Recently, the engineers of GRUPA WOLFF have implemented two unusual projects in the field of electrostatic discharge earthing.

The first order concerned the delivery and installation of two earthing control systems for tankers as equipped with a valve lock that will be actuated only at unloading of specific material.

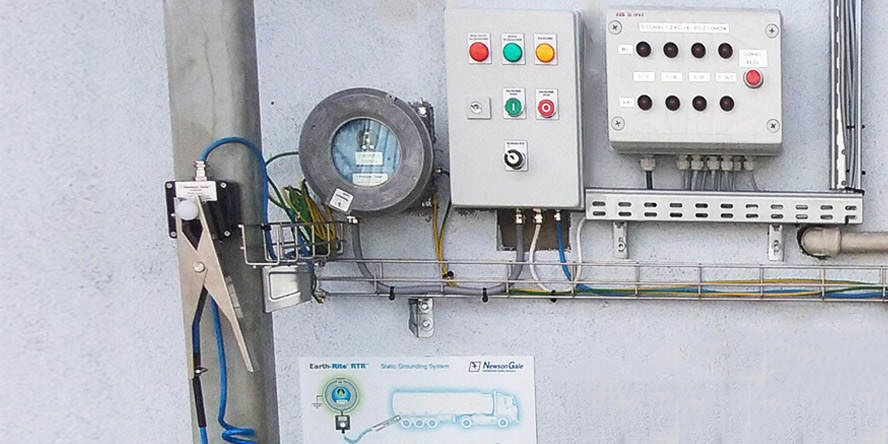

The road tanker unloading stations where flammable and explosive substances are supplied are equipped with the so-called earthing control systems. Their task involves taking off the built-up static electricity from the vehicle, which reduces the risk of electrostatic flash-over that otherwise could lead to ignition of the potentially explosive atmosphere.

The system supplied by GRUPA WOLFF not only informs the operator about the earthing state in a visual way, but also has potential-free contacts that are used for controlling the unloading valve. The system does not allow for the opening the valve until it detects that the tanker is earthed properly.

At the plant for which the delivery was carried out, there are two independent systems of unloading road tankers. The unloading is carried out using air preparation systems.

At each of the planned stations, there will be unloaded both flammable substances for which earthing continuity control is required, as well as the substances that do not present an explosive hazard. The customer sought a solution that in the case of unloading a tanker with a non-explosive medium will enable opening of the locked valve without testing the electric capacity of the tanker.

So, the engineers of GRUPA WOLFF have made an additional automation system that will allow disabling the lock by a special switch protected with a key; thus the risk of unlocking the valve by unauthorized persons has been minimized.

The other order concerned the delivery and installation of the system for discharging static electricity from the vehicles unloading wood dust.

In addition to the standard features of the Earth Rite Plus earthing system, the customer required that the system be equipped with sound signalling which will clearly (i.e. not only via LEDs) indicate the breaking the earthing. In this case, the decision was made to use an additional automation system. The order required designing an individual system control solution which was combined with the earthing control system.

As a result of the work carried out, the earthing system has been calibrated with the sound signalling which – in the case of breaking the connection, e.g. as a result of disconnecting the earthing – will trigger a continuous beep.

With this solution, the operators will have a better control over the state of the earthing of the tankers at unloading.