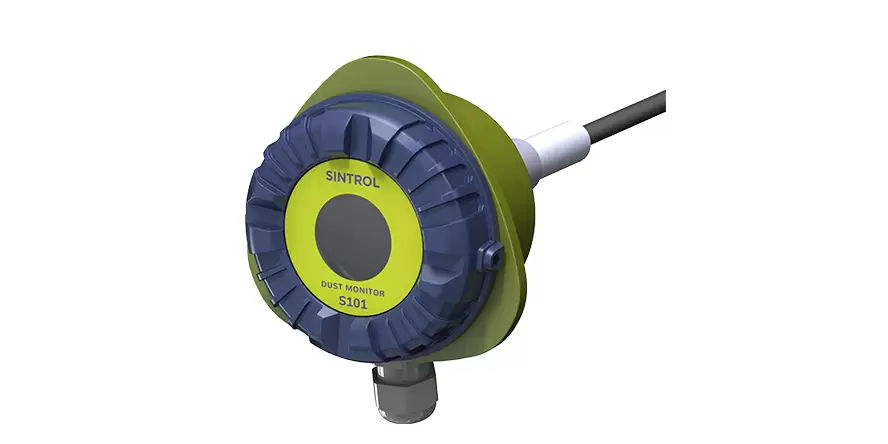

ATEX dust detector

for monitoring of damage to dust extraction units

The ATEX dust meter is designed for use in harsh industrial environments (including explosive atmospheres) to monitor dust levels in ducts and pipelines. It is most often installed on the clean side of the filters and is used to monitor the correct functioning of the dust extraction units. This allows damage to the filter bags to be detected immediately.

The probe is placed directly at the measuring point, and the automatic set-up of the dust meter takes a maximum of eight minutes, making the device virtually maintenance-free and low-cost to operate afterwards.

Key features

Instant calibration

You only need about 8 minutes to have each of the dust meters ready to go, all thanks to automatic configuration and calibration.

Robust design

Robust aluminium die-cast housing with IP65 protection

A proven method of measurement

The reliable method based on inductive electrification provides an extremely wide measurement range with a detection limit of 0.01 mg/m³

Maintenance Department Optimisation

With the software, you can manage the sensors and analyse dust trends, thus optimising the frequency of dedusting equipment maintenance.

ATEX version

The Ex model in the is suitable for zone 20, 21 or 22 inside the duct and zone 21 or 22 outside the duct.

Skonfiguruj własne rozwiązanie.

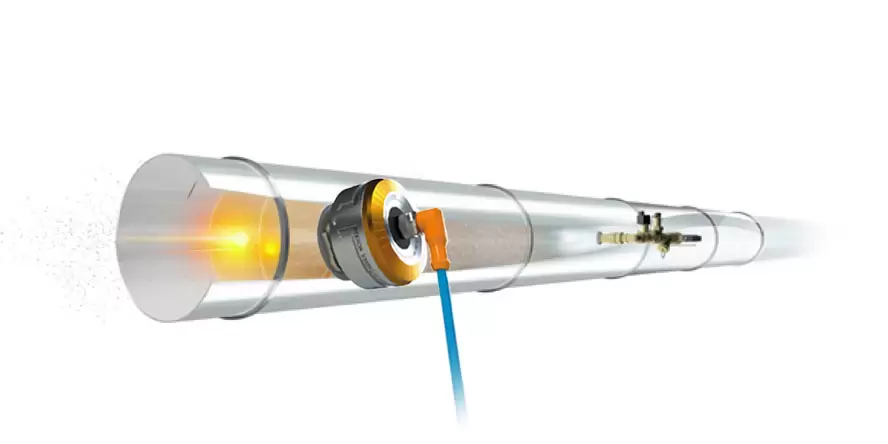

Reliable method for monitoring dust concentration: inductive electrification

The principle of dust measurement is extremely simple, which only enhances the sensitivity of the device providing high measurement accuracy. The most important part of the dust meter is the probe which is placed inside the duct, perpendicular to the air flow. When dust particles moving inside the channel pass or hit the sensor probe, a signal is induced. It is then transmitted to the monitoring system, for example to a computer with monitoring software. In addition to its high sensitivity, this technology also minimises the impact of sensor contamination, process temperature variations and flow velocity on measurement results. Inductive electrification technology enables a detection limit of just 0.01 mg/m3 to be reached.