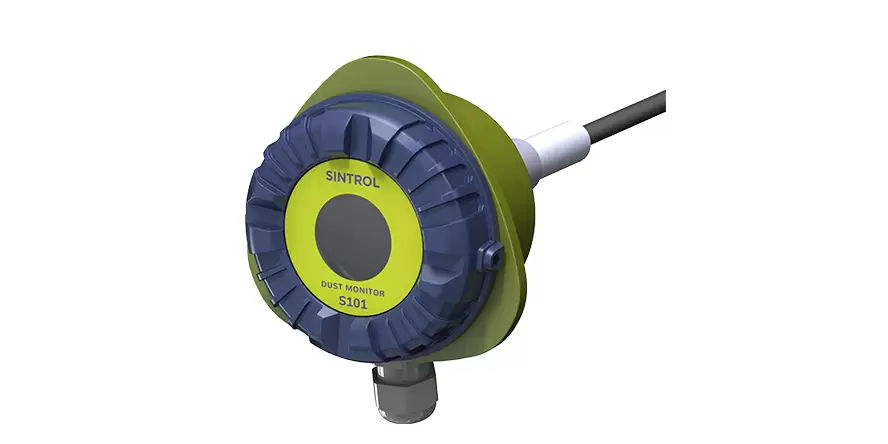

Dust sensor (dust sensor)

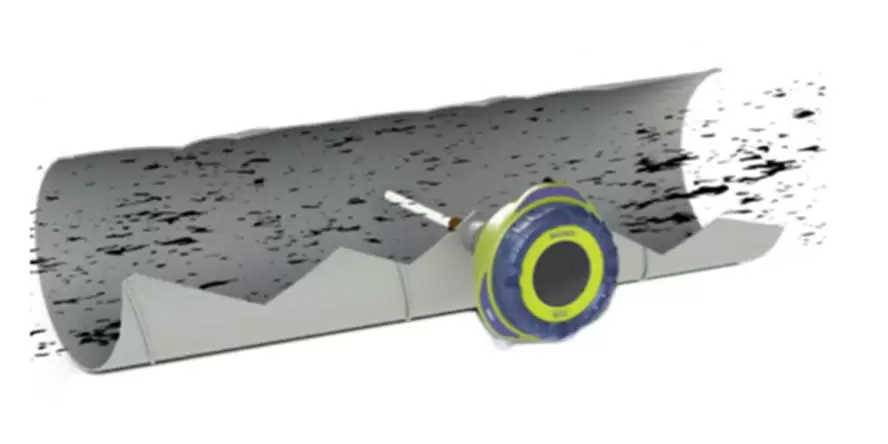

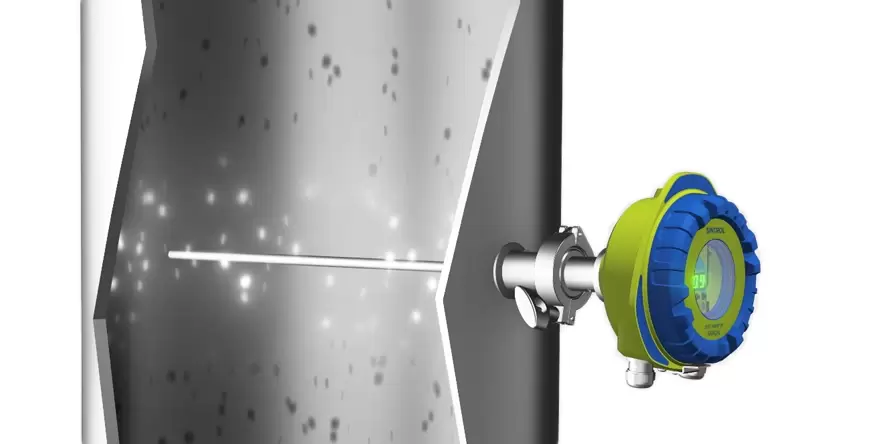

for installation on ducts and pipelines

The dust sensor is designed to measure the total concentration of suspended particles in airflows with velocities >3ms inside conductive pipes and ducts. The dust measuring device is virtually maintenance-free, and its probe is placed directly at the measuring point making it unnecessary to take air samples and test them in a separate room. This all adds to the accuracy of the measurement, but also to low-cost operation.

The sensor is available in two versions:

- The S200 series – has a modular design, allowing the electronics, as well as the probe, to be adapted to virtually any industrial conditions,

- The S100 series – is the budget version, without the possibility of modification, intended for standard applications.

Dust sensor parameters

The S200 dust sensor will work in any industrial environment! It provides exceptional and reliable measurement sensitivity, achieved thanks to the manufacturer’s use of the latest electronic systems and interchangeable probes.

| Measurement | Total suspended particles |

| Measurement principle | Inductive electrification |

| Range | Detection limit from 0.01 mg/m3 to several g/m3 (depending on the type of dust) |

| External surfaces | Satin 180 mesh. Sandblasting or electropolishing is also available on request. |

| Serial communication | RS485, USB |

| Communication protocols | Modbus RTU (RS-485) Sintrol network (USB, RF and RS-485) |

| Output signals | Two potential-free contacts for signaling exceeding set levels: alert and alarm. |

| Power supply | 24VDC +-10% or 100...240VAC +-10% 50/60Hz |

| Protection degree | IP 66 |

| Temperature | Ambient: -40°C...+60°C (-30°C...+60°C for Ex models) Process: max. 300°C (using a special high-temperature process connector max. 700°C) |

| Temperature for Ex models | Ambient: -30°C...+60°C Process: max. 200°C |

| Pressure | 6 bars (Using a high-temperature process connector reduces the maximum process pressure to 3 bars) |

| Humidity | max. 95% relative humidity (without condensation) |

| Visual dust status check | The sensor front is equipped with an LED that lights up in green, yellow, and red according to the current dust status |

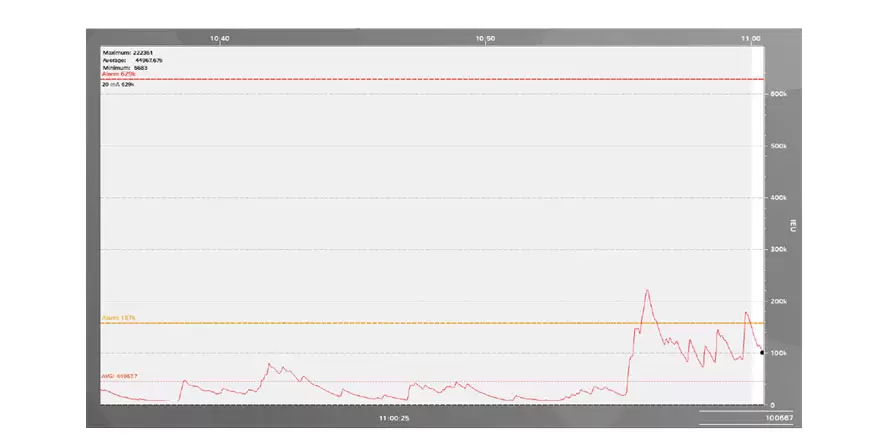

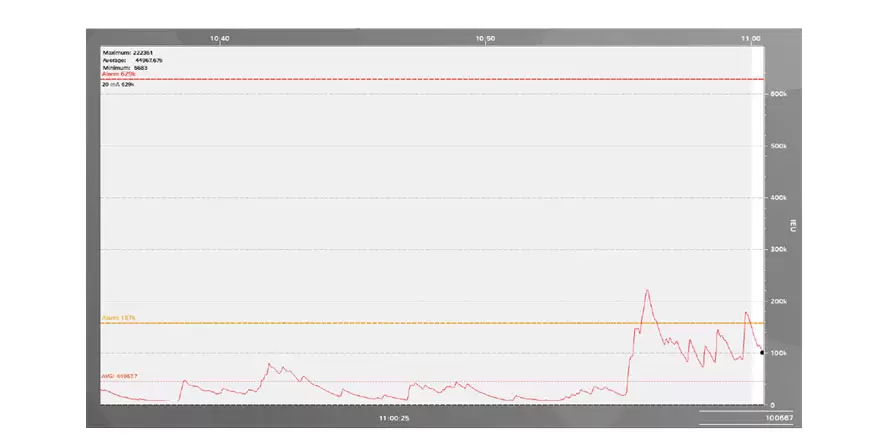

| Management and configuration software | DustTool Software allows for immediate sensor configuration, managing multiple sensors from one place, and examining dust level trends |

Dimensions – front view

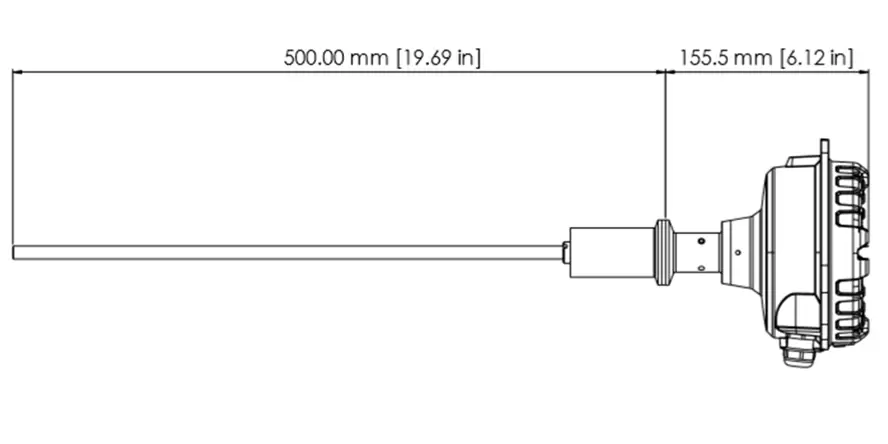

Dimensions – side view (the length of the probe is matched to the diameter of the channel)

| Measurement | Total suspended particles |

| Measurement principle | Inductive electrification |

| Range | Detection limit from 0.01 mg/m3 to several g/m3 (depending on the type of dust) |

| Serial communication | RS485 |

| Communication protocols | Modbus RTU (RS-485) Sintrol network |

| Output signals | Two independent semiconductor relays for signaling exceeding set levels: alert and alarm. |

| Power supply | 24VDC +-10% |

| Protection degree | IP 66 |

| Temperature | Ambient: -40°C...+60°C Process: Max. 250°C |

| Pressure | Max. 200 kPa |

| Humidity | Max. 95% relative humidity (without condensation) |

| Probe length | 250 mm (can be shortened during installation) |

| Visual dust status check | The sensor front is equipped with an LED that lights up in green, yellow, and red according to the current dust status |

| Management and configuration software | DustTool Software allows for immediate sensor configuration, managing multiple sensors from one place, and examining dust level trends |

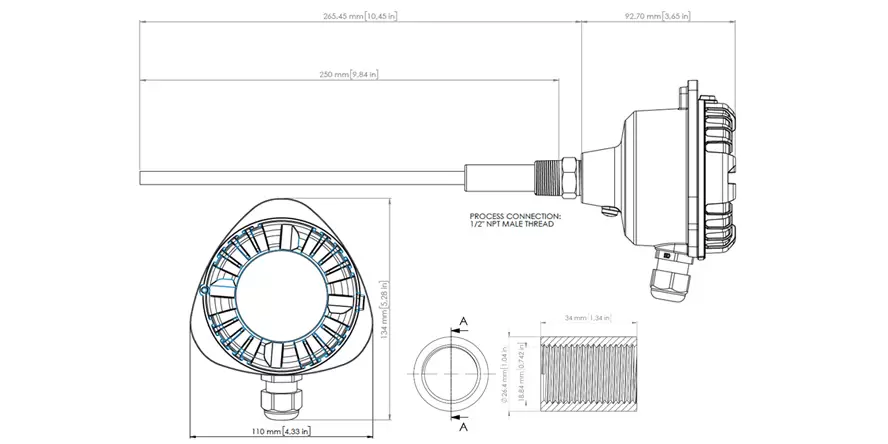

Dimensions

Key features of the dust sensor

Instant calibration

You only need about 8 minutes to have each of the dust meters ready to go, all thanks to automatic configuration and calibration.

Robust design

Robust die-cast aluminium housing with IP66 protection

A proven method of measurement

The reliable method based on inductive electrification provides an extremely wide measurement range with a detection limit of 0.01 mg/m³

Standardisation of measuring devices

Regardless of how many sensors you have and what probes you use in them, you will be able to manage them from one place.

ATEX version possible

The Ex model in the S200 series is suitable for zone 20, 21 or 22 inside the duct and zone 21 or 22 outside the duct.

Configure your own solution

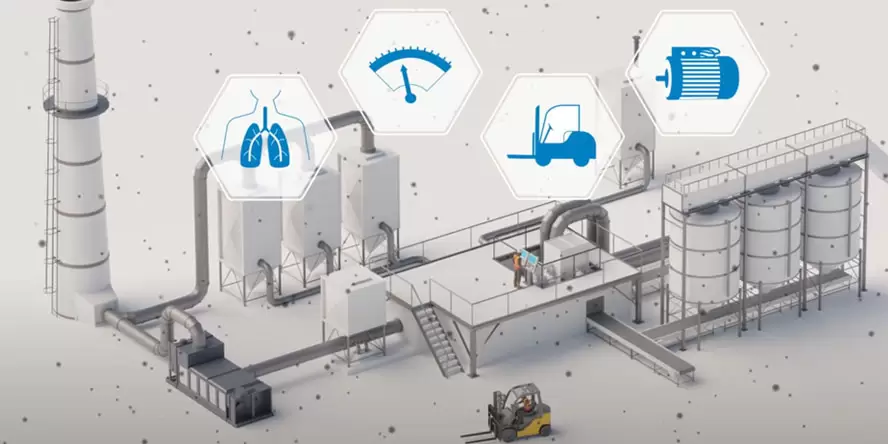

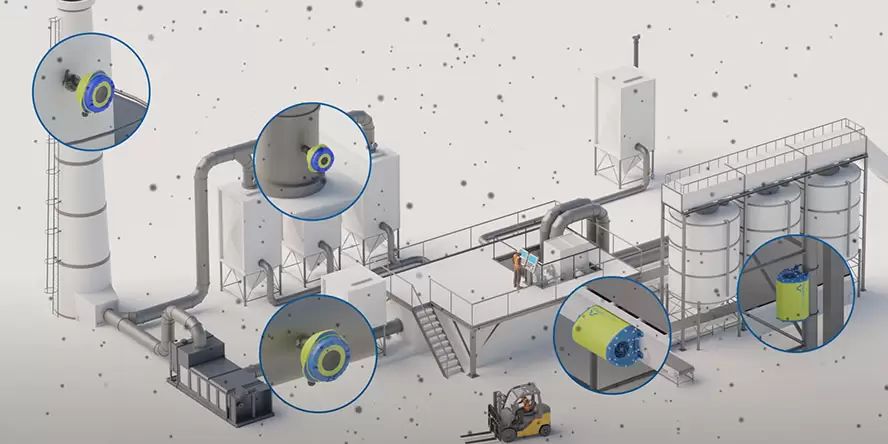

The use of dust measurement and monitoring

in the filtration and dedusting process

Dust concentration meters allow you to monitor the condition of the filters

You will immediately detect filter bag damage or leaks, and in the long term you will optimise the maintenance frequency.

With dust sensors, you minimise the risk of explosion

You act preventively and prevent an explosive atmosphere from forming on the clean side of the filters.

Dust sensors are used to diagnose the quality of air flowing into workplaces

You take care that dust extraction really does its job and provides employees with safe working conditions.

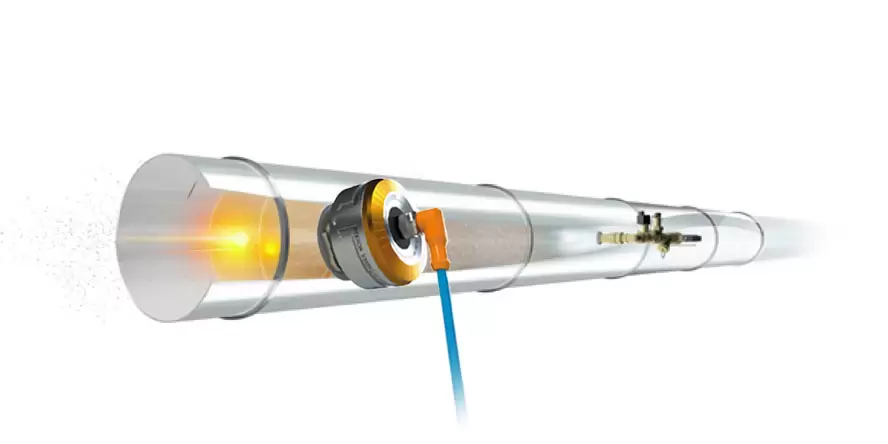

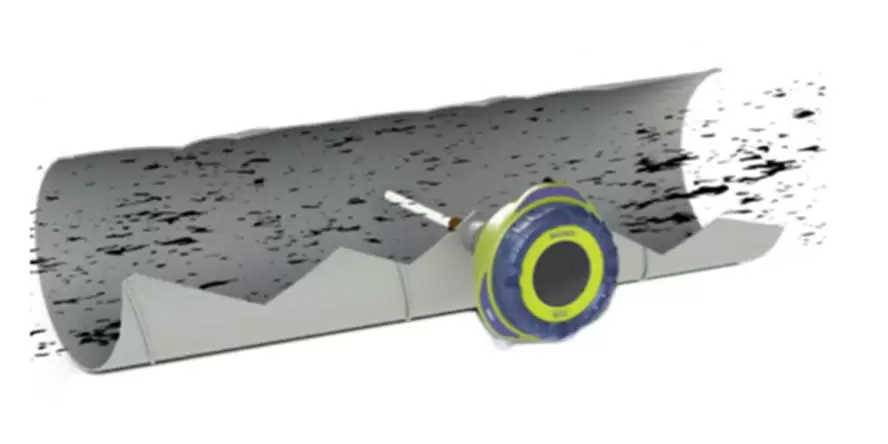

Reliable method for monitoring dust concentration: inductive electrification

The detection of air pollution by dust fractions is based on a well-known and proven measurement method – inductive electrification. It consists of placing inside the duct perpendicular to the direction of air flow, a probe which is passed by, or struck by, the dust grains. This process generates an electrical signal transmitted in real time for analysis, which can be explained simply: the greater the charge, the greater the contamination. Inductive electrification technology enables a detection limit of just 0.01 mg/m3 to be achieved.

Automatic dust sensor configuration

takes only 8 minutes.

Instant, simple and user-friendly configuration is one of the meter’s many advantages. During the automatic configuration procedure under normal process conditions, the dust monitor automatically adapts to the process conditions and sets the measuring range and alarms accordingly. Under normal conditions, the unit will light up green and the mA output will be set to 5% of the range.

The unit can be installed in the contaminated air ducting to the filter as well as in the ducts on the clean side of the dust extraction unit. In both cases, no manual range configuration is required.

The baseline thus determined is always stored in the device’s memory. Then, using a switch mounted in the unit, you can very quickly set one of the three sensor response modes. When the response mode is changed, the device applies the appropriate multipliers to the baseline and automatically adjusts the ALARM and ALERT threshold parameters. All device parameters can also be adjusted manually in the DustTool software.

Use of dust sensors

In a production environment, we often deal with dust. Its negative impact is not only manifested in the risk of explosion. Moreover, many of the dusts present in production do not have explosive properties, yet they still pose a significant threat. They have a negative impact on the health of employees, production efficiency, and shorten the life cycles of machines and devices. By using dust meters, you can assess the level of dust, check the efficiency of dedusting systems, and reduce the aforementioned negative effects of working in a polluted environment.

How we will help you?

We will select the sensor individually, so you will gain the most precise monitoring of dust in the air.

The S200 measurement series is available with a wide range of different probes and process connection options. In their design, new mechanical and electrical solutions were used, which allowed for the standardization of devices, regardless of which probes we choose and whether they will differ from each other in different places in the process. Thanks to this, it became possible to offer you maximum measurement precision, which will be fully adapted to your individual processes and requirements.

For standard needs, we will suggest using the S100 sensor, which will simultaneously reduce investment costs.

We will enable the management of any number of dust sensors.

We will deliver dust meters with all necessary connection accessories and the ability to connect to the manufacturer’s software (remotely via a router or using a USB cable). Thanks to the program, you will be able to configure and manage all dust meters from one place. Long-term dust trend research may also be useful for you, which will optimize the maintenance cycles of machines and devices.