Cartridge immersion heater | ATEX gas / dust zones | RFA-CA type

The RFA-CA cartridge immersion heaters in flameproof enclosures. The devices are ATEX and CU TR certified. The products are intended for heating of process media, mainly oils and similar chemicals. The heater can be opened for inspection without breaching the seal and emptying the processing system of the heated medium. The heaters can be installed in processing tanks and other equipment operated in explosive gas atmospheres. The heaters are intended for vertical installation and horizontal installation orientation versions are available on request. The heater can be installed with a threaded end or flanged connection.

We will answer questions about: offer, technical specification, delivery, assembly.

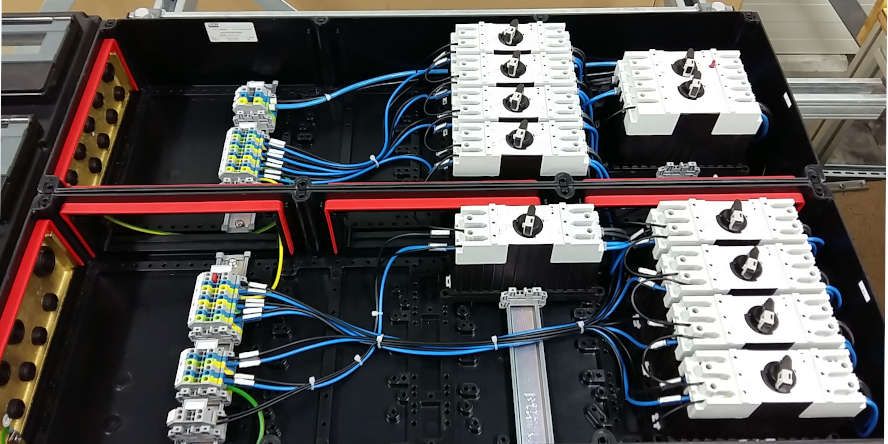

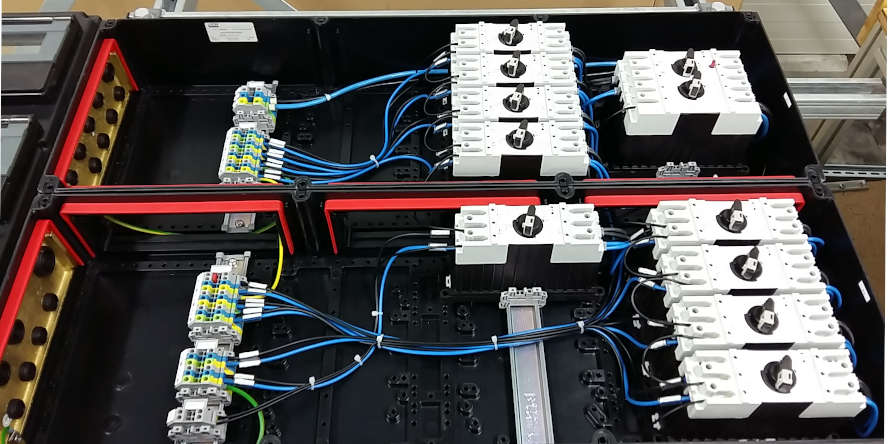

The RFA-CA electric cartridge immersion heater is ATEX-certified for use in Zone 1 and 2. The standard versions of the product can be supplied with any electrical power source up to 690 V (600 V CSA). Each heater is provided with a heavy-duty terminal box for easy and secure wiring. The product’s design ensures fast installation in processing pipelines (with a threaded end or a connection flange).

The heater is designed for long, heavy-duty operation (with a rating of IP66 or IP67). The robust enclosure is made from epoxy-coated aluminium. This series of heaters is intended for heating of various oil types in processing tanks and other equipment units. The heaters are compatible with single or three-phase alternating current or direct current supply systems. The enclosure design allows removal and inspection of the heating element without breaching the seal and emptying of the whole processing system.

The heating element is a high-quality, NiCr (80/20) resistance conductor. It is installed in a sheath of stainless steel grade 316L filled with magnesium oxide powder which provides electrical insulation and an extremely good heat transfer coefficient. The seal is provided by hard brazing or fusion welding, depending on the process medium and processing parameters specified.

The product is supplied with one 20 mm cable gland and one 25 mm cable gland. The standard version features overtemperature protection and external and internal earthing connections.

The permitted ambient operating temperature of the heaters ranges from -40˚C to +40˚C.

- ATEX: certified for operation in potentially explosive gas or dust atmospheres (Zone 1 and 2)

- Installation: threaded end or flanged connection

- Supply voltage: 690 V maximum

- Rated power: 8 kW maximum

- Casing material(s): powder-coated aluminium

- Heating element: high-quality NiCr resistance wire in carbon steel or stainless steel grade 316L sheath, filled with magnesium oxide powder

- Control: Ex-proof thermostat control (optional)

- Ingress protection: IP66 or IP67

- Ambient temperature: -40˚C to +40˚C

- Optional protection features: thermostat control

- Enclosure finished with epoxy coating

- Installation orientation version for vertical pipelines

- Casing material(s): stainless steel or carbon steel

- Optionally available with temperature measurement sensors

- Processing tanks

- Emergency decontamination showers

- Engine oil pans

- Pressure vessels

- Chemical mixers

- CW heater compressor

- Lube oil compressor

- Water/glycol compressor

- Diesl fuel tanks

- GLNG

- High-pressure cleaners

- Improvement of viscous medium flow

- Anti-freeze protection for water and other chemicals

- ATEX

II 2 G

II 2 G - Ex d IIC T3 to T6 Gb Strefa 1 i 2

- CU TR (EAC)