Industrial lighting design

We specialise in industrial lighting with a particular focus on facilities with: dusty, corrosive atmospheres, explosion and fire hazards or other specific conditions that require extensive experience in design, component selection and installation. We pay equal attention to service costs and energy consumption.

General lights

- LED

- standard or EX design

- operation as emergency lighting (optional)

- compliant with standards and CNBOP

- robust industrial design

- various manufacturers (selection to suit working conditions)

Emergency lights

- built-in or central battery

- standard or EX design

- compliant with standards and CNBOP

- industrial versions

- various manufacturers (selection to suit working conditions)

Evacuation lighting

- designed as part of emergency lighting

- compliant with standards and CNBOP

- standard or EX design

- industrial versions

- various manufacturers (selection to suit working conditions)

Back-up lighting

- designed as part of emergency lighting or back-up lighting (no normative requirements)

- compliant with standards and CNBOP

- standard or EX design

- industrial versions

- various manufacturers (selection to suit working conditions)

We specialize in

Industrial facilities

- chemicals and petrochemicals

- energetics

- wood industry

- food industry

- processing

Fire hazard

- we take fire regulations into account

- we avoid collision with fixed fire-extinguishing appliances

- we select electrical fittings and power supply suitable to fire risks

Explosion hazard

- we take ATEX requirements into account

- we designate explosion risk zones

- we use equipment for explosion risk zones

Corrosive environment

- we select luminaires and other installation components to suit the working environment

- we take into account gas and vapour release locations

- we take into consideration danger zones

WE OPERATE ON THE BASIS OF THE C-P-D METHODOLOGY

Concept with variants

We often present a concept with variants based on different components before starting design work…

Project

We carry out projects for both newly-built and upgraded facilities. At this stage…

Development

Depending on your needs, our activities may include not only the concept and design, but also the physical execution …

Realised lighting projects

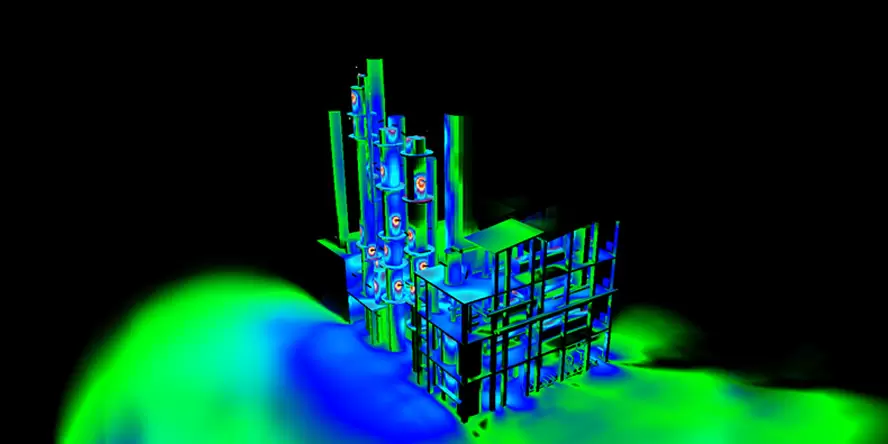

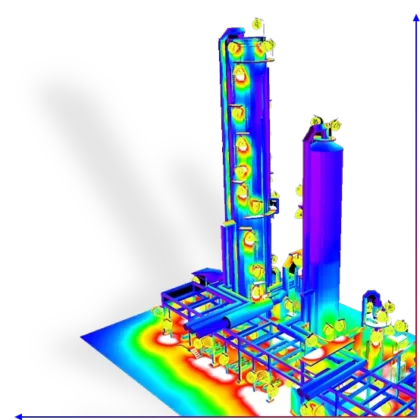

Ethanol plant

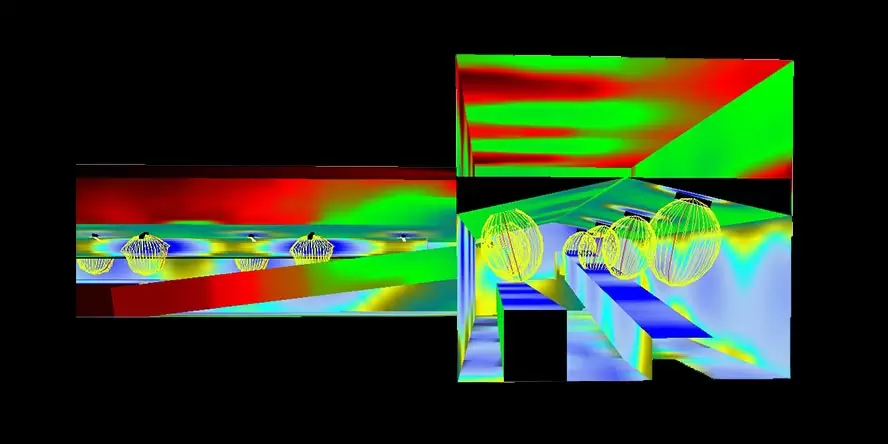

Energy sector – skewed bridge

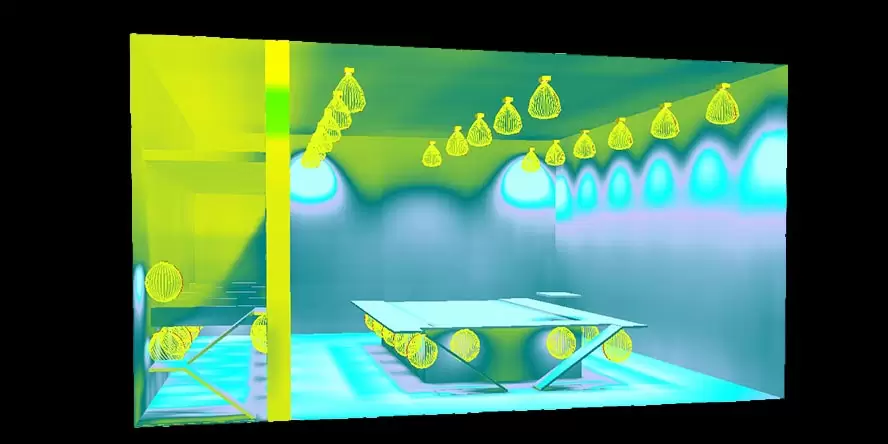

Production building

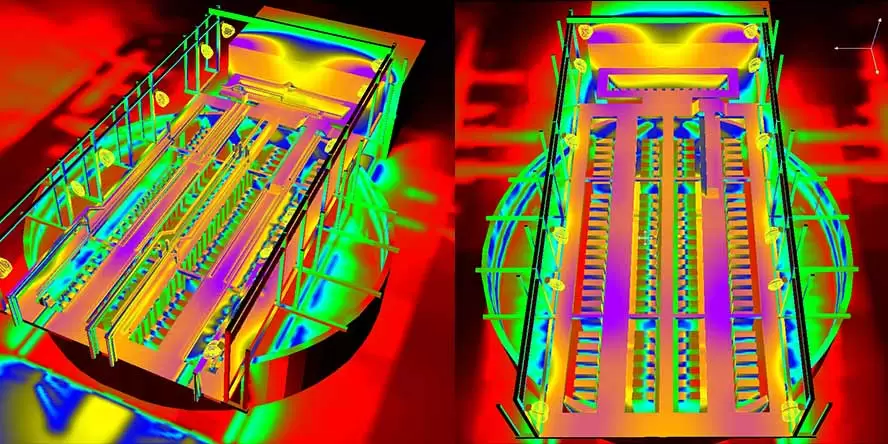

Complicated social facilities

Personnel facilities

Staircase in a production facility

For which facilities do we design lighting?

Interior lighting

- industrial plants with production areas

- storage and handling halls

- technical and social buildings with office space

- spray booths

- technical containers and analysis laboratories

- food processing plants

- waste treatment and processing plants

Area lighting

- process and production facilities

- tanks and valve areas

- pumping and compressor stations

- vehicle and rail terminals including VRU installation

- internal roads and maneuvering areas

- offshore and onshore oil platforms

Project contributions

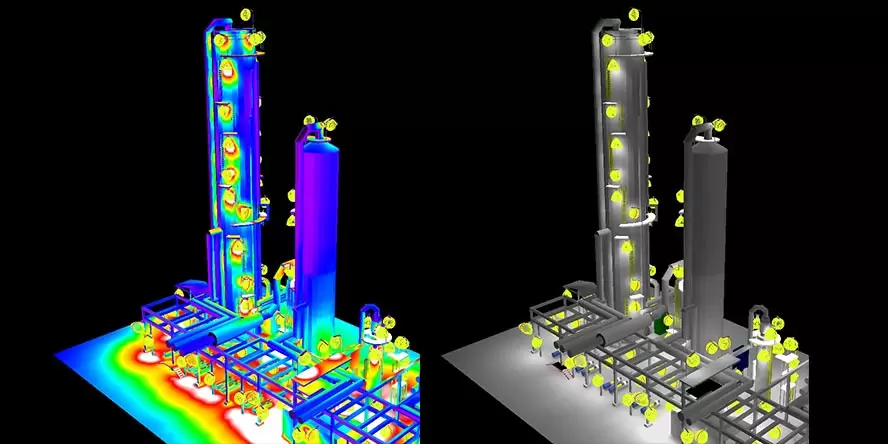

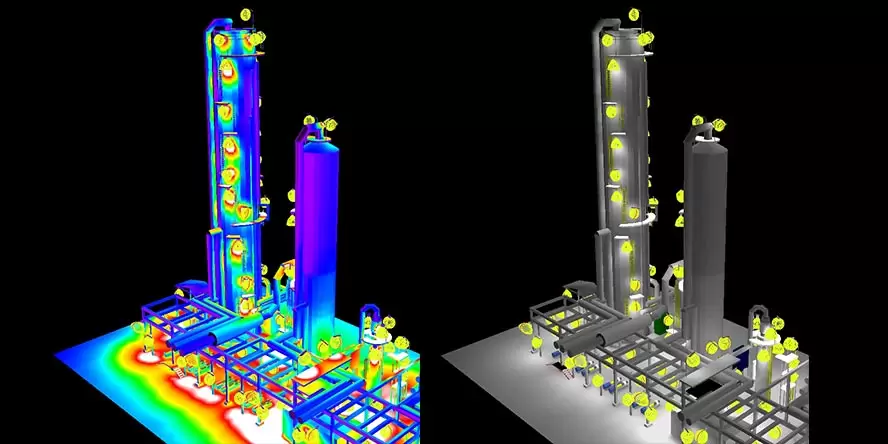

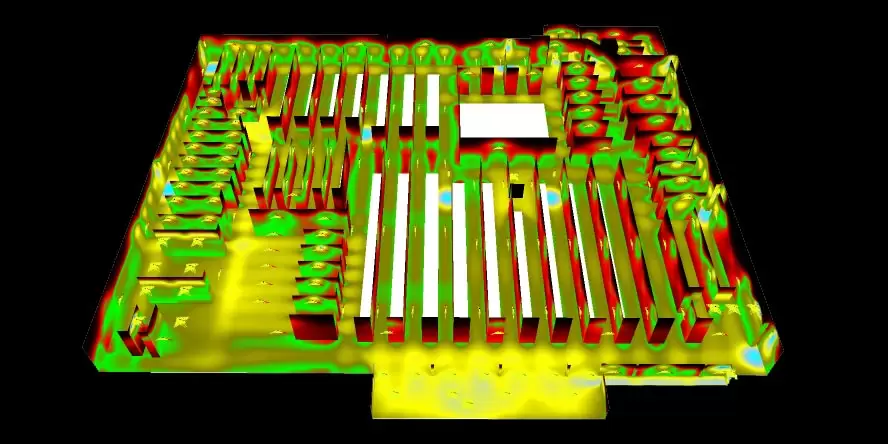

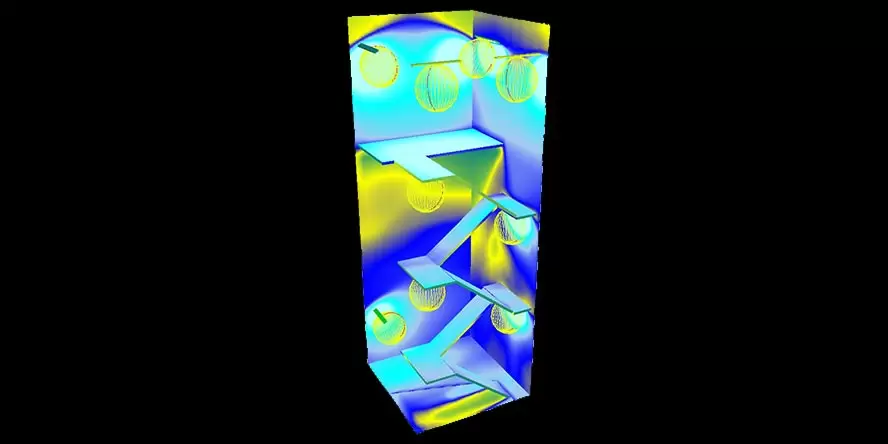

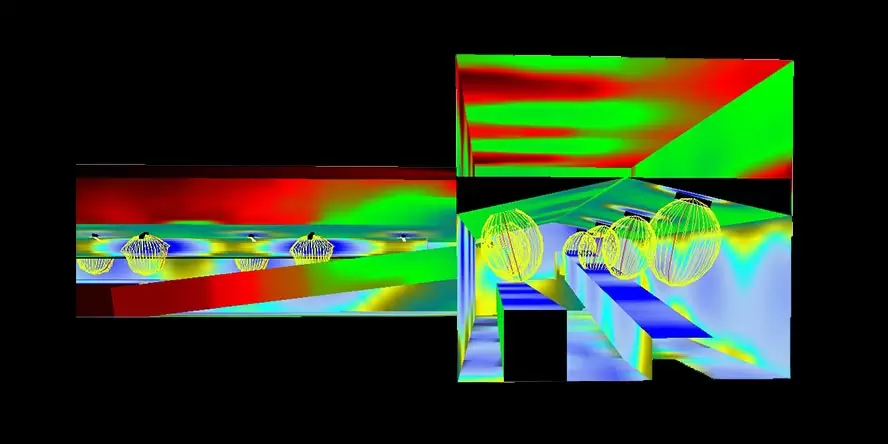

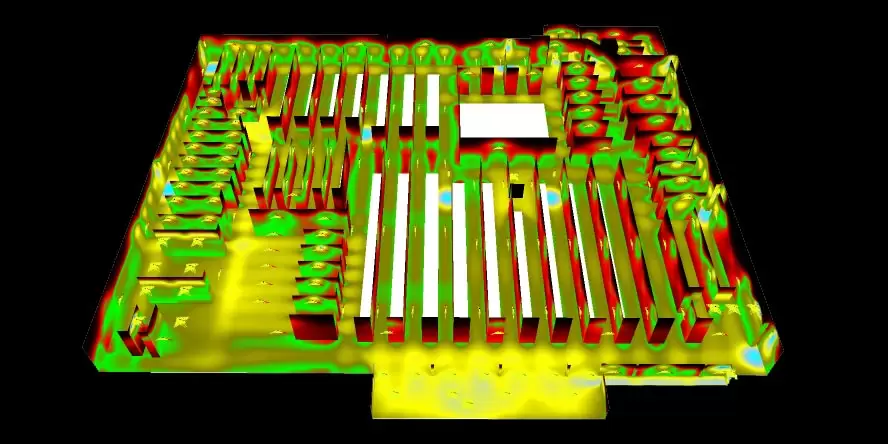

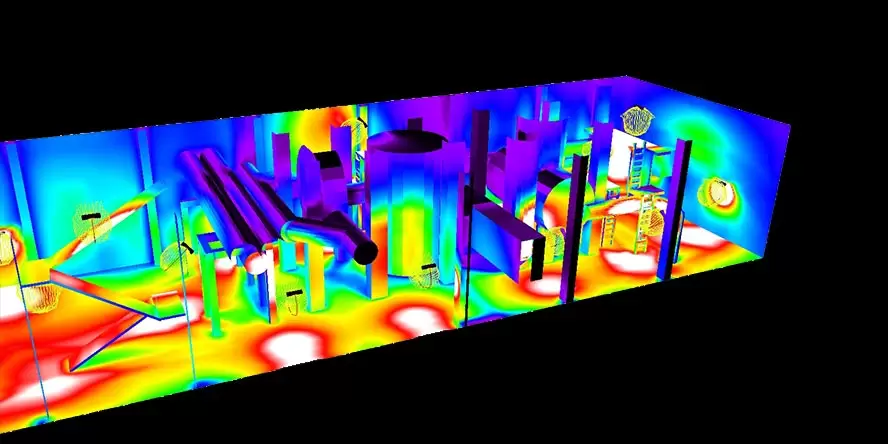

For the areas and facilities listed, we also provide design input based on electrical parameter calculations and CAD and 3D software support in the form of schematics, plant and equipment distribution plans and a 3D model.

Light scenes

On request, we develop lighting scenes for specific customer requirements with possible consideration of environmental and atmospheric conditions dependent on changing emergency and weather conditions.

Why customers choose us

- we specialise in industrial facilities – the complexity of industrial spaces, combined with specific hazards and regulations, means that lighting design requires a great deal of experience

- the project is preceded by a concept with recommendations – this approach will allow you to make an informed decision taking into account all the pros and cons

- the advantages and limitations of the proposed solutions – there are no solutions without disadvantages, but if you know them you will be able to choose the optimal solution for your case

- we work according to the Concept-Design-Delivery methodology – such an approach ensures comprehensive implementation of a given task, thus minimising the risk of errors that may arise between the designer and the contractor

- we have experience in difficult industries – industrial facilities with difficult working conditions and process risks such as explosion, fire or leakage require a specific approach

Concept with variants

We often present a concept with variants based on different components before starting design work… In doing so, we indicate our recommendations, giving specific advantages and limitations of each solution. This approach gives you a great deal of freedom to choose a concept tailored to your technical and cost expectations.

Lighting design

We carry out projects for both newly-built and upgraded facilities. At this stage, we try to secure the contractor in every aspect by also informing him of the risks he may encounter during commissioning and subsequent operation, as well as providing an estimate of the costs of servicing and future eclectic energy consumption.

Development

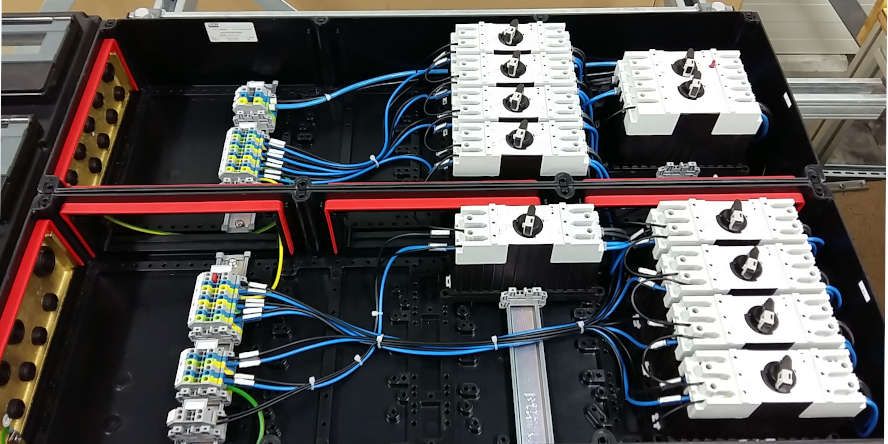

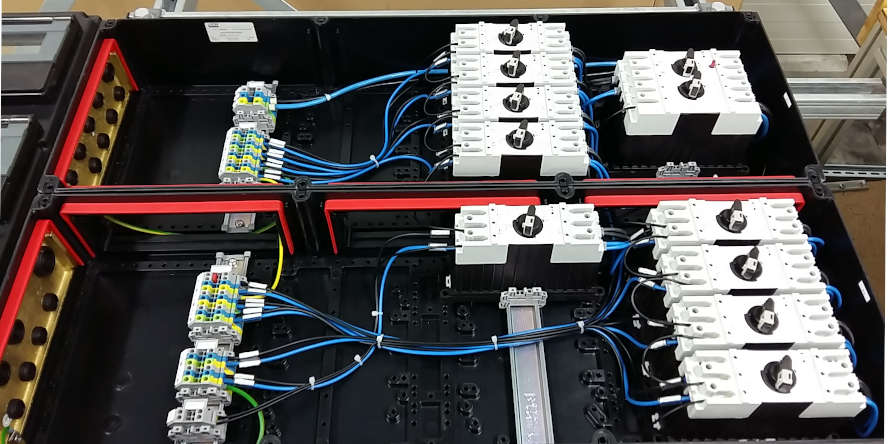

Depending on your needs, our activities may include not only the concept and design, but also the physical execution of the lighting installation and the necessary electrical installations or central batteries. The main advantage of having the entire task carried out by one company is that errors are kept to a minimum. In other words, in the K-P-R model we take full responsibility for the success of the task. Thus, the responsibility for possible errors is not diluted among several companies, which often ends up in blame-shifting.

Who we work for

Most of the lighting and electrical installation projects we carry out in cooperation with clients, design offices and contractors are for areas with a high risk of explosion, fire or leakage of hazardous substances. Completed facilities for state-owned companies such as PKN Orlen, Azoty Group, Anwil or private investors such as BIOAGRA were constructed in accordance with the investors’ guidelines and applicable standards.

WE MET THE CHALLENGES OF THE MOST DEMANDING

Lighting for industry

Design is only part of our capabilities

As you may already know, we operate on the basis of the C-P-D methodology. This means that we start our cooperation with a concept that includes several possible options. At this stage, we want to give you the arguments ‘for’ and ‘against’ so that your decision takes into account technical, legal as well as economic issues. You can also count on our recommendation to help you make the right decision. Find out what else we can do for you.

What the lighting design includes

- the concept of the proposed solution

- calculation of light parameters for room surfaces and external areas

- simulations of primary, security, emergency / backup and evacuation lighting in relation to environmental conditions,

- 2D and 3D visualisations of lighting intensity and rendering of light distribution

- 2D or 3D CAD layout plans for use with external programs such as REVIT, MacroStation

- a summary of the equipment, luminaires used in the project, including connecting components for power supply installations and fastenings to structural elements

- calculations for the cable installation including parameters for the power supply of safety and fire protection equipment.

- block diagrams of the installation and detailed circuit diagrams of the switchboards for the supply of luminaires and peripherals

- lists of signals to and from the automation sector for detection, control and process visualisation systems

electrical and fire protection approval of the documentation.