Line heater | ATEX gas / dust zones | FP-MLH type

The FP-MLH electric line heater for gas and liquid media is very compact and requires little installation space. It is also ATEX-certified for operation in Ex-zones. The line heater’s vessel is made of mild steel or stainless steel, depending on the ordered version. The heating elements’ casing can be made of Incoloy 825/800, stainless steel, or mild steel. The electrical components are sealed in a flameproof aluminium alloy housing (which can optionally be made of stainless steel or mild steel). The housing features two cable glands, M20 and M25. The line heater can be powered with single-phase AC power (220-254 V) or three-phase AC power (380-440 V).

We will answer questions about: offer, technical specification, delivery, assembly.

A compact electric line heater for gas and liquid media (and ATEX-certified for Zone 1, 2, 21, and 22). The product is based on RFA electric immersion heater. The line heater can be powered with single-phase AC power (220-254 V) or three-phase AC power (380-440 V).

The line heater’s vessel is made of mild steel or stainless steel, depending on the ordered version. The vessel is designed for a maximum operating pressure of 10 barg (145 psig). The heating elements are encased with sheaths of corrosion-resistant Incoloy 825/800 and can be ordered in stainless steel or mild steel sheaths. The electrical equipment housing is made of an aluminium alloy (and can be ordered made of stainless steel or mild steel) and features two plugged cable glands (M20 and M25).

The heating element of the line heater is a first-quality NiCr (80/20) resistance wire. The resistance wire is secured inside the sheath filled with magnesium alloy powder which provides electrical insulation and an extremely good heat transfer coefficient.

- Ex-proof design

- Rated power: 1 kW to 12 kW (varies with the model)

- Power supply system: single-phase AC (220 to 254 V) or three-phase AC (380 to 440 V)

- Electrical wiring access: two plugged cable glands (M20 and M25)

- Mechanical installation: bolted to the substrate in horizontal or vertical orientation

- Electrical enclosure material(s): die-cast aluminium or stainless steel

- Gas/liquid vessel material(s): stainless steel or mild steel

- Heating element casing material(s): Incoloy 825/800, stainless steel, or mild steel

- Ambient temperature range: -40°C to +40°C or -60°C to +60°C (varies with the model)

- Gas/liquid vessel MOP: 10 barg (145 psig)

- Heated medium inlet/outlet connections: 1″ BSP/NPT (or 1 1/2″ on request)

- A large selection of monitoring sensors

- High-precision manufacturing

- Compact and ergonomic

- Rated power: 1 kW to 12 kW (varies with the model)

- Power supply system: single-phase AC (220 to 254 V) or three-phase AC (380 to 440 V)

- Electrical wiring access: two plugged cable glands (M20 and M25)

- Wash basins

- Industrial cleaning equipment

- DHW storage tanks

- Water cooling pre-start systems

- Engines / motors

- Engine oil pan heating

- Gas compressor lube oil tanks

- Diesel fuel tanks

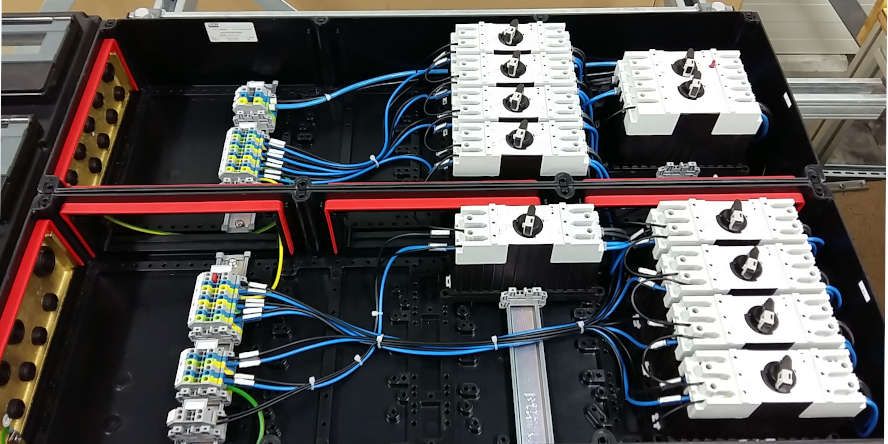

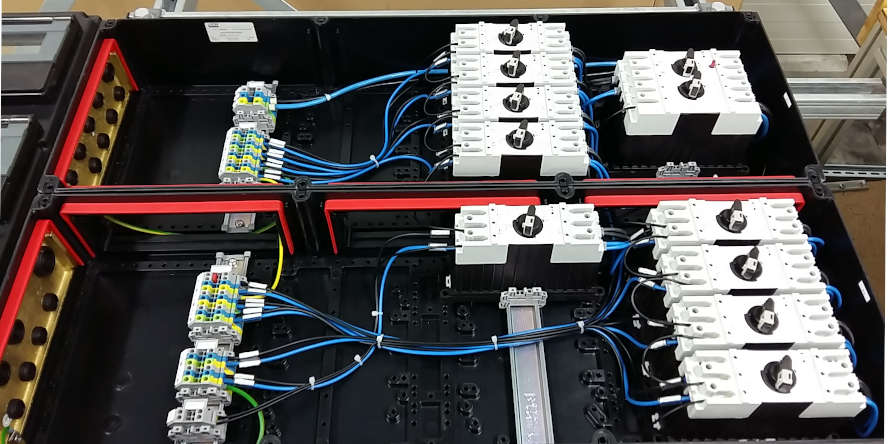

- Battery gang cabinets

- ATEX II 2 G Ex d IIC T4 do T6 Gb Strefa 1 i 2 EN 60079-0, EN 60079-1, EN 60079-7, EN 60079-31 CU TR (EAC)

- ATEX / IECEx, CSA

- Inmetro

- KGS

- CNEx

- CCOE