Process Systems Inventory Studies

After several years of a process system operation the system technical documents may be incomplete or significantly differ from the actual status. This makes it difficult, or in some cases impossible, to repair, modernise or reconstruct such system. In order to solve that problem, the WOLFF GROUP proposes its customers to carry out an inventory survey for the individual devices and complete industrial systems.

Contact our engineer

We will answer questions about: offer, technical specification, delivery, assembly.

Scope of our activity – industrial structures inventory surveys

Industrial structures inventory surveys – scope of our activity

Which of the following parameters are covered by the inventory survey depends on the survey purpose. For example, in order to determine the equipment resistance to pressure, the sizes of the equipment and actual wall thickness must be measured. On the other hand, in order to find collisions, 3D models must be prepared.

- Equipment size measurement.

- Actual wall thickness measurement.

- Calculation of actual structural strength of equipment and devices.

- Verification of the selection of equipment and security measures with regard to explosion and process safety.

- Preparing 2D drawings and 3D models or a detailed working design.

- Preparing a report and guidelines for improvement of system productivity, efficiency and safety.

How we do it – industrial structures inventory surveys

Depending on the inventory survey purpose, the survey level of detail may differ. For example, the basic survey comprises the measurement of size of the particular system elements (devices, ducts, pipelines, transfer points, etc.) and preparing 2D drawings. On the other hand, the extensive survey may comprise the measurement of the actual wall thickness and calculation of the actual structural strength of the respective pieces of equipment and pipelines. A very interesting solution is to prepare complete working designs and 3D models to highly facilitate and accelerate repair works and reconstruction of systems.

Selected works

- Inventory survey of extraction systems at Nestle Plant in Toruń

- Inventory survey of packing area at Glinojeck Sugar Plant

- Inventory survey of milling plant at Czechnica CHP Station

- Inventory survey of boiler plant at Czechnica CHP Station

- Inventory survey of woodworking shop at Volvo Plant

- Inventory survey of coal milling plant at Górażdże Cement Plant

- Inventory survey of silos at Lambertz Plant

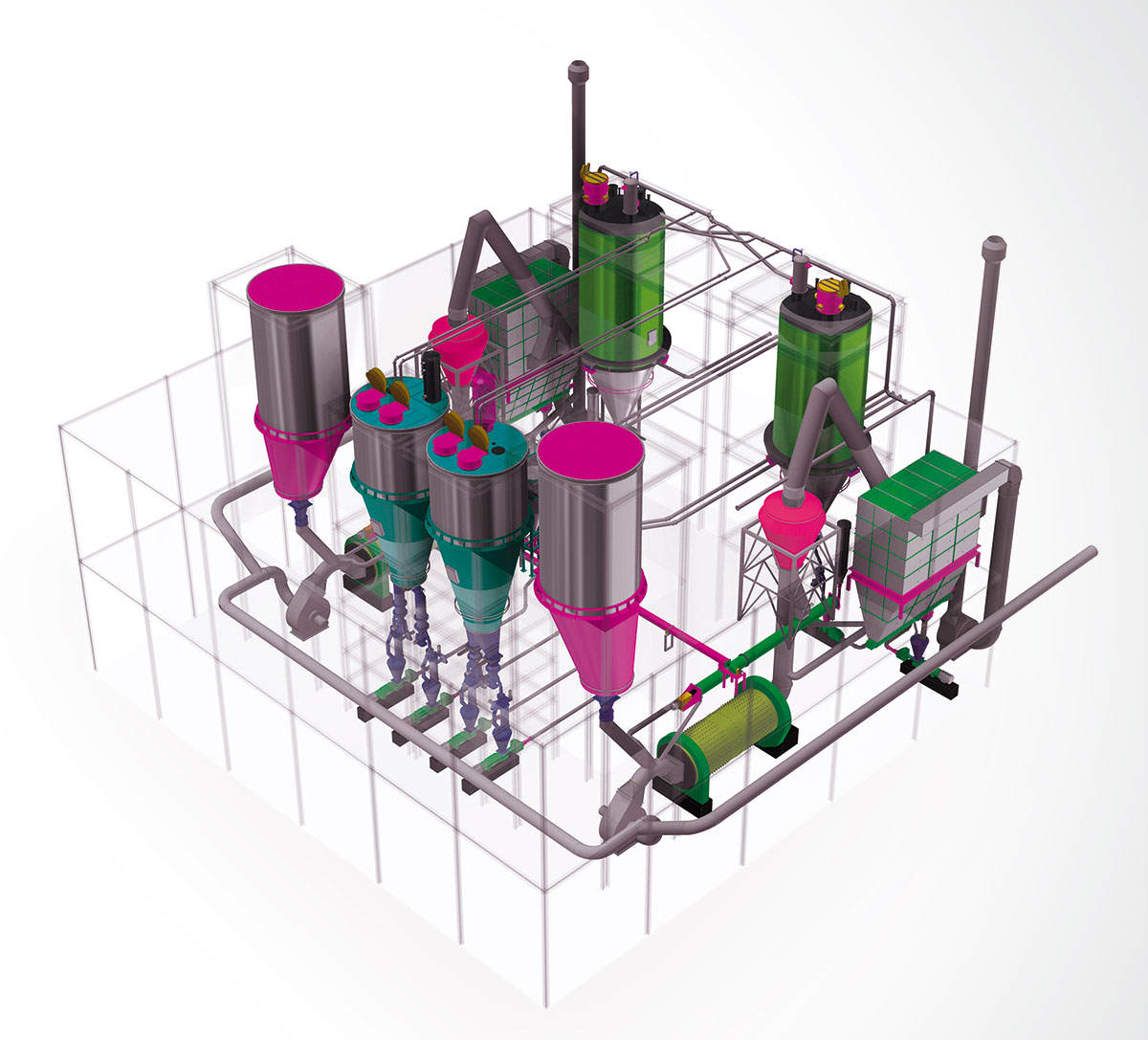

Specimen 3D visualisation created based on an inventory survey

The data collected during an inventory survey were used in preparing a three-dimensional system design and making structural strength calculation of the respective pieces of equipment and devices with the use of Finite Elements Analysis (FEA).

The inventory survey helped to determine which pieces of equipment possess sufficient structural strength for the application of explosion-proof systems. For the pieces of equipment failing to comply with the strength requirement adequate improvements were proposed. 3D models will enable future performance of projects in an efficient manner, without the fear of the existing and new structures collision.