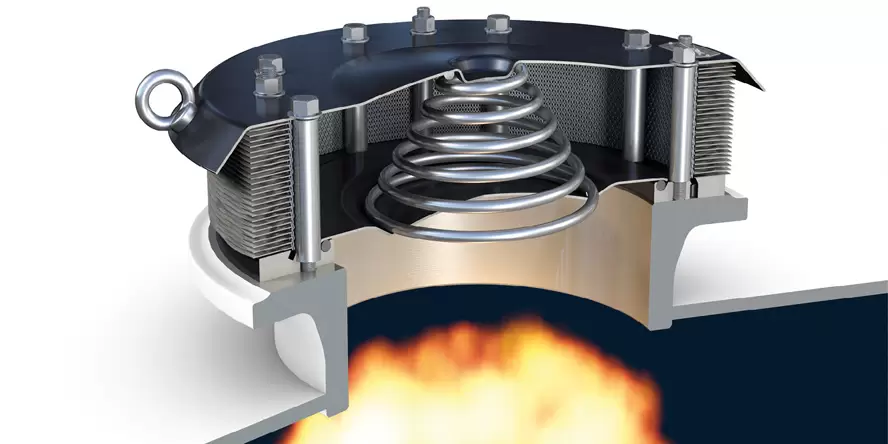

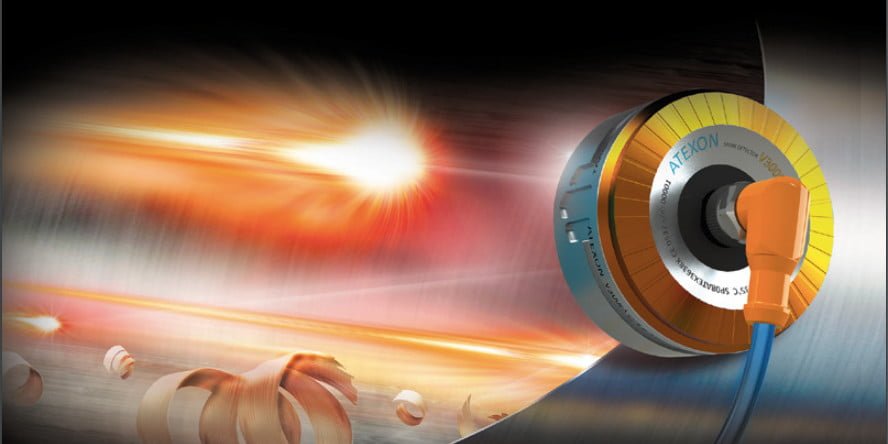

EVN type explosion relief valve

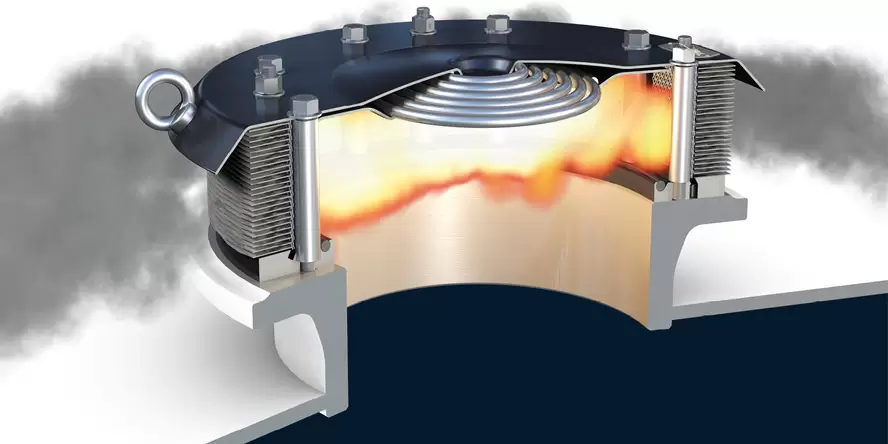

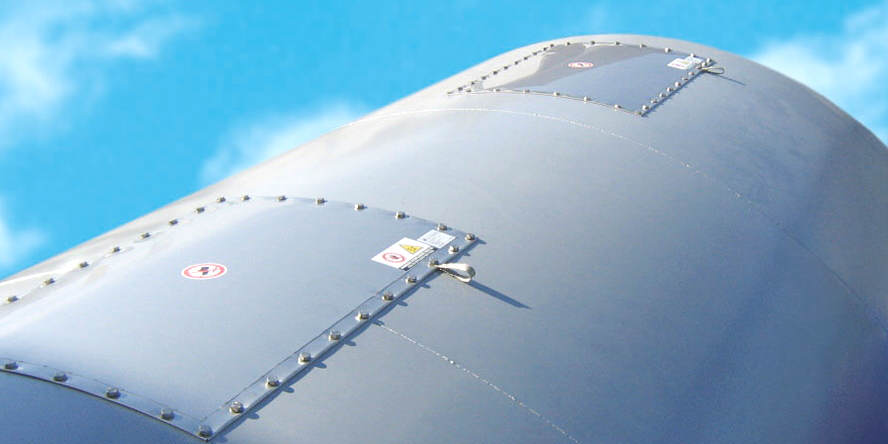

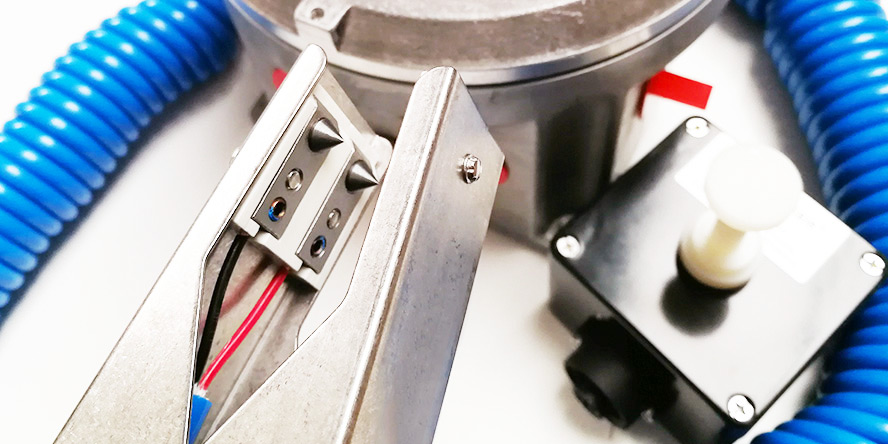

The EVN venting valve is one of the best solutions available on the market for flameless explosion venting. Compact dimensions allowing for low-profile mounting, lightning-fast response to an explosion, high efficiency in pressure release and flame extinguishing, and an automatic valve closing mechanism after explosion venting – these are undoubtedly the most important advantages of the EVN valve.

Unique features:

Closes immediately after venting, eliminating oxygen access and the risk of ignition

Unrivaled dimensions compared to traditional explosion venting systems

Round design ensures radial pressure release and flame extinguishing, increasing efficiency

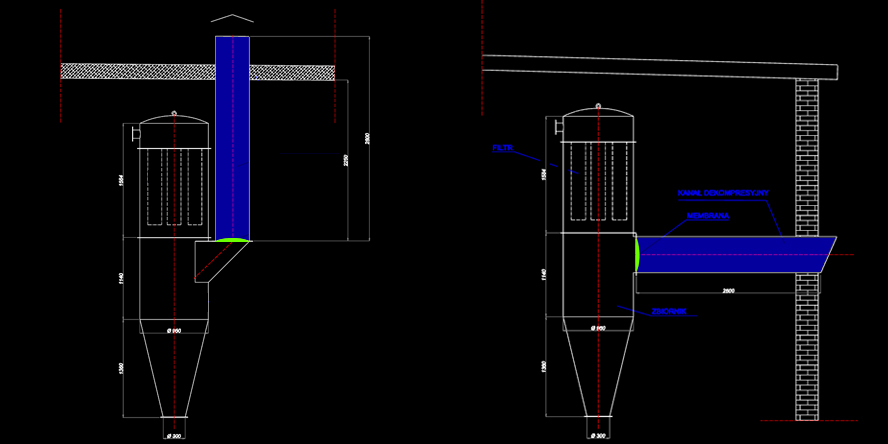

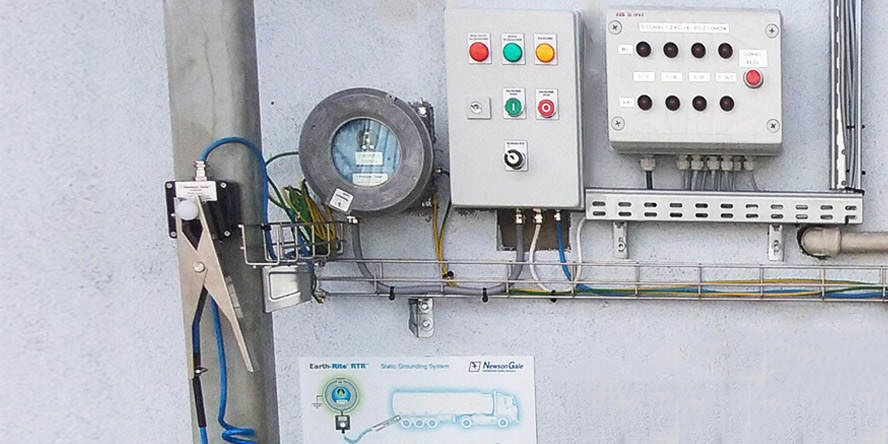

EVN type explosion relief valves provide optimal protection for personnel and equipment in industrial plants. The design of the valves allows for flameless explosion venting in the apparatus, enabling their use (following appropriate guidelines) inside factory rooms. An additional advantage of these designs is the limitation of combustion effects leakage and the reduction of the high explosion temperature.

EVN valves are multi-use protections characterized by excellent vibration resistance and full resistance to negative pressure.

EVN valves have been tested for the following groups of dust: starch, plastics, resins, toners, sugar, wood, MDF, cellulose (fibrous dust), as well as coal and peat.

Basic technical specification:

- KSt max 300 bar * m / s

- Max. overpressure, Pred max.: 2,0 bar

- Operating pressure: 0,2 – 1,0 bar

- Opening static pressure Pstat = 0,05 bar +/- 20%

- Max. surface temperature Tmax = 270 °C

- Max. noise level: 115 dB (A) at 15 m