Sludge and Suspensions Dryers / Flakers

GRUPA WOLFF carries out comprehensive deliveries of slurry and suspension dryers and flakers. The machines offered are broadly applied in different industries.

Our engineers’ extensive knowledge and experience allow us to tailor each time the deliveries to our customers’ needs. We implement accompanying investment projects, perform erection, dismantling, replacement, repair and service works, optimise technological processes, and provide engineering consultancy services.

Contact our engineer

We will answer questions about: offer, technical specification, delivery, assembly.

1. DRUM DRYER

The drum dryer consists of a drum, a system dosing product to the drum surface and a scraper. Heating agent flows through the drum interior. A thin layer of product is distributed over the surface of the rotating drum. During an incomplete rotation of the drum, the product is dried and removed from the drum surface by the scraper. The dryer construction prevents any contact of the product with heating agent. The drum dryer is broadly applied for drying viscous products (drying slurries) sensitive to high temperatures or for recovery of solvents and salts from waste streams.

- Drum dryer

- Double-drum dryer for higher capacities

- Drying in an inert gas atmosphere

- Drying in a reduced pressure atmosphere

- In the food industry

- For production of powdered milk, yeasts, starch

- For production of foodstuffs for children and infants

- For production of drinks in powdered form

- In the chemical industry

- For recovery of salt and solvents

- Tests in a laboratory in Holland,

- Design and selection of a proper machine

- Installing, commissioning, service,

- Turnkey project.

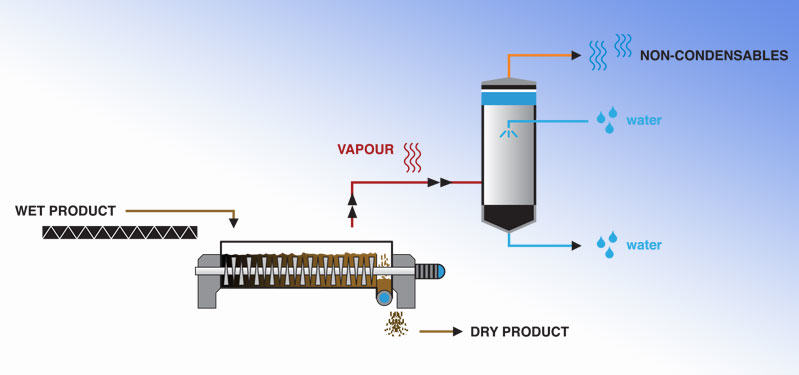

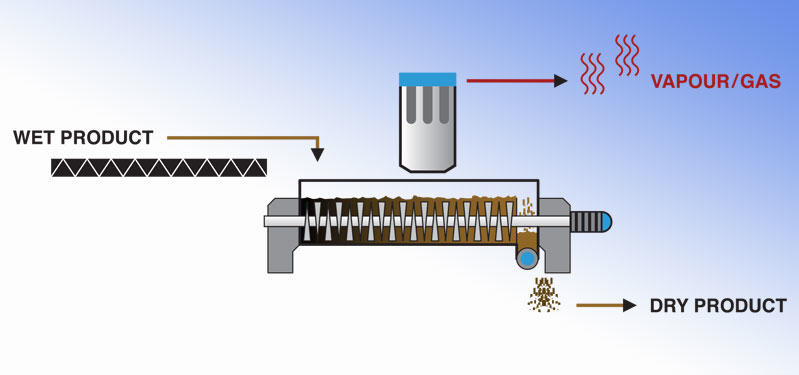

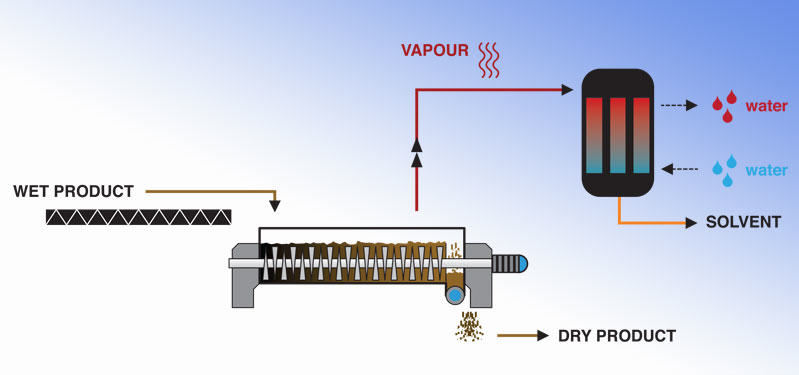

2. PADDLE DRYER

A paddle dryer consists of 2 heated shafts with specially designed paddles and a casing. The paddle is designed so that to that to increase drying efficiency. The design with paddles on the rotating shaft ensures self-cleaning of the paddles. The dryer is inclined at a slight angle to enable a gravitational transport of product.

- Paddle dryer

- In the food industry

- In the chemical industry

- Drying slurries

- Sterilisation

- Tests in a laboratory in Holland,

- Design and selection of a proper machine

- Installing, commissioning, service,

- Turnkey project.

3. FLAKER

The flaker consists of a drum, a system dosing product to the drum surface and a scraper. Cooling agent flows through the drum interior. A thin layer of product is distributed over the surface of the rotating drum. During an incomplete rotation of the drum, the product solidifies and is removed from the drum surface by the scraper. To prevent untimely solidification of the product, the dosing system is heated. The flaker construction prevents any contact of the product with cooling agent. The closed, hermetic construction enables processing of toxic easily oxidising substances, with unpleasant and irritant smell, or hygroscopic substances.

- Flaker

- Solidification process in an inert gas atmosphere

- Heated casing

- In the food industry

- In the chemical industry

- Tests in a laboratory in Holland,

- Design and selection of a proper machine

- Installing, commissioning, service,

- Turnkey project.