gives time for the arrival of the fire brigade.

How do we protect transformers?

Fire extinguisher for transformers is based on two pillars: the transformer fire suppression system and the fire detection and extinguishing control system.

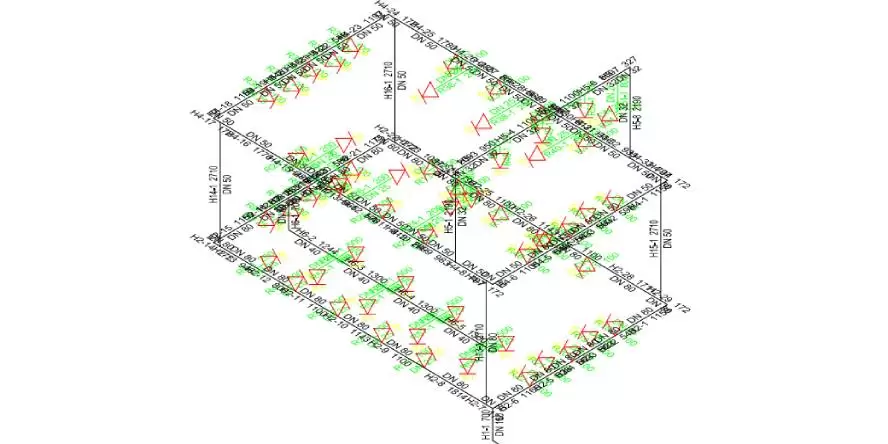

CAGE WITH DELUGE SPRINKLERS

A self-supporting cage

No need for an additional support structure

Bolted flange joints give the cage the required rigidity

Prefabricated cage components

Double-sided hot-dip galvanised tubes

Special anti-corrosion layers

Hydraulic calculation for uniform sprinkler distribution

DETECTION AND CONTROL

Diaphragm deluge valves

Hydraulic and electrical connections to existing systems

Temperature rise monitored by sensor cable

This detector requires no maintenance and no special protection

Connection of the transformer to the Buchholz relay

Optical / acoustic alarm and signal transmitted to control room

Manual or automatic activation of extinguishing

Fire safety standards, norms and guidelines in our projects

We design, carry out installation work and commissioning in accordance with the standards required by the owner. We are aware that specific guidelines are often imposed by the insurance companies, so we cannot afford even the smallest mistake that would result in the risk of non-payment of compensation.

Also, all delivered and used components of the fire protection system for transformers always have the certificates and approvals required by the owner and their insurance company.

CNBOP

All the components used by us have the required CNBOP approvals

VdS

The German VdS guidelines are one of the two most widely used fire safety guidelines in the world.

FM Global

The US insurer’s guidelines are the second most widely used fire protection standards in the world.

NFPA 15 (Standard for Water Spray Fixed Systems for Fire Protection)

NFPA 850 (Recommended Practice for Fire Protection for Electric Generating Plants and High Voltage Direct Current Converter Stations)

Standard PN-M-51541 “Fire protection. Sprinkler equipment”

Standard PN-B-10725:1997 “Water supply systems. External piping. Requirements and testing”.

Completed transformer fire protection projects

Power Plant

Company from the fertilizer and chemical industry

Chemical conglomerate

Transformer fires

Transformer fires are a fairly common occurrence in industry. Usually the root cause is an electrical short circuit. When this occurs, the temperature in the transformer installation rises sharply. Often, there is also an explosion in the ladle, which leads to the lid unsealing and oil ejection. As a result, the oil, which in normal operation acts as a cooling medium for the transformer, becomes a combustible fuel.

Fire at the Rybnik Power Plant

- March 2014,

- damage to the transformer isolation conduit,

- massive short-circuit,

- explosion in a transformer vat,

- the lid of the vat opened,

- the ejection and discharge of oil that has ignited.

Fire at a Chemical and Cosmetics Manufacturer

- June 2022,

- the direct cause was a lightning strike,

- the estimated losses were 200,000 PLN

Transformer

station fire

- November 2011,

- several transformers were involved in the fire,

- in total, more than 50 tonnes of oil caught fire.

Electrical

substation fire

- June 2019,

- one of the insulators of the 400/110 kV power transformer on the 400 kV side was punctured,

- a fire broke out which, thanks to the rapid response of the deluge sprinkler system, was brought under control

- the fire had already been extinguished before the arrival of the fire brigade,

- serious losses were avoided.

Work stages for a fire protection project. Transformers

Site visit for fire protection for transformers

One of the first actions we take when we are approached by the final owner or general contractor of a major project is a site visit. A visit to an energy or industrial site allows us to collect all the data necessary for further design work. During the site visit we will be interested in the following information:

- the location of the transformer (or future location)

- existing fire water supply. (or lack thereof)

- whether other transformers with fire protection are already in operation nearby, so that complementary solutions can be adapted if necessary

- technical and construction documentation

- we will also take the necessary measurements

Design of the installation

When embarking on the design of a sprinkler system for the fire protection of transformers, we meticulously select each component of the system. At this stage, we take into account any measurements taken beforehand or the existing infrastructure on the owner’s site (such as the water supply). If necessary, we also design the required but missing infrastructure. One of the most important parts of the design is the appropriate positioning of the sprinklers, together with determining the intensity of sprinkling over the entire transformer area. The ultimate effectiveness of the installed system depends on this action.

Supply and installation of fire protection systems for transformers

The next step is the supply and installation of the sprinkler system. The self-supporting cages we recommend must be prefabricated in advance. This requires us to be very precise when taking measurements, as there will be no possibility of trimming the components during assembly. A definite advantage of this solution is that there is no need to build an additional support structure.

At this stage, we also often work with software suppliers for the control systems already in place at the site to plug into the fire system of the transformers.

Testing, commissioning and training

Once the fire protection system of the transformers is installed, connected to the electrical system and the fire water supply, we proceed to carry out all the tests required by the standards. Once these have been successfully completed, we commission the installation and hand it over to the owner, and carry out all the necessary training.

Fire systems – the offer

Sprinkler systems.

They are self-contained fire extinguishing systems that detect the moment a fire starts, then send information to the control system and automatically start the process of selective water extinguishing – only where there is a fire.

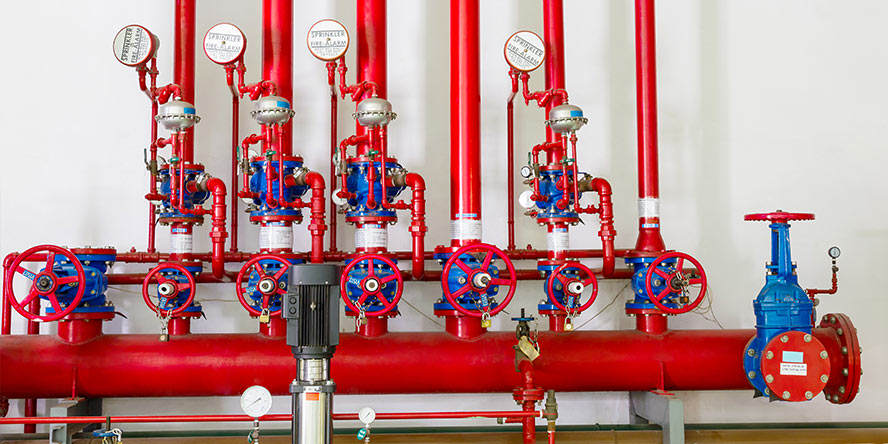

Deluge sprinkler systems.

They are equipped with open fire nozzles and can be divided into several extinguishing zones. When a fire is detected, the sprinkler valves for the area open. Water is released throughout the protected area.

Foam installations.

In particular, we use them for facilities with a high fire risk, such as: tanks for fuels, solvents and other flammable liquids; warehouses for plastics; warehouses for flammable products and/or locations where explosive atmosphere occurs.

Fire Detection and Signalling.

Designing and implementing comprehensive fire detection and alarm systems. Depending on your needs, we use one of the four available systems or a combination of two or three of them, to optimise your investment from a technical and cost perspective.

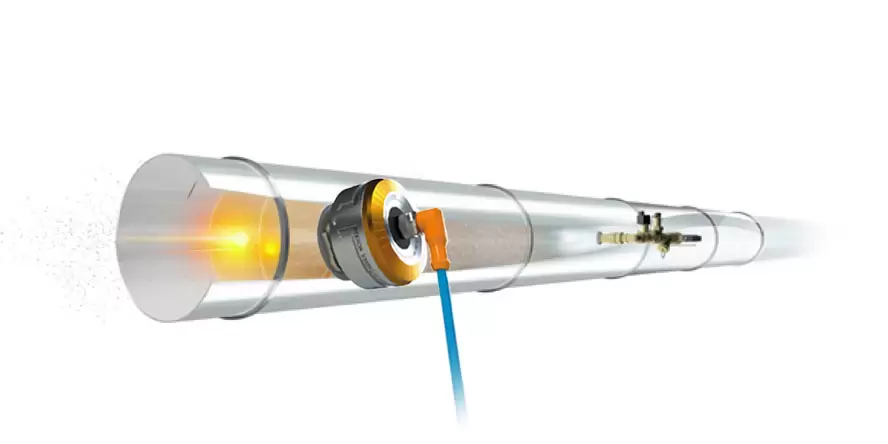

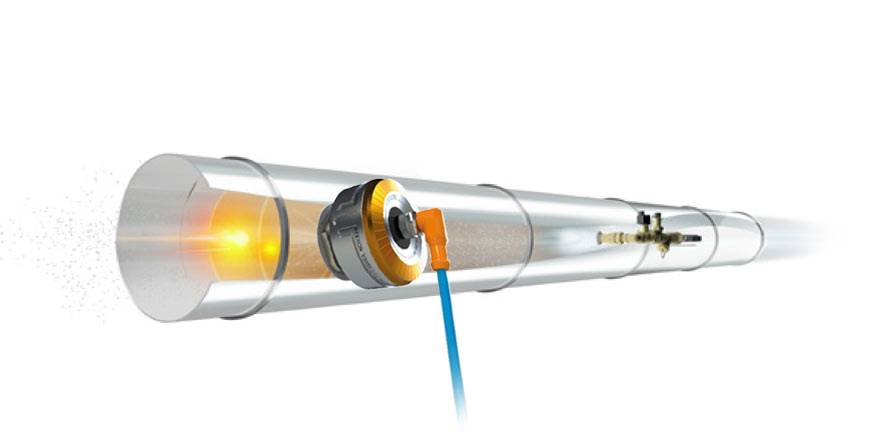

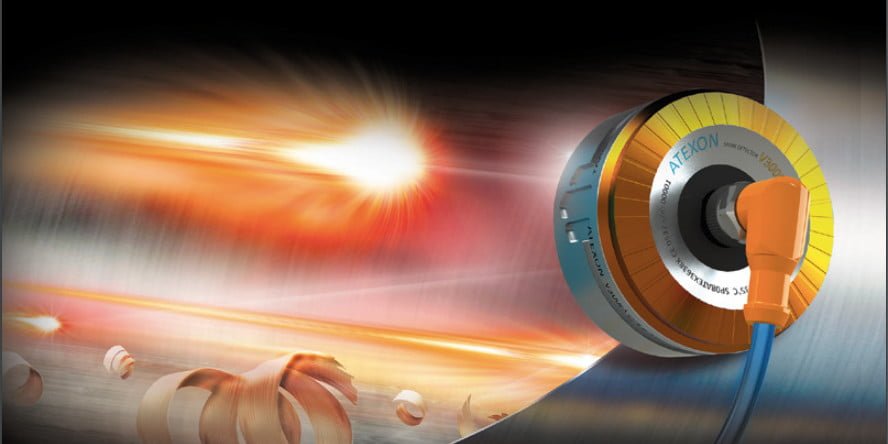

Spark Detection and Extinguishing.

These systems are designed for installation in the ducts of industrial installations. Their purpose is to prevent a potential ignition source in the form of a spark, cigarette butt or heated particle from entering the appliance.

Secure your installation.