Dust sensors

both for dust monitoring in ducts (e.g. in the clean air duct of a dust extraction plant), and for dust measurement in production halls, rooms and larger production areas.

The selection of the optimum dust sensors can be preceded by an on-site inspection, which is particularly useful when you want to use dust sensors for explosive areas. As part of our all-in service, we also provide you with delivery, installation as well as subsequent service.

Mounted directly

at the measuring point

Start-up and calibration yeses only eight minuteses

Low-cost operation – virtually maintenance-free equipment

Dust sensor

The dust sensor is designed to measure the total concentration of suspended particles in airflows with velocities >3ms inside conductive pipes and ducts. The dust measuring device is virtually maintenance-free, and its probe is placed directly at the measuring point making it unnecessary to take air samples and test them in a separate room. This all adds to the accuracy of the measurement, but also to low-cost operation.

Room dust sensor

The sensor continuously measures dust in production areas, including explosion hazardous areas (ATEX certified). Thanks to the built-in autostart function, as well as the light indication function, the device can operate completely independent of external systems (simply plugged into the power supply). For more demanding users, the sensor provides communication with a PC, control panel or control room. This can be done via cable or wirelessly. The free software allows you to manage many different sensors from one place.

ATEX Dust detector

The ATEX dust meter is designed for use in harsh industrial environments (including explosive atmospheres) to monitor dust levels in ducts and pipelines. It is most often installed on the clean side of the filters and is used to monitor the correct functioning of the dust extraction units. This allows damage to the filter bags to be detected immediately

Use of dust sensors

The dust meters are designed for monitoring dust levels in ducts with airflow rates above 3 m/s and within halls and other production areas. They provide an extremely wide detection range depending on the dust, this ranges from 0.01 mg/m3 to several g/m3. With a range of several products series, which differ primarily in the design (standard or modular), scope of application and ATEX certification, we are able to supply dust sensors for virtually any industrial application. You can rely on our solutions for both monitoring dust concentrations to protect worker’s from respirable dust, and for the use of equipment as part of explosion prevention systems.

We select sensors for individual systems, ducts and rooms

We create a sensor network based on wired and wireless communication

Detectability

Measurement

Protection rating

Humidity

ATEX version

Dust sensors are perfect

for monitoring the filtration and dedusting process

You control the filtration process

By installing dust sensors in the clean air duct, you will immediately detect damage to the filter bags in the dust collector

Read more

It is natural that filtration inserts become damaged over time and need to be replaced. Thanks to pollution sensors, you will immediately detect when the filter needs to be replaced due to damage. You will diagnose any leaks and damages that cause the channel of clean air to continue flowing with polluted air.

You prevent explosions

Faulty dust extraction processes for explosive dust create explosion risks close to workplaces. With sensors you act preventively and minimise this risk

Read more

When dealing with dust extraction in an industrial plant, which can create an explosive atmosphere when mixed with air, it becomes extremely important to control the condition of the filters as a preventive measure against explosions. If the dust extraction units are faulty, you risk creating an explosive atmosphere in the channel of clean air that is directly supplied to the workstations. In such a situation, even a minimal spark can cause an explosion near the employees. By monitoring the pollution in the channels of clean air, you are acting preventively.

You care about the health of your employees

You yese care that dust extraction really does its job and provides employees with safe working conditions.

Read more

Many dust particles have respirable properties – their size is below 7 µm, which allows them to penetrate into the gas exchange area. Diseases caused by these particles can lead to serious chronic illnesses and, in extreme cases, even death. By controlling the efficiency of the dust extraction system, you ensure that the air at workstations is free from harmful dust particles that can pose a risk to health.

Where can you install room dust sensors?

On the shop floor

Example from the photo: a hall with hydraulic presses for processing aggregate minerals and stones

Near mixers

Example from the photo: measurement near the aggregate mixers at an interior finishing surface manufacturer

Near the silo hopper

Example from the photo: dust monitoring near the unloading hopper of a sugar silo

On conveyor belts

Example from the photo: transport of sugar by conveyor belts from the silo to production

Industrial-scale agriculture

To demonstrate the extremely wide range of applications, we show the use of the sensor on a poultry farm to prevent the release of dust into the environment

We will network the sensors (wired or wireless)

Regardless of whether the sensors will be mounted in easy or hard-to-reach locations, access to configuration changes, information on the current measurement, as well as dust trends over time, will be readable using the free software included with the sensors. Importantly, you will create a software-managed sensor network based on both, wired and wireless connections. This freedom of sensor connection allows for:

-

- virtually unlimited installation location options even in difficult or impossible for wired connections

- investment cost – it is worth comparing, what the cost of cables and cable installation will be in relation to the cost of optional wireless communication

- the possibility of creating a sensor network consisting of both, wired and wireless connections.

Which areas to include in dust monitoring?

Does your site run several different halls and rooms, with different equipment and entire plants? Or you have one hall, but you are not sure what you should monitor in terms of dust concentration and how?

We understand your concerns, so feel free to invite us for an on-site visit of your production facility, so that we can advise you on which areas of the plant should be covered by dust monitoring, together with information on what type of dust sensors are needed in each of the designated areas and what purpose they will serve (health protection against respirable dust, preventive explosion protection).

You will immediately see when the standard value is exceeded

Immediate indication of exceeding alarm conditions is one of the key functions of the sensors influencing the response time of employees in relation to the detected threat. The signal of exceeding alarm conditions is not only sent to the control room, but is also displayed directly on the sensor housing by means of integrated LEDs. The LEDs allow an immediate assessment of the safety level by employees who are directly in a place where dust that is hazardous to health and/or from the point of view of the ATEX Directive may occur.

CASE STUDIES

Stories of our clients

APPLICATION OF SINTROL DUST SENSORS

Dust monitoring system in industrial conditions

If we were to name the general use of dust sensors, it could be said that it is a system monitoring dust in industrial conditions. Whether you need to measure it in ducts (e.g., in dedusting units) or in rooms, among the solutions offered by Sintrol, you will find the right one for your needs.

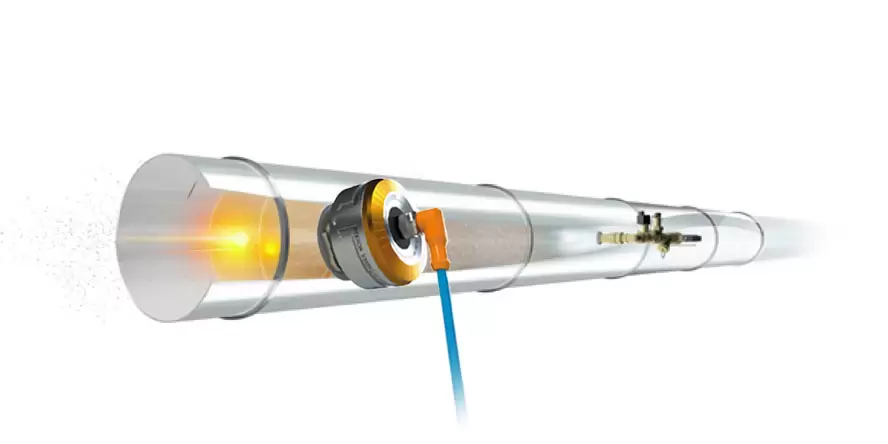

Measurement of industrial dust concentrations in ducts

The most important feature of this solution is the probe, which is placed directly in the duct at the measurement point. The dust concentration is determined based on the reliable and very accurate method of inductive electrification.

Workstation dust measurement

Sensors allow monitoring of dust concentration, e.g., in ventilation and dedusting system ducts, which supply air to workstations. One of the basic functions of this type of measurement is a quick diagnosis of whether harmful respirable dust flows with the air flowing to workstations, which can affect proper lung function.

Control of bag filter damage

The above-described measurement of dust concentration in ducts supplying air to workstations is most often performed on the clean side of dedusting units. Sensors allow for the rapid detection of bag filter damage, which is most often the cause of the mentioned dusting.

ATEX dust signaling device

Many industrial dusts (e.g., sugar, flour, cocoa, wood, cellulose, many metals, or paracetamol) are explosive. Therefore, damage to filter bags not only returns dust-laden air to workers but also poses a real explosion risk on the clean side of the filters. ATEX dust signaling devices installed behind dedusting units act preventively and allow detecting the emerging explosion risk.

Production hall dust monitor

Another proven application of dust sensors is monitoring the dusting of halls and production rooms. Specifically for this purpose, the manufacturer – Sintrol – designed a universal sensor for rooms and larger devices such as belt conveyors. Just as in the case of measuring dust concentration in ducts, the measurement is carried out directly at the installation site – the dust monitor has a fan that draws air into its interior, where the probe is located.

Measurement of dust concentrations in explosion hazard zones

Similarly, within ducts, local explosion hazard zones may appear around some larger installations and production devices. Dangerous places are often dumps from silos or the transport of dusty products by belt conveyors or bucket feeders. In such situations, it is advisable to monitor the concentration of explosive dust, which can be done with the same sensors as measuring dust concentrations in entire rooms.