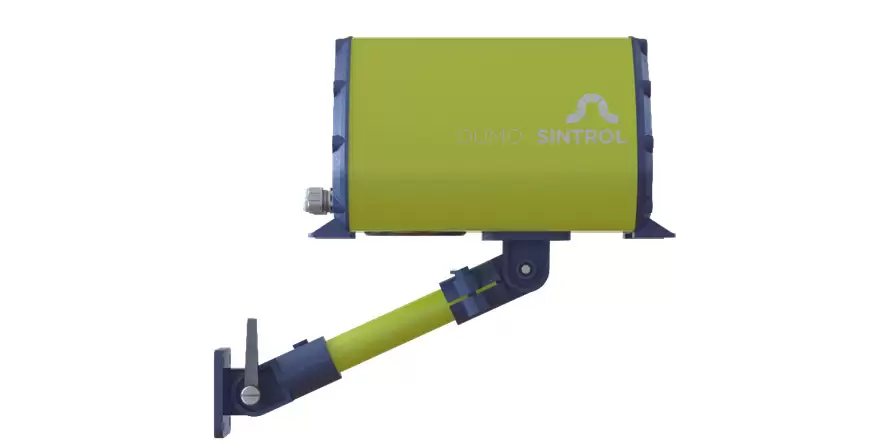

Sensor for continuous measurement of dust concentration in production halls

The sensor continuously measures dust in production areas, including explosion hazardous areas (ATEX certified). Thanks to the built-in autostart function, as well as the light indication function, the device can operate completely independent of external systems (simply plugged into the power supply). For more demanding users, the sensor provides communication with a PC, control panel or control room. This can be done via cable or wirelessly. The free software allows you to manage many different sensors from one place.

Application

- employee health protection

- detection of malfunctioning dust extraction and ventilation systems

- anticipation of equipment failure (e.g. loss of leakage)

- reducing the risk of a dust explosion (keeping concentrations below the lower explosion limit)

- detection of anomalies in the production process

- supporting the maintenance of the cleanliness of the facility

- meeting insurers’ explosion safety requirements

Key benefits

- continuous real-time measurement of dust concentration with recording of results in the device memory

- built-in control panel with keypad and digital display

- free software to configure and manage sensors from a single location (the program can access historic data and allows all sensor operating parameters to be changed)

- funkcja autostartu uruchamiana z poziomu panelu sterowania – czujnik gotowy do pracy po 8 minutesach

- three pre-set sensor sensitivity levels (HIGH, MEDIUM, LOW) accessible from the control panel allow you to change the pre-set parameters from software level

- built-in LEDs to indicate when alarm thresholds are exceeded

- with compact dimensions and a weight of approx. 4 kg, the sensor can be moved periodically to different locations

- stand-alone operation (simply connect the power supply and run autostart) or in connection with a PC, control unit or control room (ports: USB, RS-485; protocols: Modbus RTU, Sintrol Network)

- wireless capability

Where can you install room dust sensors?

On the shop floor

Example from the photo: a hall with hydraulic presses for processing aggregate minerals and stones.

Near mixers

Example from the photo: measurement near the aggregate mixers at an interior finishing surface manufacturer.

Near the silo hopper

Example from the photo: dust monitoring near the unloading hopper of a sugar silo.

On conveyor belts

Example from the photo: transport of sugar by conveyor belts from the silo to production.

Industrial-scale agriculture

To demonstrate the extremely wide range of applications, we show the use of the sensor on a poultry farm to prevent the release of dust into the environment.

Had it been applied, there might not have been an explosion…

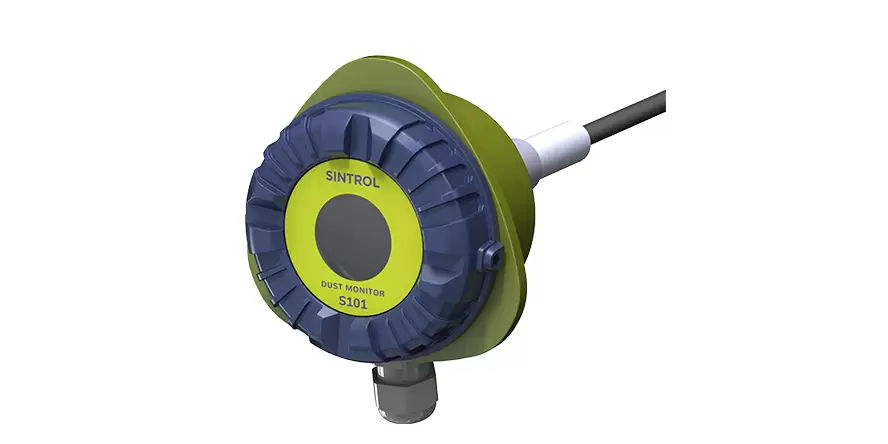

Sensor parameters

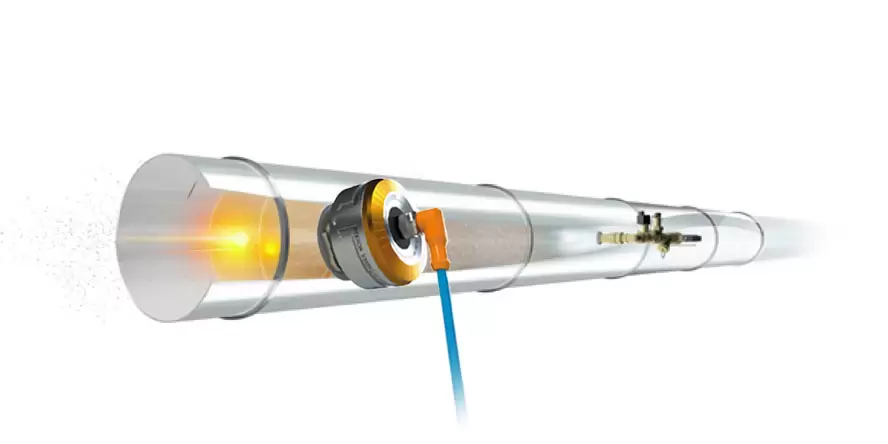

Dust measurement takes place in an internal measurement chamber. The air is drawn into it by a long-life built-in fan. It produces a constant and unchanging flow, which ensures reliable monitoring.

The Dumo Pro dust sensor is virtually maintenance-free for non-hygroscopic dust. If the dust is hygroscopic (e.g. sugar dust) you only need to develop a suitable maintenance schedule. It provides reliable detection of dust particles from PM1 to 200 microns.

| Measurement | Total suspended particles |

|---|---|

| Measurement principle | Induction electrification |

| Range | Detection limit from 0.01 mg/m3 to several g/m3 (depending on the type of dust) |

| Serial communication | RS485, USB, or optional wireless communication |

| Communication protocols | Modbus RTU (RS-485) Sintrol network (USB, RF, RS-485) |

| Output signals | Two potential-free contacts for signalling exceeding set levels: alert and alarm |

| Power supply | 12 - 24VDC +- 10% |

| Protection rating | IP 66 |

| Temperature | Ambient conditions: from -40°C to +60°C |

| Humidity | Max. 95% relative humidity (non-condensing) |

| Energy consumption | To 10W |

| Management and configuration software | DustTool Software allows you to instantly configure sensor operation, manage multiple sensors from a single location and study dust trends |

| Weight | 4,2 kg |

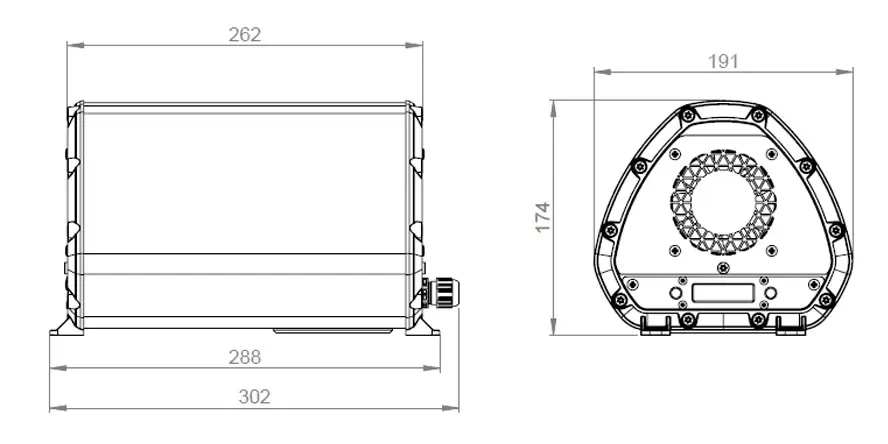

| Dimension | 288 (D) x 191 (Sz) x 174 (W) mm |

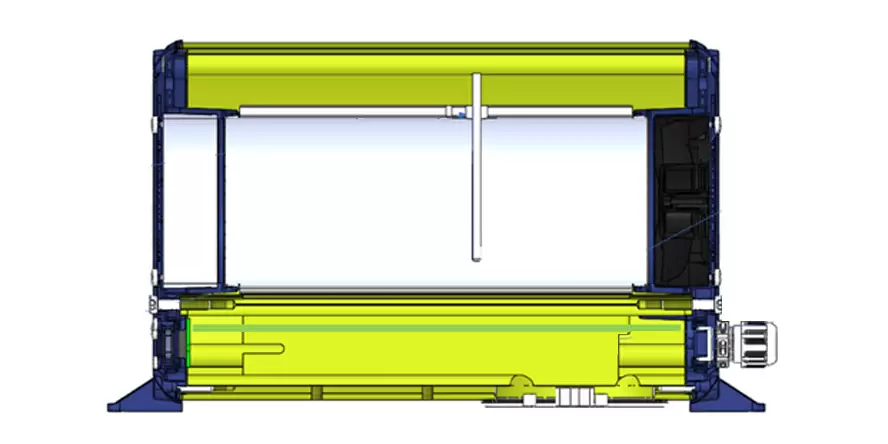

Cross-section

Dimensions [mm]

What to look out for

We will suggest to you what areas and facilities to include in dust monitoring

We can help you select locations throughout your production facility that require ongoing monitoring of dust concentrations in the air. We tell you which of these sites to yese into account to provide workers with clean air at workplaces and which sites require explosion prevention (monitoring the risk of explosive atmospheres).

Built-in display and control panel

The display and LEDs allow you to quickly verify the dust level and whether a warning or alarm condition has been exceeded. The dust monitor also has a built-in keypad which enables autostart and quick configuration from the device (configuration is also possible from a PC, control panel or control system connected to the sensor).

We will give you free software

The control panel built into the unit allows quick configuration of the sensor, but only the free DustTool software will show its full power of capabilities. You will be able to manage all the dust meters from one place and change the factory-set parameters. DustTool also gives you access to archive data that will allow you to optimise machine maintenance cycles and cleaning, as well as predict spills and failures.

You will connect via cable or wirelessly

Wired connection is not only the cost of the cable, but also that of installation. Sometimes the sensor is located at a great distance from the control panel or control room. It also happens that laying of cables requires reaching places that are difficult to access, the use of scaffolding or lifts. In such situations, a wireless connection may prove to be a much better solution. Importantly, sensors communicating wirelessly as well as via cable can work in the same network.

Start up in 8 min thanks to the autostart function

The autostart function allows the baseline concentration in a given space to be measured in 8 minutes and two predefined trip thresholds to be entered (5 and 20 times the baseline concentration). If you want to change these thresholds, you can easily do so from the control panel (selection of predefined values) or from the free DustTool software (enter any values you wish)