ATEX training tailored for companies

Closed-type training sessions are organized specifically for a given company or organization. The flexibility of such a solution allows for better adaptation of the thematic scope, date, and place of training to the client’s requirements. Typically, between 5 and 15 people participate in the training.

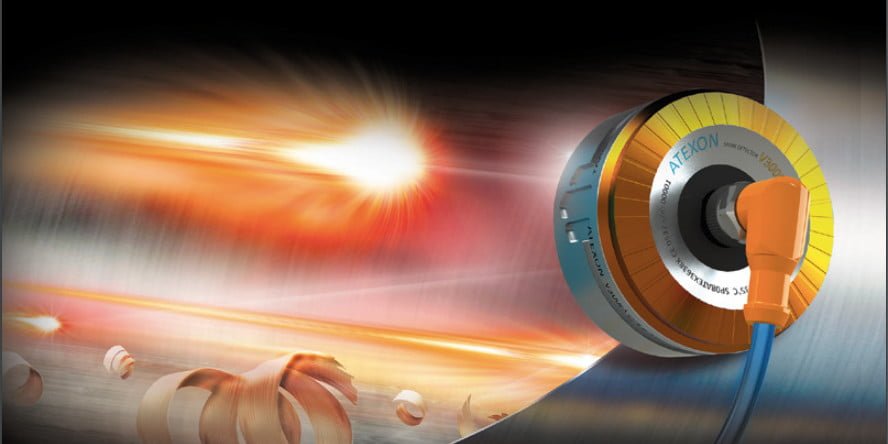

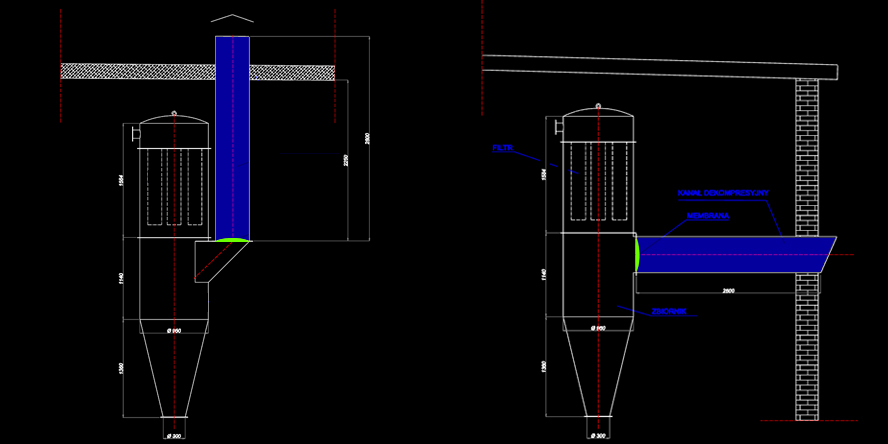

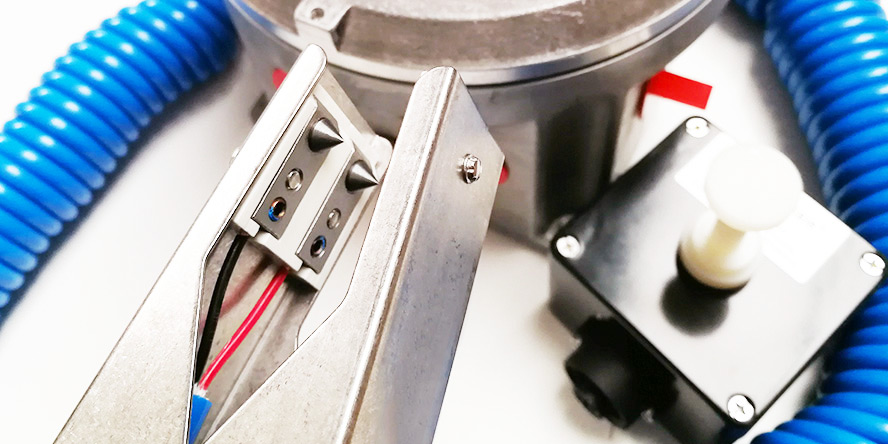

During ATEX training, you will learn about, among other things: the causes of exemplary explosions that occurred in the industry; employer’s obligations regarding explosion safety; principles of classification, determining the range, and marking of explosion hazard zones; changes resulting from the new ATEX directive; principles of operation and selection (limitations) of explosion protection measures; principles of carrying out repairs and servicing of devices in explosion-proof design; videos with practical tips.

Why should employees be trained in the requirements of the ATEX Directive?

Statistics: nearly 90% of industrial accidents are due to human actions.

ATEX training is the best and, at the same time, a legally required way to reduce the risk of accidents in Ex zones.

An employee aware of the dangers and their consequences is an employee who can react in time and save the lives of others and the assets of your company.

We are recommended by:

Tomasz Masztakowski

ORLEN Eko – Health and Safety Inspector

Participating in thematic training was certainly not a waste of time. The trainers’ expert knowledge related to specific problematic real-life examples shows the professionalism of the Wolff Group.

Robert Zaborowski

Beckers Group – Production Manager

Thank you for a very interesting and substantive training. I sincerely recommend it to those who want to deepen their knowledge related to ATEX issues.

Rafał Łaskawiec

Entec Solutions – Designer

Thank you very much for the opportunity to participate in the training. It’s been a long time since I attended a training that so strongly consolidated my modest knowledge on this subject.

Grzegorz Bednarek

Walcownia Rur Andrzej – Health and Safety

It’s the first time I’ve encountered such training – more of a discussion and exchange of expert knowledge than a lecture with a presentation. I believe the training was truly valuable – I would like to participate in more in the future.

Highly practical ATEX training program

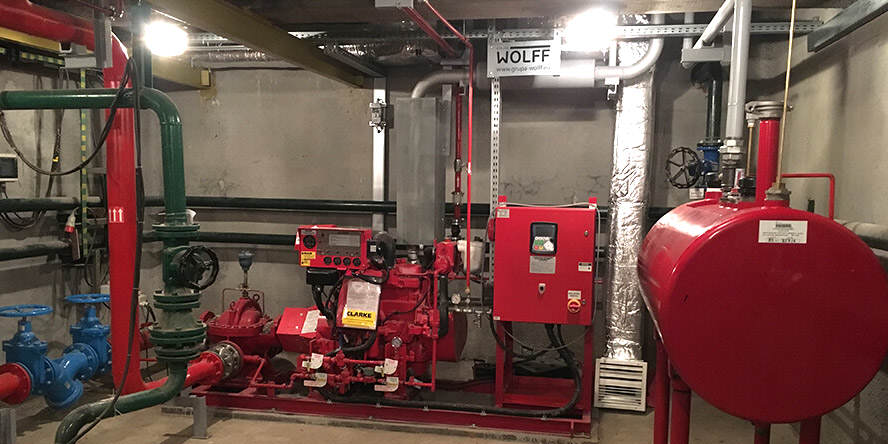

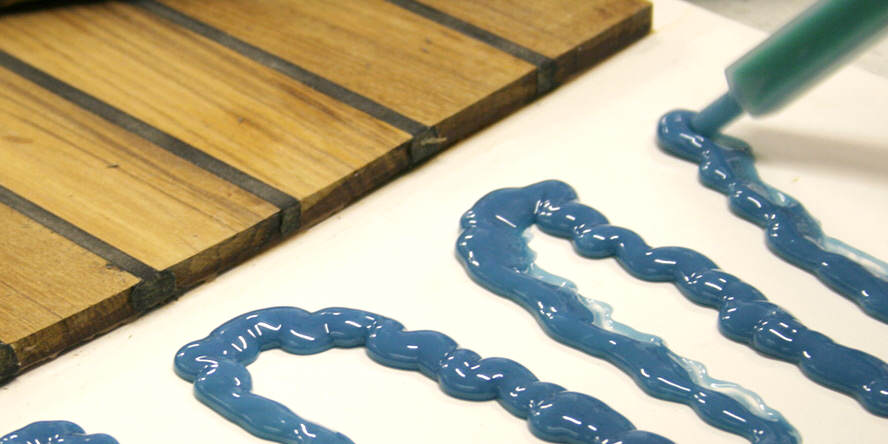

We are not theorists. Over the 25 years of the WOLFF GROUP’s existence, our experts have participated in hundreds of different projects related to ensuring explosion and process safety in industrial plants in Poland. During training, we are eager to share our practical experience, which is especially important for hazards resulting from the possibility of dust explosions. Due to the changing explosion parameters of dust between different industrial plants, or even depending on the place in the process within one installation, the extensive practical experience of the trainer is crucial to ensure the high substantive value of the training.

They trusted us: