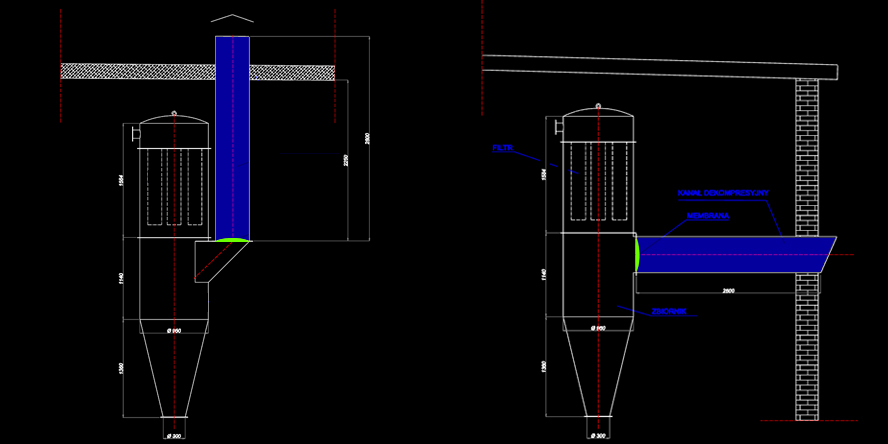

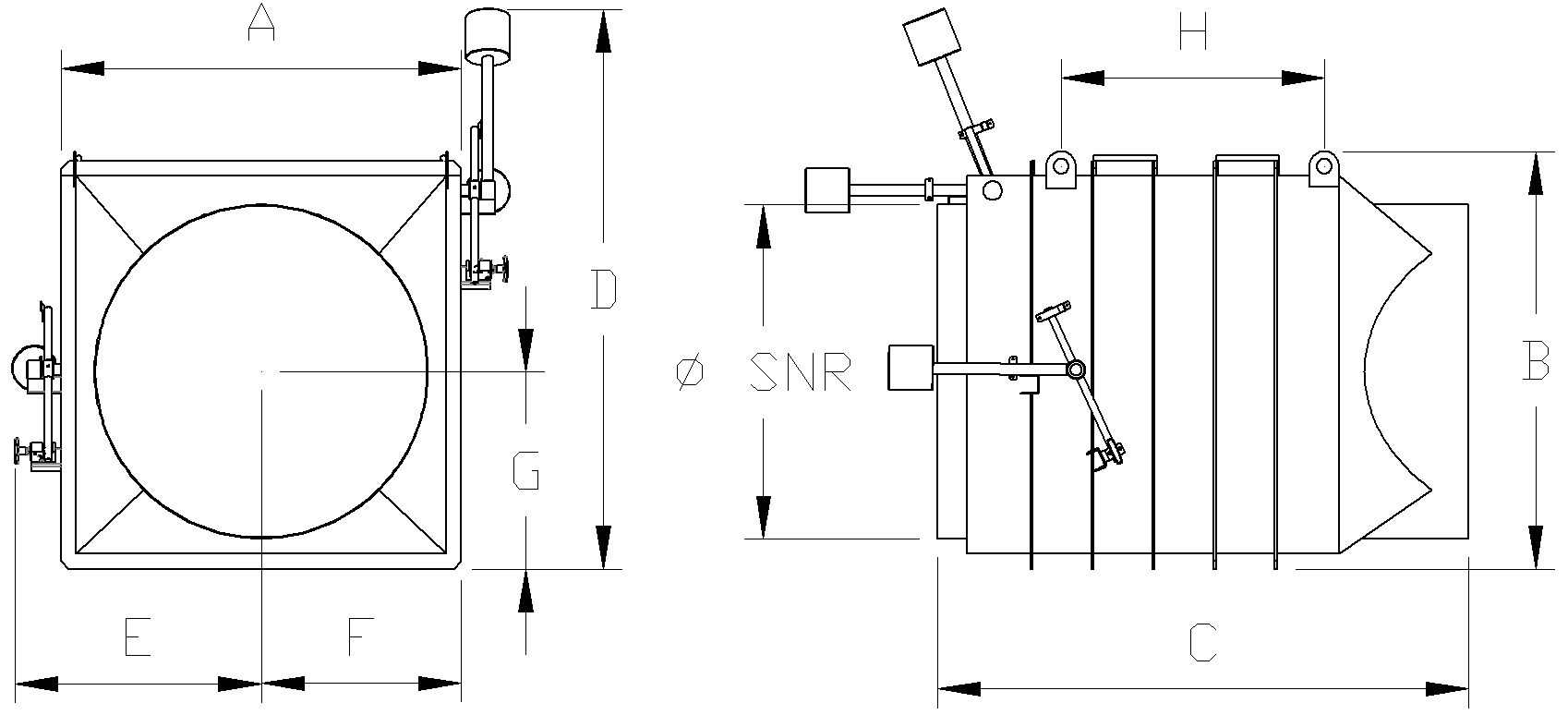

SNR non-return damper

The SNR non-return damper is a simple and cost-effective solution for isolation of an explosion origin by closing the ductwork and preventing further propagation of explosion to the remainder of the protected installation.

- Application: organic dust; metallic dust

- System internal ATEX zone: Zone 20, 21 and 22

- System external ATEX zone: Zone 21, 22

- Max. reduced explosion isolation pressure, Pred: 0.5 bar

- Max. Kst: 400 bar×m/s

- Max. operating pressure: 50,000 Pa

- Maximum air flow velocity: 30 m/s

- Min. installation distance from potential explosion origin:

- 1 m for dust with Kst < 200 bar m/s; 1 m for dust with Kst; 200 bar m/s;

- Max. installation distance from potential explosion origin: 2-3 m

- Material(s):

- Carbon steel, gauge 30/10 or 40/10

- AISI 304 grade stainless steel

- System pressure drop

- ≤ Ø 400: 10 mm H2O

- ≤ Ø 700: 16 mm H20

Optional accessories available on request:

- Open damper lock: engaged following an explosion trigger;

- Closed damper position sensor;

- Damper lock capacitative sensor: triggered by the flow of product.

The non-return dampers require a horizontal orientation and installation in line with a straight ductwork run. The ductwork diameter must be equal to that of both non-return damper ports.

| MODEL | MAX KST | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|---|

| SNR 160 | CLASS 3 - 400 [BAR M/S] | 360 | 340 | 550 | 340 | 300 | 180 | 170 | - |

| SNR 180 | CLASS 3 - 400 [BAR M/S] | 360 | 340 | 550 | 340 | 300 | 180 | 170 | - |

| SNR 200 | CLASS 3 - 400 [BAR M/S] | 360 | 340 | 550 | 340 | 300 | 180 | 170 | - |

| SNR 250 | CLASS 3 - 400 [BAR M/S] | 410 | 390 | 600 | 390 | 325 | 205 | 195 | - |

| SNR 300 | CLASS 3 - 400 [BAR M/S] | 460 | 440 | 670 | 600 | 350 | 230 | 220 | - |

| SNR 350 | CLASS 3 - 400 [BAR M/S] | 510 | 490 | 720 | 650 | 375 | 255 | 245 | - |

| SNR 400 | CLASS 3 - 400 [BAR M/S] | 560 | 590 | 770 | 750 | 400 | 280 | 270 | 350 |

| SNR 450 | CLASS 3 - 400 [BAR M/S] | 610 | 640 | 820 | 845 | 425 | 305 | 295 | 400 |

| SNR 500 | CLASS 3 - 400 [BAR M/S] | 660 | 690 | 870 | 985 | 450 | 330 | 320 | 460 |

| SNR 550 | CLASS 3 - 400 [BAR M/S] | 710 | 740 | 920 | 950 | 475 | 355 | 345 | 500 |

| SNR 600 | CLASS 3 - 400 [BAR M/S] | 760 | 790 | 970 | 1045 | 500 | 380 | 370 | 550 |

| SNR 650 | CLASS 3 - 400 [BAR M/S] | 810 | 840 | 1020 | 1145 | 525 | 405 | 395 | 605 |

| SNR 700 | CLASS 3 - 400 [BAR M/S] | 860 | 890 | 1070 | 1195 | 550 | 430 | 420 | 650 |