Flameless relief

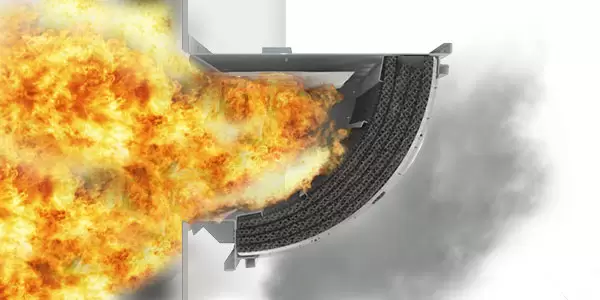

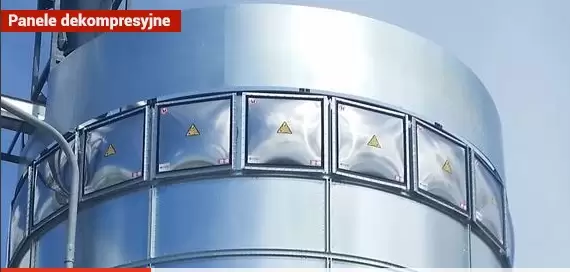

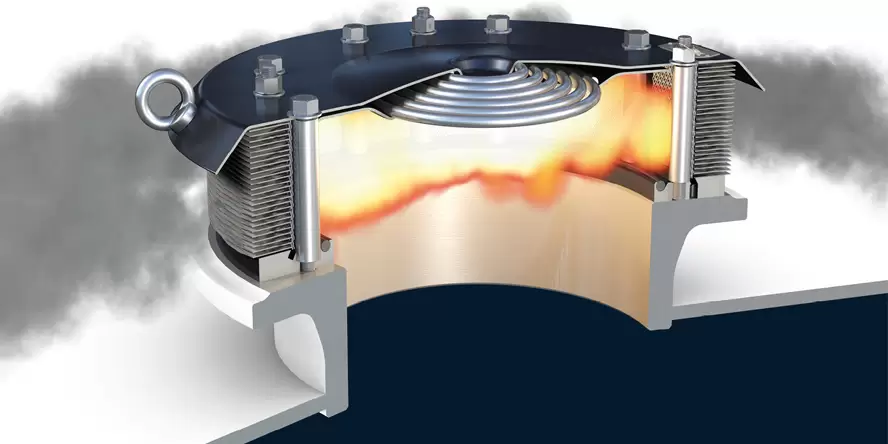

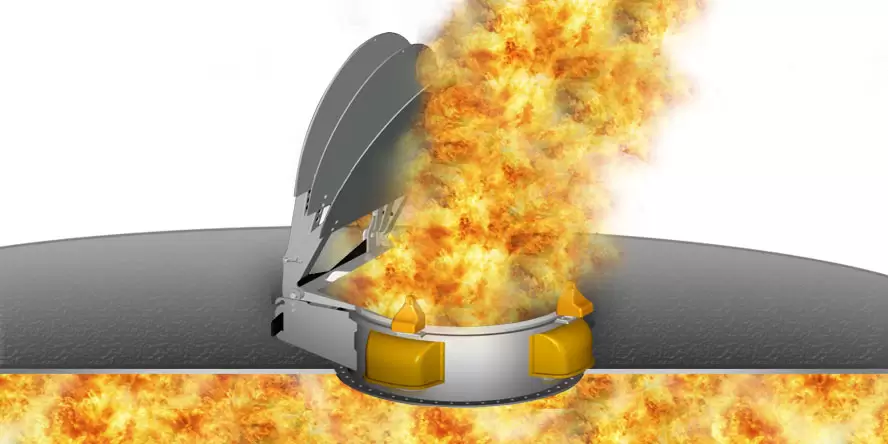

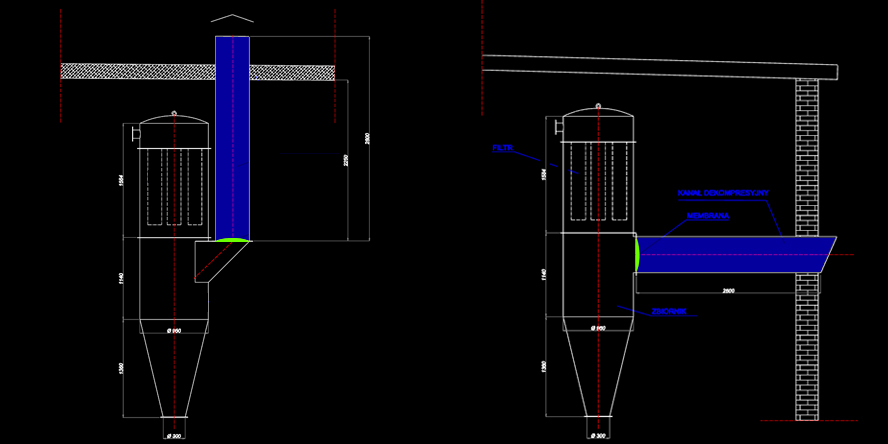

A flameless explosion venting device consists of a decompression panel and a special perforated steel enclosure. The protection system is mounted on the wall of the protected apparatus. When an explosion occurs inside, the decompression panel undergoes controlled “opening,” preventing a rise in pressure. Thanks to the use of the mentioned enclosure, the pressure is safely released into the environment. Importantly, this process does not involve the expulsion of a fireball, which is typical of traditional decompression panels. All of this ensures that this form of protection guarantees the highest level of safety, protecting both the device and the personnel, as well as other equipment that may be nearby. Unlike panels, flameless explosion venting can be used in enclosed spaces such as halls or buildings.

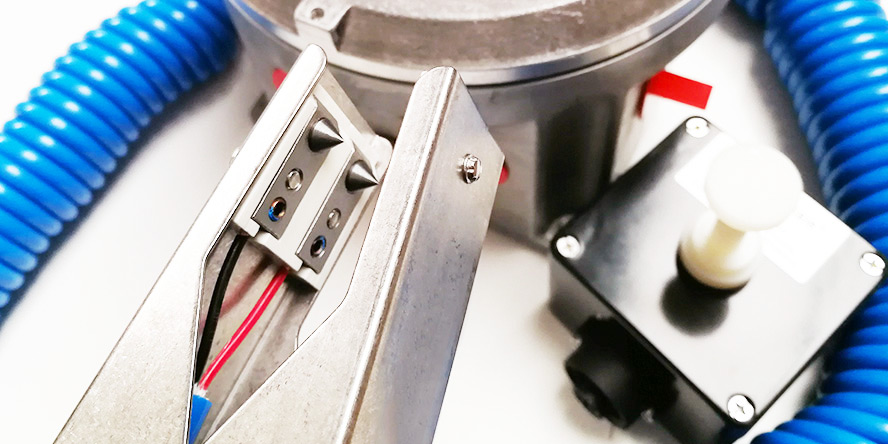

A special modification of the flameless explosion relief device is the EVN relief valve. It does not have a built-in decompression panel, so there is no need to replace it after an explosion. Instead, the valve consists of a spring that expands under the influence of the explosion and allows the pressure to escape, cooling the gases and extinguishing the flames in the process.

FLAMELESS RELIEF

Alternative safety devices for large flameless explosion relief kits

Single-use protection method for indoor and outdoor use. Flames and pressure are NOT released into the environment. Reduced risk of fire in the apparatus after an explosion.

The most affordable protection method for use outside buildings. Flames and pressure are released into the environment (danger to people and equipment). The need to demarcate a danger zone.

Reusable protection device for indoor and outdoor use. Flames and pressure are NOT released into the environment. Minimal risk of fire in the apparatus after an explosion.

Security for coal and alternative fuels. For use outside buildings. Flames and pressure are released into the environment. Minimal risk of fire in the apparatus after an explosion

Are you looking for a system without the above restrictions?

Check the explosion suppression systems

If the above systems have too many limitations, and you are looking for the most advanced explosion protection system, then be sure to check out explosion suppression systems. This is the solution free of the restrictions listed above. Often, this is also a perfect solution in terms of price, especially when considering the longer term use and installation costs.

See also:

Explosion isolation

The isolation complements the explosion protection system mentioned above. The purpose of the explosion isolation is to isolate the device in which the explosion occurred from the rest of the system. This eliminates the risk of pressure and fire going over onto adjacent equipment, which would lead to very dangerous secondary explosions. Why is it so dangerous? Because the fire and pressure are characterised by much higher dynamics and energy, and there are no safeguards to protect us in such a situation.

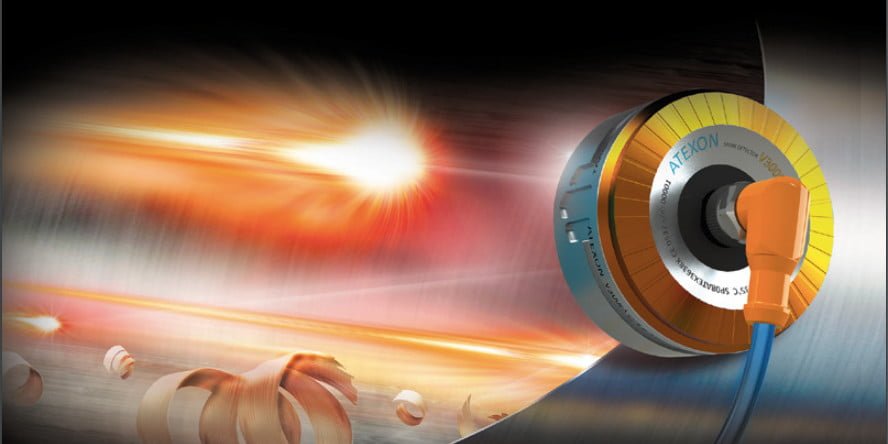

Prevention

According to the ATEX Directive, the employer, in order to protect property and the health and life of workers, should implement measures to prevent and minimise the effects of an explosion. This approach is based on the fact that although the safeguards can significantly reduce the risk of explosion, they can never provide 100% safety. We are facing a similar approach in our cars. Despite a number of preventive measures such as the ABS system, every car has crash mitigation measures which include air bags, seatbelts or structural reinforcements.

which system will be the best value for money and ensure compliance at the same time?

Flameless explosion relief – the most commonly selected systems

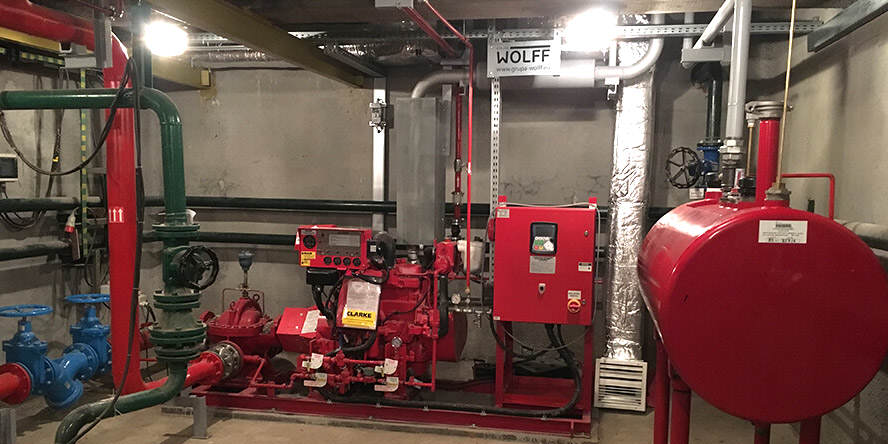

Flameless explosion vent IV8

In case of an explosion in a protected device, the IV8 flameless explosion vent brings out the cooled gases caused by the explosion. Thanks to the special design of the explosion vent device, during the release of the explosion the flame is extinguished, the pressure is significantly reduced and the gases are cooled.

EVN type explosion relief valve

The EVN type explosion relief valves are protective systems as defined in the ATEX Directive. The EVN 2.0 type explosion relief valves have been tested for performance with the following dust groups: starch, plastic, resin, toner, sugar, wood, MDF, cellulose (fibrous dust), coal, and peat.

Flameless explosion relief – other systems

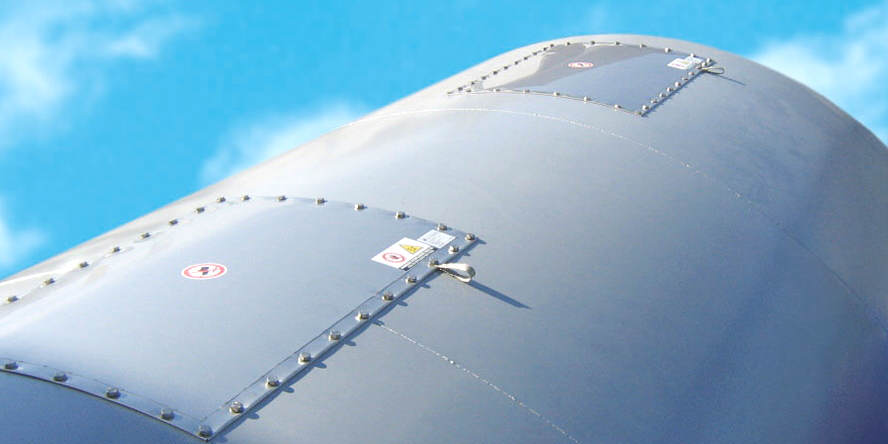

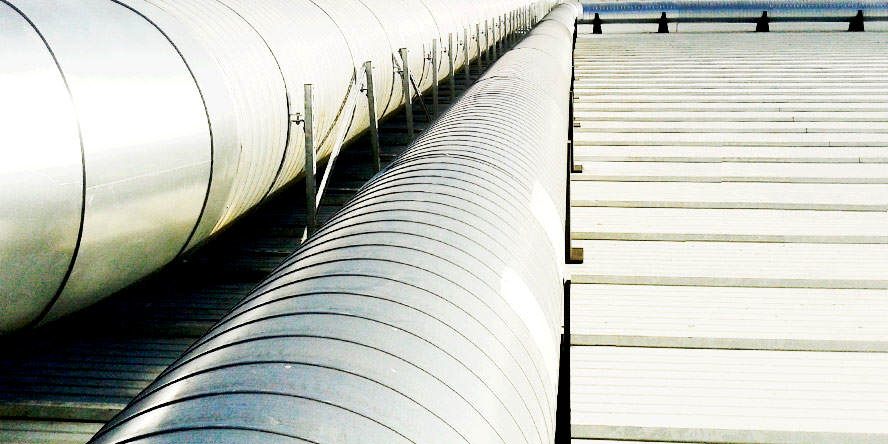

VQ flameless explosion venting system

VQ provides explosion protection to indoor equipment and machinery by flameless explosion venting with dust protection. There is no egress of clean or burned dust. The overtemperature is minimised.

You are protected by our insurance

Only those who do nothing make no mistakes. And while the quality of the work carried out is a priority for us, it is not possible to completely eliminate human error. Unforeseen production stoppages or product contamination during the installation of a system might result in considerable losses. Similarly, a mistake during the design and installation of an explosion protection system can have dire consequences. That is why our insurance policy protects both us and your establishment from unforeseen costs. We have probably the highest insurance policy on the market.

Large and fast service is important

Don’t risk costly downtime of your installation

Would you buy a car that doesn’t have a Polish service center? Or if such a service center only had three employees and had to import spare parts from abroad? Probably not. And in a similar situation, would you buy security systems for your production facility, on which the continuity of its operation depends? Would you risk an unjustified downtime and losses amounting to hundreds of thousands of zlotys? Meanwhile, some companies providing explosion-proof security systems either do not have a Polish service center or rely on just 2-3 employees. The problem can also lie in the availability of spare parts warehouses, which are often located outside of Poland. That’s why we have created the largest 24/7 service center in the industry, along with a large component warehouse.

Emergency number 24/7

+48 508 484 508

Selected countries in the world

where our customers’ production facilities are located

20 service technicians

5 fully equipped brigades

We complete formalities in accordance with local law.

We provide permissions in accordance with local law.

Work in potentially explosive areas.

Work in fire-risk areas.

Quick reaction.

We communicate in English.