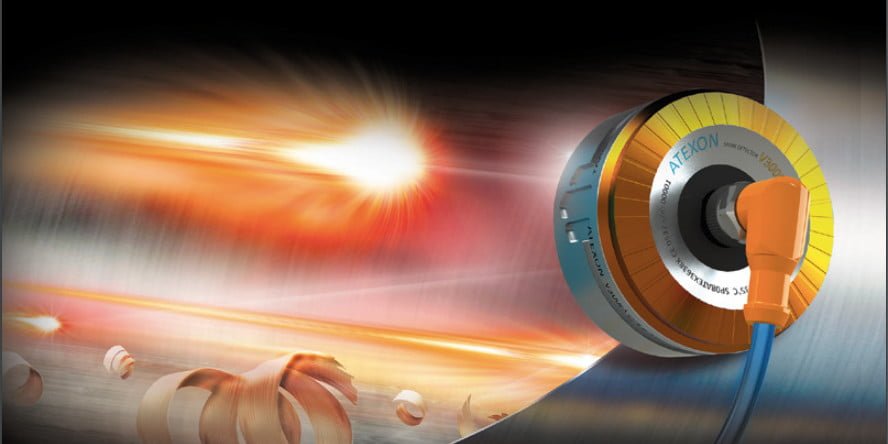

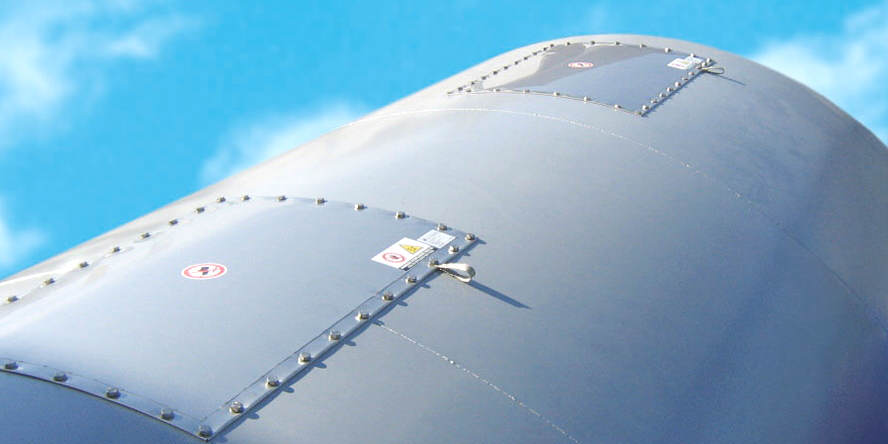

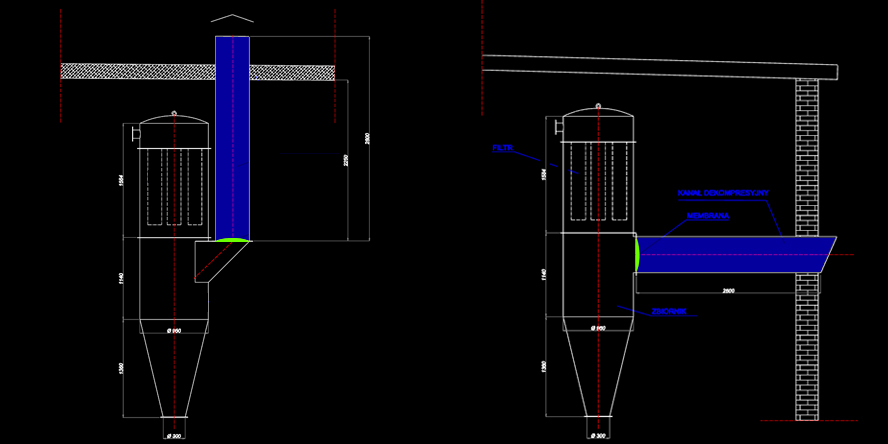

TT‑Uni‑K round explosion relief dampers

Applications

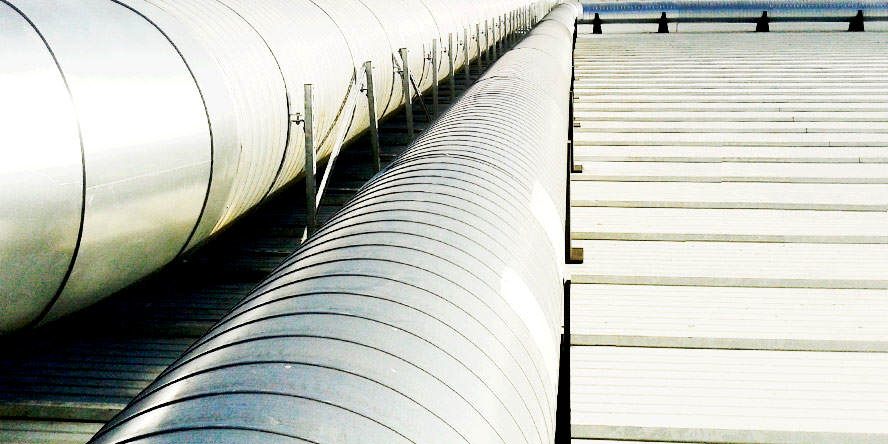

- Protection of tanks and silos against damage from explosion by controlled relief and venting of explosion products into the atmosphere;

- Self-closing following an explosion relief action (the damper isolates the flow of air).

Specifications

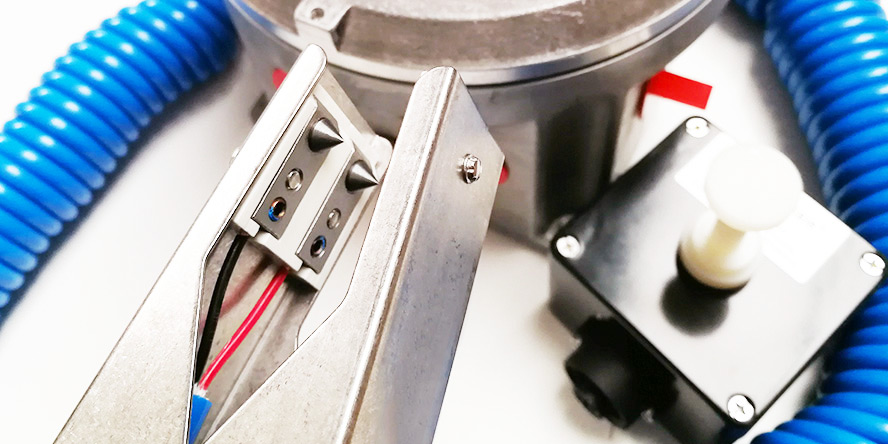

- The pressure of explosion releases the damper closure from its retaining latches, which opens the damper;

- 80% of the resulting damper recoil force is dampened by the air cushion formed between the explosion relief damper and steel deflector plates;

- The residual recoil force of the damper is further dispersed by the deflector plates and the damper is closed automatically to isolate the flow of air once the explosion products have been vented;

- The damper’s structure eliminates any transfer of explosion loads to the silo structure;

- The spring-loaded retaining latch helps set the initial opening pressure of the explosion relief damper (the standard setting is 0.1 barg);

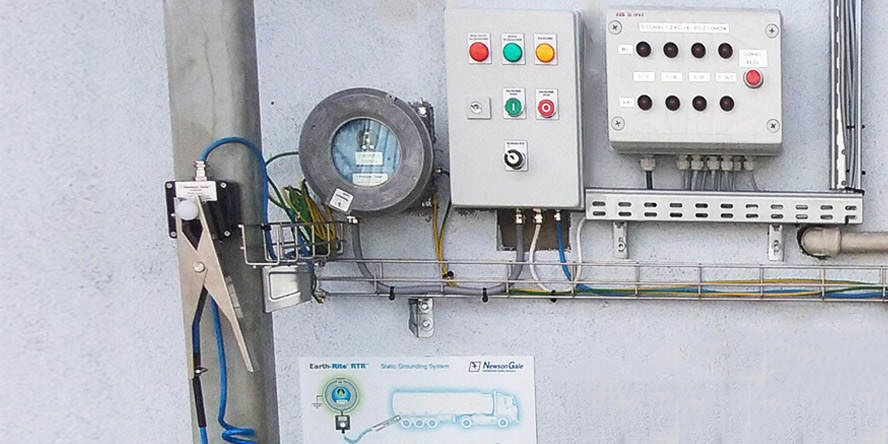

- Each opening action of the explosion relief damper can be remotely indicated by a limit switch;

- The vacuum pressure resulting inside the silo after the explosion (by quick cooling of gases) is eliminated to prevent implosive collapse of the vessel;

- The TT‑Uni‑K explosion relief dampers can optionally feature electric heaters.