Prices of ATEX lighting for use in hazardous areas

The cost of EX luminaires designed for hazardous areas is just one element that affects the overall costs of creating a lighting installation. In many cases, labor and materials costs for installation can account for up to several tens of percent of the final price. Therefore, by selecting the right ATEX luminaire tailored to the needs of a particular project, you can significantly reduce its total costs.

Impact of choosing so-called explosion-proof lamps on lighting installation costs

Before introducing the ATEX luminaires to the market, we had extensive experience in designing and installing industrial lighting, including in hazardous areas. For over 10 years, we built lighting installations using luminaires from various manufacturers, which allowed us to gain insight into their advantages and limitations that affect the total investment costs.

It became clear to us that the choice of a luminaire significantly affects the number of luminaires required to illuminate a given space, the speed and complexity of their installation, as well as the consumption of installation materials such as cable trays, power cables, or junction boxes.

Here are some aspects that can significantly increase costs:

- ATEX lamps for use in hazardous areas are 2-3 times more expensive than industrial luminaires.

- Lighting installations in hazardous areas require the use of more expensive ATEX junction boxes.

- In many cases, basic lighting fixtures also serve as emergency fixtures, which require the use of non-combustible and therefore more expensive cables and junction boxes.

- Some industries require the use of stainless steel installation materials, resulting in higher costs for junction boxes, cable trays, and other components.

Considering the above aspects affecting the total cost of a lighting installation intended for hazardous areas, we designed the ATEX OptiLine luminaire to:

- Minimize the number of luminaires needed to illuminate a given space.

- Eliminate the need for junction boxes.

- Minimize the quantity and length of power cables.

- Minimize the length of cable trays and other installation materials.

- Speed up installation through:

- Zero loose parts (diffuser and internal mounting plate on hinges; integrated clips with the diffuser, non-lost screws)

- Ample internal space for easy electrical connection

- Elimination of junction boxes

- Ability to use larger-diameter power cables

Choice of ATEX luminaire

We are not only manufacturers of so-called explosion-proof luminaires but also specialists in the design and installation of industrial lighting systems. Our experience has allowed us to identify common issues related to the installation of ATEX lamps that increase overall investment costs. Based on these observations, we have developed an extremely versatile lighting fixture designed for both Ex general lighting and Ex emergency lighting, while maintaining reasonable production costs.

Below are the key features of the ATEX OptiLine lighting fixture that contribute to reducing the costs of general and emergency lighting installations in the industry. These features simplify the design, installation, and subsequent electrical testing of these fixtures.

Combining general and emergency lighting functions

EX LED lamps from the OptiLine series can serve both as general and emergency lighting fixtures, eliminating the need for separate installations for these two functions. Importantly, emergency lighting fixtures powered from a central battery (OptiLine CBX/CBY model) or lighting fixture powered from an internal battery (OptiLine A1 model).

Wide range of light output options

ATEX OptiLine luminaires with general and emergency lighting capabilities come in two lengths (670 and 1276 mm) and offer six power levels (20, 25, 30, 38, 48, 58 W). Combined with three different diffuser transparency (details below), this provides a wide range of light outputs ranging from 2900 to over 10000 lumens.

Three different diffusers for various applications

EX LED lighting fixtures from the OptiLine series offer a choice of three different diffusers:

- Transparent diffuser is primarily suitable for areas requiring high light output, often used outdoors or in large indoor spaces.

- Frosted diffuser is an excellent choice for outdoor use when reducing glare is important or in areas requiring a strong yet diffused light.

- Opal diffuser provides pleasant, diffused light without glare, offering significant flexibility in light output and lamp characteristics.

Directional light adjustment using lenses

OptiLine EX luminaires allow the use of lenses to change the direction of emitted light. This solution provides tremendous flexibility during installation.

How does it work?

Unlike most lighting fixtures that require special brackets to direct light to specific objects, such as valves, fire extinguishers, or switches, the ATEX OptiLine lighting fixture does not require additional mounting accessories. It can be easily installed in accessible locations, selecting from 22 different lenses to direct light as needed.

Transforming the ATEX OptiLine luminaire into a High-Bay fixture

By using a special lens that concentrates light, these lighting fixtures become suitable for installation at increased heights. In many cases, this eliminates the need for High-Bay luminaires or special structures to lower the mounting point of the luminaire. As a result, this reduces costs and allows for the consistent use of one type of lighting fixture throughout the space.

Variable light output in emergency mode

Each ATEX OptiLine lighting fixture can be individually configured to emit different levels of light output in emergency mode. This feature increases flexibility in designing the lighting system and positively impacts installation costs.

Customized fixtures for efficient connections and savings

The design of many lighting fixtures imposes limitations on the number and size of cable glands that can be mounted on their bodies. Some fixtures allow the installation of only one M20 gland or even have a factory-installed power cable.

The Ex OptiLine lighting fixture can accommodate up to four M20 or M25 glands (two on each side), enabling versatile connections between fixtures without the need for junction boxes.

Larger gland size in the OptiLine ATEX lighting fixture means more wiring options

The ability to use M25 glands in the ATEX OptiLine lighting fixture allows the use of larger cross-section cables. This provides flexibility in selecting cable manufacturers and the option to use thicker non-combustible cables.

Furthermore, the larger gland diameter allows the use of larger conductor cross-section cables to reduce voltage drops along their length. This is particularly important for emergency lighting fixtures, where cables operate at temperatures exceeding 600°C.

Effective and safe installation of ex fixtures

Another advantage of ATEX OptiLine fixtures for hazardous areas is their well-thought-out design without loose components. The luminaire’s diffuser and internal mounting plate, which houses the LED module, are equipped with hinges, eliminating the risk of falling during luminaire installation and electrical testing.

Opening the diffuser requires disconnecting metal clips on one side of the luminaire. Since this is an ATEX fixture, compliance with regulations requires the use of a tool to open it. In this case, the clips are designed to be easily opened with a single screwdriver motion. The clips are integrated with the fixture so they cannot be lost.

If necessary, both the diffuser and clips can be completely detached.

Opening the mounting plate, beneath which electrical connections are hidden, is as simple as turning just two screws. Thanks to a specially profiled screw head, this can be done by hand or with a screwdriver. Importantly, the screws are secured against falling out (“non-lost screws”).

This configuration provides convenient and quick access to electrical components, including cable connections, for quick power supply connections.

Additionally, you can be sure that no element will accidentally fall during installation. This not only increases convenience by freeing up your hands during installation but also enhances safety. A lost screw during installation could not only contaminate the products being manufactured in a factory but also potentially lead to equipment failures or, in extreme cases, pose a risk of creating mechanical sparks that could ignite the explosive atmosphere.

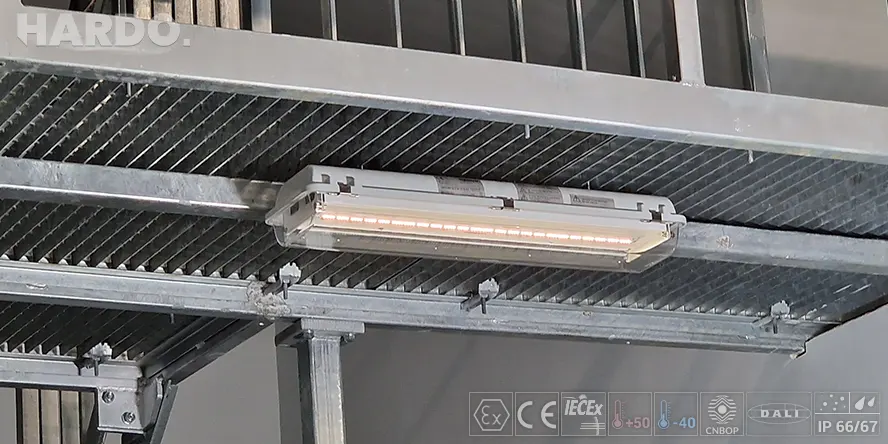

LED luminaires for ATEX zones

Explosion-proof lighting fixtures from the OptiLine series have ATEX and IECEx certifications, ensuring their safe use in Zone 22 (dust) and Zone 2 (gases and vapors) environments at risk of explosion.

Mechanical durability and IP protection class

The high impact resistance of these luminaires has been confirmed through testing in accordance with the PN-EN IEC 60079-0 standard. The luminaire also features a high IP protection rating of 66/67. These characteristics guarantee the robustness and quality of the housing and diffuser, ensuring their long-lasting and reliable operation.