WOLFF GROUP completed the first stage of a project aimed at adjusting a plant producing bathroom fittings and sanitary equipment to the requirements of explosion and process safety.

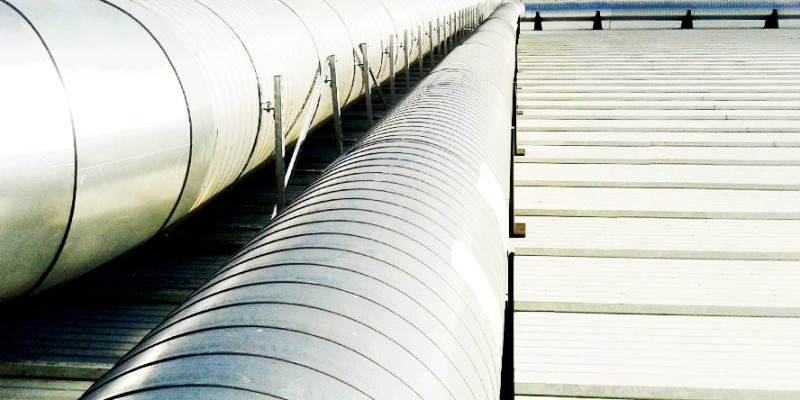

In one of the four rooms, a supply and exhaust ventilation with heat recovery of 36 thousand. m3/h was installed. The task was implemented on the basis of ventilation centre with a cross-flow exchanger and an electrical heater section and sections of rough and precise filtration.

The installation comprised a full set of pipelines and ventilation ducts, together with fittings for air intake and distribution – air grates, diffusers and laminar inlet vents.

Also, a central vacuum system equipped with self-closing flap valves, to which cleaning kits may be connected, was installed in the production hall. The vacuum cleaning system is also used to pull off remains of hand grinding, drilling and machining of the manufactured elements.

In the framework of the project, ventilating and dedusting devices were adjusted to ATEX directives.

SCOPE OF WORKS: design and production of ventilation systems for a plant producing bathroom fittings and sanitary equipment

LOCATION: Poland, Wielkopolskie Province