Industrial Central Vacuum Systems

Central Vacuum Cleaner Systems

We design, build, install and service central vacuum systems for industrial purposes. If a system is destined to handle flammable or explosive dusts, we ensure selection and implementation of adequate protection systems as well as preparing Risk Explosion Assessment Studies or Explosion Protection Documents.

Contact our engineer

We will answer questions about: offer, technical specification, delivery, assembly.

Scope of works performed – central vacuum systems

- preparing concepts and designs for all works

- fabricating the central vacuum and key elements of the system

- developing and implementing control systems

- assembly, start-up and service of the systems

- developing concepts and implementing safeguards limiting the risk and effect of explosion

- working out explosion risk assessments and/or explosion protection documents

Stationary and mobile central vacuum systems

We deliver both stationary and mobile central vacuum systems. As regards the mobile systems, our project implementation scope includes travelling suction and separation units belonging to the class of high-power central vacuum cleaners. Vacuum cleaners are often used for loading and transport of loose, dry and explosive materials. The dust depositing on floors, service platforms, steel structures or process line equipment in the facility is removed by connecting a mobile (travelling) unit to a pipework at the sites specially adjusted for the purpose.

Completed projects – examples

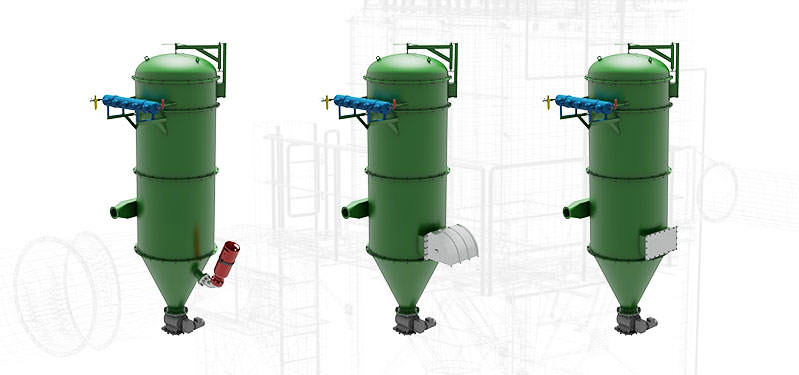

Central vacuum system dust collector protected against explosion effects by flameless explosion venting (Q-BOX) and a decoupling system (non-return damper) A 3d design developed on the basis of the design input for the investment projects implemented in two power plants belonging to the EDF group.

Central vacuum unit in the explosion-proof design (the ATEX version) intended for operation with flammable, explosive and toxic substances.

Central vacuum systems and explosion safety – ATEX

As it has been said above, one of major tasks of central vacuum systems is limitation of the risk of secondary explosions through removal of the so called deposited dusts from the working area. This solution on one hand increases the explosion and fire safety of the plant and, on the other hand, allows to limit the costs related to adjusting the process system to ATEX directive requirements (central vacuum systems allow to limit the explosion hazard area and thereby, to apply less expensive equipment with a lower ATEX certificate).

At the same time, attention should be paid to the fact that in case of flammable and explosive dusts, the central vacuum system must fulfil requirements of the ATEX directive, i.e. to have safeguards limiting the risk of explosions inside the plant and effects of the same.

Note – explosion hazard

According to the statistics, filtration units and cyclones belong to the group of equipment seriously threatened with explosions. According to BIA Statistics – Reports 11/97, filters and cyclones are the second group of equipment most seriously threatened with explosions after silos and containers, and in case of metallic dusts, as much as 44% of all explosions in the industry occur in dust extraction systems). Only silos and tanks are more seriously threatened.

Why apply central vacuum systems

Industrial central vacuum systems are applied for removing deposited dust from floors, flat surfaces and structures of machines and factory shops. It is aimed at maintaining working areas clean and thereby protecting workers, machinery and equipment against adverse effects of dust, including the risk of secondary explosions (in case of flammable dusts) and effects of such explosions.

Major tasks fulfilled by central vacuum systems:

- protection of workers’ health and lives against harmful effects of dusts

- protection of machinery and equipment against damage caused by dust interference

- protection of systems and workers