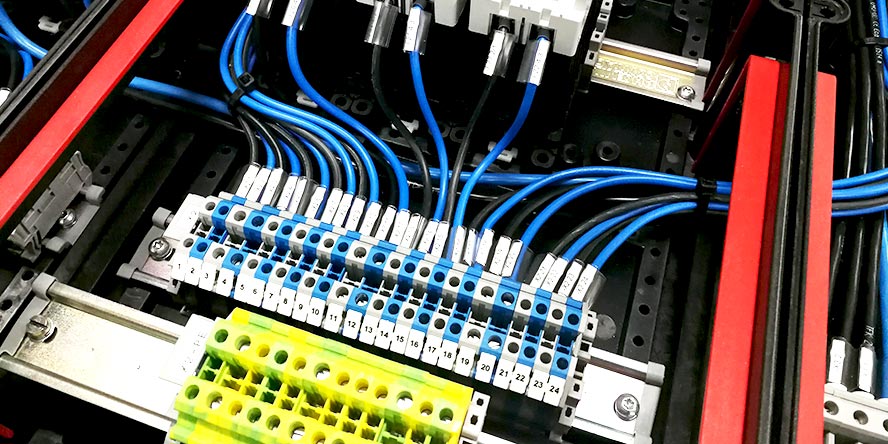

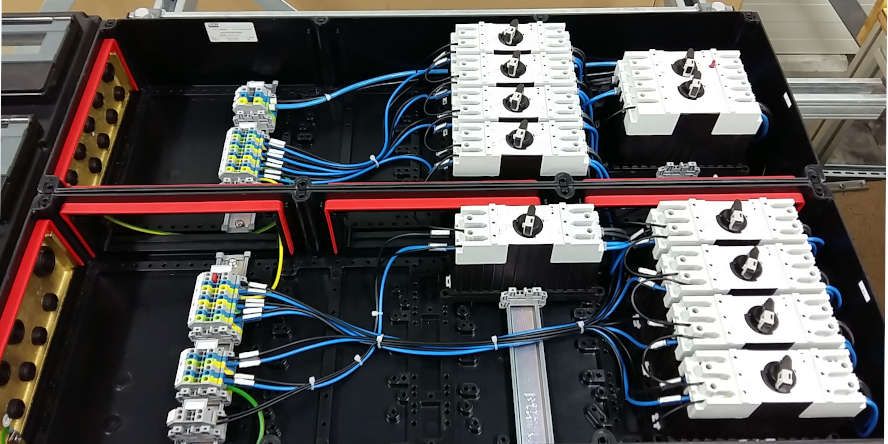

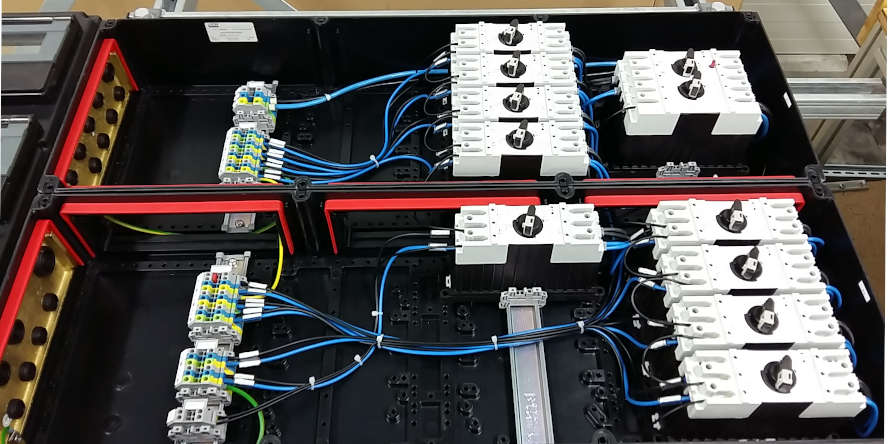

All junction boxes and terminal boxes are designed to meet the essential requirements of the ATEX Directive (94/9/EC). Devices with additional measures to ensure effective protection against the generation of excessive temperatures, the occurrence of arcs and electric sparks, under normal operating conditions and in certain abnormal states, are approved for use in explosion hazardous areas in accordance with PN-EN 60079-7 (Explosive atmospheres – Part 7: Protection of equipment by means of reinforced construction “e”).

Increased insulation clearances of built-in components, high IP rating of enclosures, temperature restrictions, use of certified components and certified electrical apparatus are specific requirements for reinforced construction equipment. All products also meet a number of additional ones before leaving the factory.

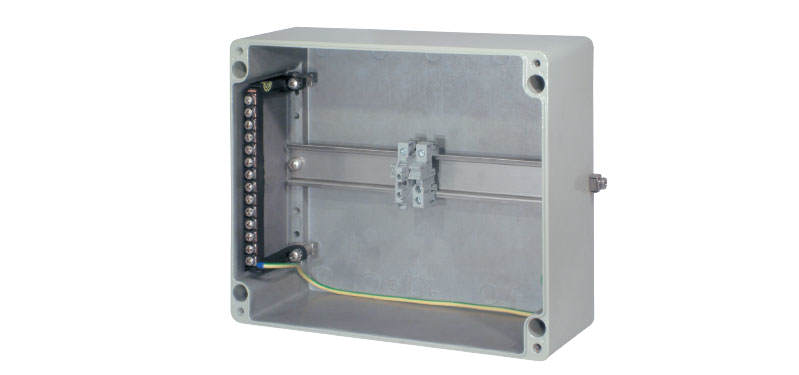

GRP Ex Terminal Boxes – HARDO

Explosion-proof terminal boxes by HARDO provide an excellent alternative to well-known global manufacturers, offering the same (or even better) quality at a competitive price. They are certified for use in zones 1, 2, 21, and 22. All HARDO terminal boxes are equipped with cable glands, terminals, and other components according to the investor's requirements (we can also use components from other manufacturers).

Aluminum Ex Terminal Boxes – HARDO

Explosion-proof terminal boxes of the Polish company HARDO are made of aluminum and are a competitive alternative to well-known global manufacturers in terms of value for money. They are certified for use in zones 1, 2, 21 and 22. All HARDO terminal boxes are equipped with glands, terminals and other components according to the investor's requirements (we can also use components from other manufacturers).

Stainless steel Ex terminal boxes – HARDO

Stainless steel Ex terminal boxes of the Polish company HARDO, are available at a competitive price and workmanship quality compared to the world giants of the electrical engineering market in explosion-proof design. They are certified for use in zones 1, 2, 21 and 22. A wide range of sizes allows our engineers to offer the best solutions according to the needs of the investor and within the limits of the certificates.

Apparatus which do not create arcing or sparking or exceed max. permissible surface temperatures during normal operating conditions can be used in accordance with the European standard EN 60079-7 – „Ex-e“ in hazardous areas of Zone 1, 2, 21 and 22. All junction and terminal boxes are manufactured according to this standard. Terminal boxes can be subsequently re-fitted or upgraded with certified cable glands according to national regulations and the manufacturers recommendations.

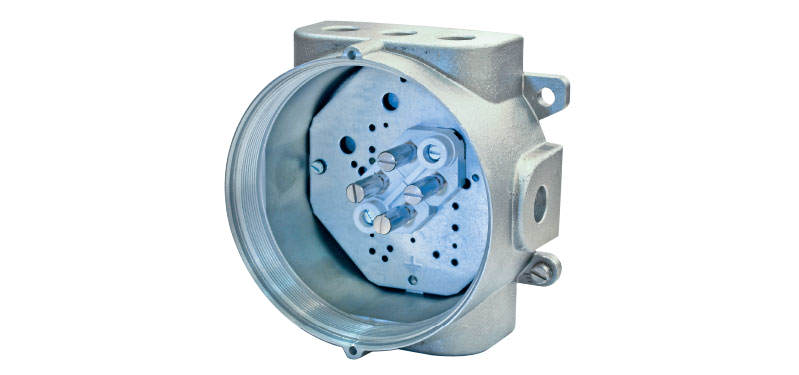

GHG 791 Ex-Junction Box

The robust junction boxes made of plastic and light alloy are featured by their simple mounting and installation capability and their design. They are fitted with pillar terminals for cable of up to 6 mm². The practical orientated housing form allows for problem-free access to the connection terminals for installation.

GHG 793 Ex-Junction Box

The sturdy CEAG junction boxes made of light metal are used to distribute and conduct electricity in Zone 1 and Zone 2 areas with no risk of explosion. Optionally, mantle terminals with a terminal range of 6 mm² are available for these branching boxes. Four M20 threaded holes allow variable equipment with various ducts for cables and lines. Drilled holes, cable and line ducts, through which no lines are conducted, should be closed with certified threaded stoppers.

Universal Terminal Boxes – Plastic version

The terminal boxes were designed for measuring and controlling utilization in Ex-e and Ex-i applications. They are used as a link between the main cable to the control room and the branch cables into the field. In addition to this, they may also be used for the direct connection of actuators and sensors. The new terminal boxes for instrumentation installations are available in 5 sizes, ranging from 6 to max. 60 connection terminals. The optional interior coating protects your data cable connections against external radiation fields. The choice between screw and tension spring (screwless) terminals for single and multi-wire conductors makes it possible for engineers to select the type of connection most suitable for the particular application.

Universal Terminal Boxes – Light alloy metal design

The new sturdy CEAG terminal boxes made of a light alloy metal are used to distribute and conduct electricity in hazardous explosive areas of the Zones 1, 2, 21 and 22. Optionally, all of the modular terminals up to 35 mm² pursuant to EN 60079-7 are available in these terminal boxes. Variable equipment with various cable and line ducts pursuant to customer specification can be realised with the terminal boxes made of light alloy metal. Drilled holes, cable and line ducts, through which no lines are conducted, should be closed with certified threaded stoppers. High chemical resistance of the housing is ensured by the use of impact-resistant plastic powder coating.

Ex-d Terminal Boxes

The new sturdy CEAG terminal boxes made of a light alloy metal are used to distribute and conduct electricity in hazardous explosive areas of the Zones 1, 2, 21 and 22. Optionally, all of the modular terminals up to 35 mm² pursuant to EN 60079-7 are available in these terminal boxes. Variable equipment with various cable and line ducts pursuant to customer specification can be realised with the terminal boxes made of light alloy metal. Drilled holes, cable and line ducts, through which no lines are conducted, should be closed with certified threaded stoppers. High chemical resistance of the housing is ensured by the use of impact-resistant plastic powder coating.

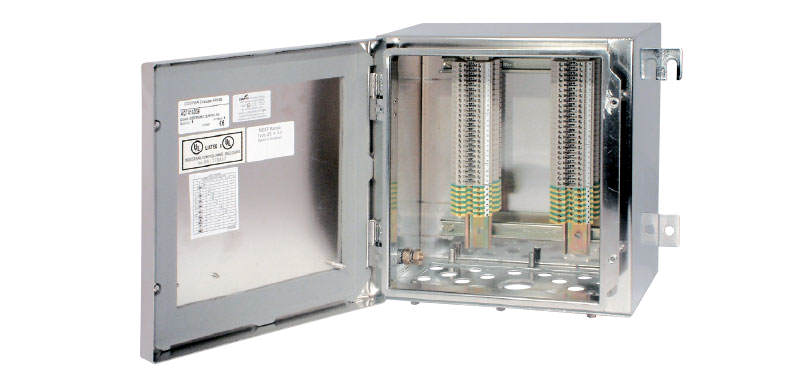

Ex-e/Ex-i Terminal Enclosures

The explosion-protected terminal enclosures made of stainless steel (AISI 316 L) with ground surfaces was developed for instrumentation and control installations using the Ex-e and Ex-i technologies. They act as a link between the main cable to the control room and the branch cables into the field. In addition to this, they may also be used for the direct connection of actuators and sensors. Here the metal cable glands also allow electromagnetically compatible connection methods.

N-TB Ex-e/Ex-i Terminal Enclosures

The N-TB enclosure has been specifically designed for installation in locations with aggressively hostile environmental conditions. These include such locations as petrochemical hazardous areas, pharmaceutical, food process and utility applications.

Ex-Cell Ex-e/Ex-i Terminal Enclosures

The N-TB enclosure has been specifically designed for installation in locations with aggressively hostile environmental conditions. These include such locations as petrochemical hazardous areas, pharmaceutical, food process and utility applications.

S-TB Ex-e Terminal Enclosures

The ST-B range is an “ATEX certified” terminal box solution available in various options of materials and finishes fully compliant with the impact, thermal and ingress requirements of EN 60079-0 ff. and EN 6124-0 ff. and is available in a comprehensive range of 12 different sizes. With for the possibilities many configuration for a multitude of applications. Using the highest quality materials, unique design benefits and precision manufacturing the S-TB range is the benchmark in heavy-duty gauge enclosures of its class. ST-B has unique wrap-round lid cover design that wraps around the body of the enclosures eliminate ingress of both liquids and dusts such as sand.

Ex-Intermediate Motor Terminal Boxes

The CEAG connection and junction boxes are used in Zones 1, 2, 21 and 22 as junction boxes for the connection of pumps, heating, motordrives etc. in hazardous explosion endangered areas.

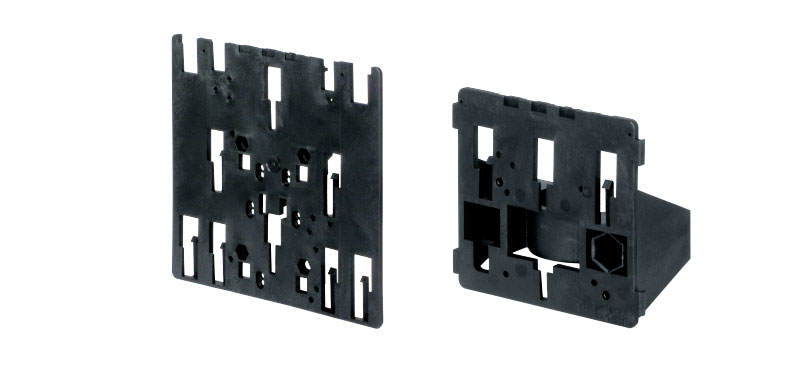

Fixing Materials and Accessories

The CEAG mounting plates are the innovative answer to the customer requested ability for mounting apparatus without having to use tools. In close cooperation with our customers, this intelligent and innovative solution for the mounting of a variety of terminal boxes and appliances onto trellis, piping and walls was developed. The clip-on mounting system in connection with the CEAG explosion-protected distribution, plugs and sockets and terminal boxes renders a decisive cost reduction.