Process media heaters

We provide services in dimensioning calculation and selection of process media heaters for industrial cabinets and enclosures intended for operation in Ex-zones (classified as Zone 1, 2, and 21, 22). The process media heaters are installed in processing equipment units or pipelines with threaded or flanged ports. The heaters can be used in pressurized and non-pressurized processing systems.

We will answer questions about: offer, technical specification, delivery, assembly.

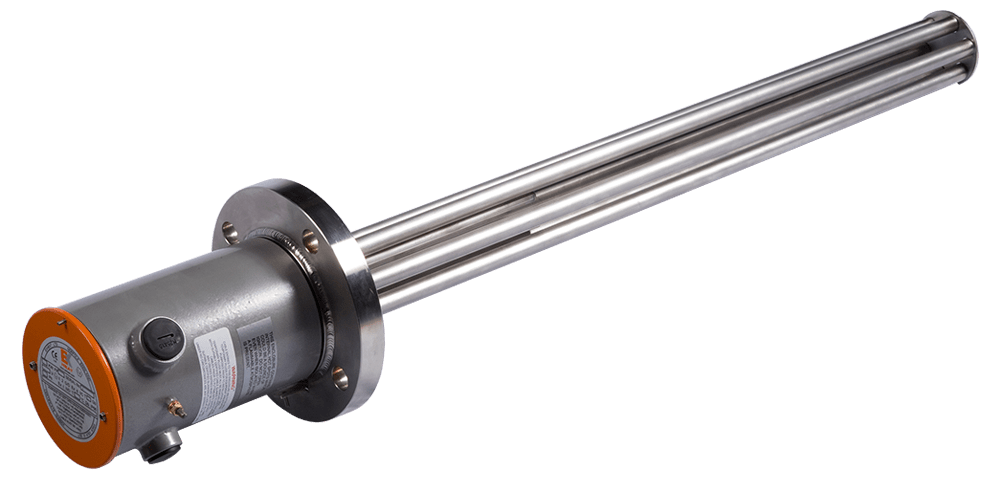

Immersion heater | ATEX gas zones | FP type

The FP immersion heaters in flameproof enclosures. The devices are ATEX, IECEx, CSA, CU TR, KGS, CNEx, CCOE, and Inmetro certified. The heaters are intended for heating process media in piping systems and equipment units operated in explosive gas or dust atmospheres. The heaters can be optionally provided with ATEX-certified thermostats. The heaters are intended for vertical installation and horizontal installation orientation versions are available on request.

Immersion heater | ATEX gas / dust zones | FP-C type

The FP-C immersion heater with a flameproof enclosure and replaceable heating element. The devices are ATEX, IECEx, CSA, CU TR, KGS, CNEx, CCOE, and Inmetro certified. The products are intended for heating of process media. The heaters can be installed in pipelines or equipment units operated in Ex-zones. The heaters can be optionally provided with ATEX-certified thermostat controls. The heaters are intended for vertical installation and horizontal installation orientation versions are available on request.

Cartridge immersion heater | ATEX gas zones | FP-CA type

The FP-CA cartridge immersion heater with a flameproof enclosure and replaceable heating element. The devices are ATEX, IECEx, CSA, CU TR, KGS, CNEx, CCOE, and Inmetro certified. These heaters are intended for heating of oil and similar chemicals which require a low heat density. The heaters are applied in processing equipment and piping operated in explosive gas or dust atmospheres. The heaters can be optionally provided with ATEX-certified thermostat controls.

Plunger Heater | ATEX – gas / dust zone | RFA type

A plunger heater type RFA in a flame-proof enclosure. This device is ATEX, IECEx, CSA, CU TR, KGS, CNEx, CCOE, and Inmetro certified. Heaters of this type are designed for heating up process media. They are used in process tanks, including pressure tanks and other equipment located in gas and dust explosion hazard zones. The heater can be installed vertically or horizontally (optional), using a threaded or flanged connection.

Immersion heater | ATEX gas / dust zones | RFA-C type

The RFA-C immersion heaters in flameproof enclosures. The devices are ATEX and CU TR certified. The products are intended for heating of process media. They can be installed in processing tanks and other equipment operated in explosive gas or dust atmospheres. The heaters are intended for vertical installation and horizontal installation orientation versions are available on request. The heater can be installed with a threaded end or a flanged connection port.

Cartridge immersion heater | ATEX gas / dust zones | RFA-CA type

The RFA-CA cartridge immersion heaters in flameproof enclosures. The devices are ATEX and CU TR certified. The products are intended for heating of process media, mainly oils and similar chemicals. The heater can be opened for inspection without breaching the seal and emptying the processing system of the heated medium. The heaters can be installed in processing tanks and other equipment operated in explosive gas atmospheres. The heaters are intended for vertical installation and horizontal installation orientation versions are available on request. The heater can be installed with a threaded end or flanged connection.

Process media heaters: key features

- ATEX-compliant design

- Easy installation with threaded adapters or standard connection ports

- Maintenance-free

- Compatible with thermostat controls

- Large selection of replaceable parts available

- Stepless temperature control

- Quick installation

- First-class manufacturing quality

- High heating efficiency

The electric heaters are designed for operation in potentially explosive atmospheres (and ATEX certified for Zone 1, 2, and 21, 22). The heaters can be supplied with integrated thermostats or external, wall-mounted thermostats. As they are available in a large selection of materials, there is always an optimum electric heater for the specific operating conditions (including exposure to corrosives, acids, alkalis, and other heavy-duty conditions).

A major advantage of the electric heaters is their quick and easy installation in processing equipment and pipelines with the use of threaded adapters or standard connection ports.