95% of Polish companies test the explosivity of dust with us because…

…we are familiar with the requirements of insurers auditing plants, we know how to proceed after an explosion, and we act comprehensively, i.e. from dust testing to auditing the plant to securing it. We are a partner who will help you select the tasks that will add the most to improving safety… a partner who will propose various concepts to you so that together you can choose the best one… a partner who will guide you through the process of improving fire and explosion safety. And all this at your pace.

INSURERS

We know the requirements of insurers. We know what action to take to ensure you get the best possible policy terms.

Read more

We provide substantive support to insurers and brokers during their insurance audits. What is more, we educate the insurance sector by setting the standard for explosion safety. All of this means that we know their expectations and can implement them efficiently.

EXPLOSION

We are working with facilities where an explosion occurred. Therefore, we know how to identify the causes and eliminate them in the future.

Read more

We have repeatedly analysed the causes of dust explosions in various industries and then secured the equipment there to avoid similar incidents in the future. In the last few years alone, we have worked in plants in the energy, food or timber industries where explosions had caused millions of dollars in losses.

EPD / ERA / ATEX AUDIT

We act comprehensively. Based on the results obtained, we can develop an EXPLOSION PREVENTION DOCUMENTT, EXPLOSION RISK ASSESSMENT or ATEX AUDIT.

Read more

Where should you begin? From Explosion Prevention Documents (EPD) or Explosion Risk Assessments (ERA)? How about from the ATEX AUDIT? The first two documents are legally required and should confirm that the workplace in question meets the requirements of the ATEX Directive. An ATEX AUDIT, on the other hand, is the quickest and cheapest method of assessing the condition of a piece of equipment or PLANT with regard to explosion safety. Importantly, the cost of the AUDIT is deducted from the price of the EPD or ERA AUDIT making it ideal for a start-up.

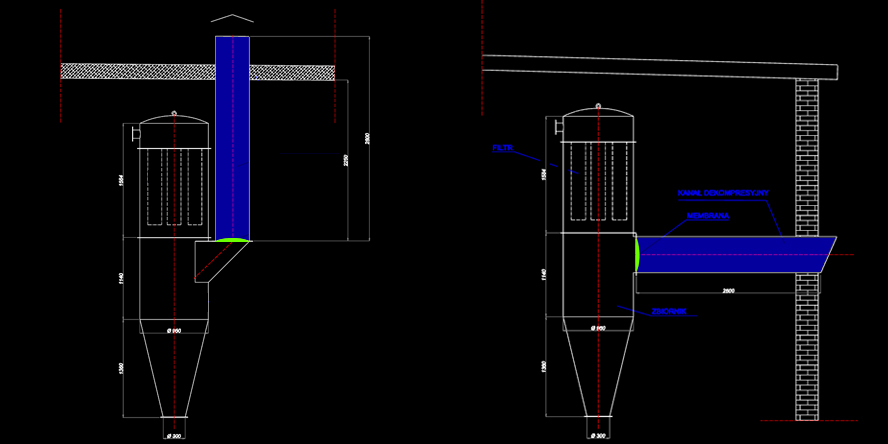

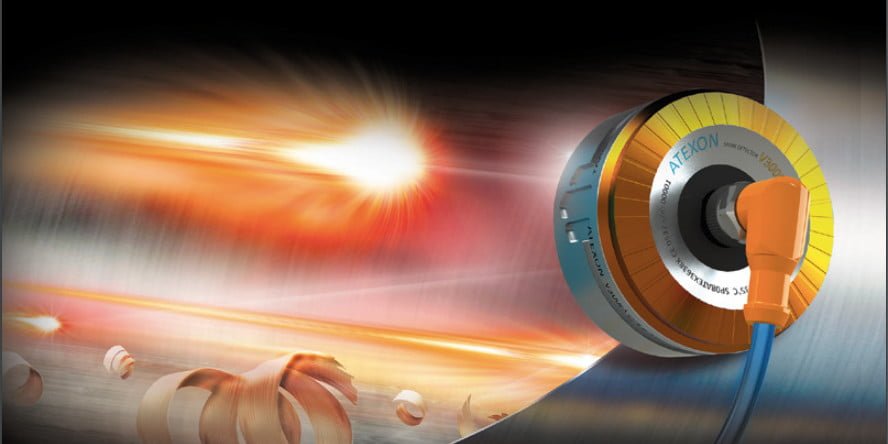

PROTECTION

We will develop an explosion protection concept for your equipment and implement the solution of your choice.

Read more

We can help you determine whether and, if so, what equipment in your facility needs to be explosion-proofed. What is more, we will tell you what equipment poses the greatest risk, so that it should be addressed first. In the next step, we will develop a concept including various ways of protecting your equipment from explosion so that together we can choose the most optimal solution for you.

Testing dust explosivity is intended to answer the question of whether a particular dust type is explosive and, if so, how hazardous it is. For example, it may be that the particular dust is explosive, but its minimum ignition energy is so high that the risk of explosion is virtually non-existent. It may also be the case that the dust is not explosive and thus a full range of tests would generate unnecessary cost. For these reasons, it is extremely important to divide the tests into two stages and to select only those parameters that need to be established. This reduces the cost of testing.

How we reduce the cost of dust explosivity testing

In order to reduce the cost of the study, we divide it into two stages. If the first part shows that the dust is not explosive the tests are discontinued and you pay only a fraction of the amount of the entire test. Similarly, the second part of the test is only performed for dust classified as explosive. At this stage, additional parameters are determined, which are necessary, among other things, for the development of an ATEX AUDIT or Explosion Prevention Document and the selection of explosion protection for the process devices.

1st part of the study

We verify whether the dust was explosive

Pmax

Kst max

2nd part of the study

You only pay if the dust turns out to be explosive

MIE

LEL

T5mm

TCL

Definition of the above parameters

Pmax – maximum explosion pressure

The maximum explosion pressure is a fundamental parameter to consider when protecting an installation from an explosion. At the moment of explosion, the pressure in the device starts to increase until it reaches its maximum level or causes the device to rupture. Experience shows that the Pmax value for the vast majority of dusts ranges from 2 to 10 bar. However, there is a narrow group of dusts for which the maximum explosion pressure can significantly exceed 10 bar – these are mainly metal dusts.

The Pmax parameter is determined experimentally. For this purpose, a series of dust-air mixture explosions are carried out in a special tank.

Kst max – explosion severity index

This is an index that characterizes the explosion dynamics of a given dust suspended in the air. The higher the Kst max, the faster a given explosion will reach its maximum pressure. It is one of the key parameters considered when selecting explosion protection measures.

It’s important to properly understand this parameter. The time from initiating the explosion to reaching the maximum explosion pressure is always very short, often significantly less than a second. If we were to compare the explosion of two dusts with the same maximum explosion pressure (e.g., Pmax = 5 bar g) and extremely different explosion severity indices (e.g., Kst max = 50 and 500 bar∙m/s), it would turn out that the only difference is that one developed to its maximum level in the time of one blink of an eye, and the other in the time of three blinks. These differences are huge for explosion protection measures but practically imperceptible to humans.

The Kst max parameter is determined experimentally. For this purpose, a series of dust-air mixture explosions are carried out in a special tank.

The Kst max index is the basis for the classification of flammable dusts. The explosion severity classification is presented in the table below.

| Explosion severity class | Kst [bar∙m/s] | Name |

| St 1 | 0 < Kst < 200 | Explosive |

| St 2 | 200 < Kst < 300 | Highly explosive |

| St 3 | Kst >300 | Extremely explosive |

Kst max – Explosion severity index (EN 14034-2+A1:2011)

MIE – minimum ignition energy

The minimum ignition energy describes the susceptibility of a given substance to ignition due to various ignition sources. This parameter is extremely important for the explosion risk assessment process and ATEX AUDIT. As a rule, the lower the ignition energy of a given substance, the higher the probability of an explosion. Contrary to popular belief in the industry, there are many dusts that can be ignited even by an electrostatic discharge.

Below we present several exemplary values of the minimum ignition energy for dusts. It should be emphasized here that this value depends on several factors, such as the humidity of the material or the diameter of its particles. Therefore, the best practice to determine the MIE for a specific dust is to conduct its tests.

| Dust cloud | Minimum ignition energy [mJ] |

| Wheat flour | 50 |

| Sugar | 30 |

| Aluminum | 10 |

| Epoxy resin | 9 |

| Zircon | 5 |

| Some pharmaceutical intermediates | 1 |

LEL – Lower Explosion Limit

A dust-air mixture becomes explosive upon reaching an appropriate concentration. The designation of the lower limit LEL occurs after a series of tests in a spherical chamber. In most cases, it falls within the range of 20-60g/m³. For dusts, the upper explosion limit is not determined.

T5mm – ignition temperature of a 5 mm dust layer

It indicates the lowest temperature of a hot surface at which ignition occurs for a dust layer of a specified thickness located on that surface. Standards typically suggest performing determinations for a dust layer with a thickness of 5 mm.

TCL – cloud dust ignition temperature

This parameter indicates the lowest temperature of the hot inner wall of the furnace at which ignition of the dust cloud in the air inside the furnace occurs. The tubular furnace known as the Godbert-Greenwald furnace is used to determine the minimum cloud dust ignition temperature.

And this is where the second area of potential savings comes in. With nearly 30 years’ experience, we are able to identify only those parameters of explosivity and combustibility of dust that are crucial for a given situation. In other words, instead of recommending all available tests to perform, we offer only those that will be necessary, thus reducing the cost by about half.

Free consultation with explanation of the results

Is Kst max = 53 [bar∙m/s] a lot or a little? With what parameters are we on the safe side? If the MIE (minimum ignition energy) of the dust exceeds 3.43 J, should electrostatic earthing be used? Raw figures may not tell you much, which is why we will offer you a free online meeting, after your dust explosivity study, where our engineers will discuss the test results. They will explain you what to pay special attention to and what you can disregard. If the situation requires further action then we will point you towards specific solutions.

Check the answers to the above questions

Is Kst max = 53 [bar∙m/s] a lot or a little?

The Kst max parameter, which tells us about the explosion dynamics, is used to select the explosion protection. From this perspective, the value 53 is low, which means that we will be able to use most types of explosion protection solutions. The fact that its value is low is also proven by the table below, which is used to classify explosive dust.

| Explosion class | Kst [bar∙m/s] | Name |

| St 1 | 0 < Kst < 200 | Explosive |

| St 2 | 200 < Kst < 300 | Highly explosive |

| St 3 | Kst >300 | Extremely explosive |

On the other hand, every explosion, regardless of the Kst max value, reaches its maximum pressure within fractions of a second. If, therefore, the maximum explosion pressure Pmax exceeds the design resistance of the equipment in which the explosion occurred, destruction will occur, regardless of the value of Kst max. To make a complete picture, let us add that the structural strength of most equipment (dust collectors, cyclones, silos, bucket elevators) is in the range of 0.4 – 1 bar g.

With what parameters are we on the safe side?

The only case where we are completely safe is when the tests demonstrate that the dust in question is non-explosive. In any other case, adequate organisational (e.g. procedures) and/or technical (e.g. explosion protection) measures should be taken to ensure an acceptable level of protection.

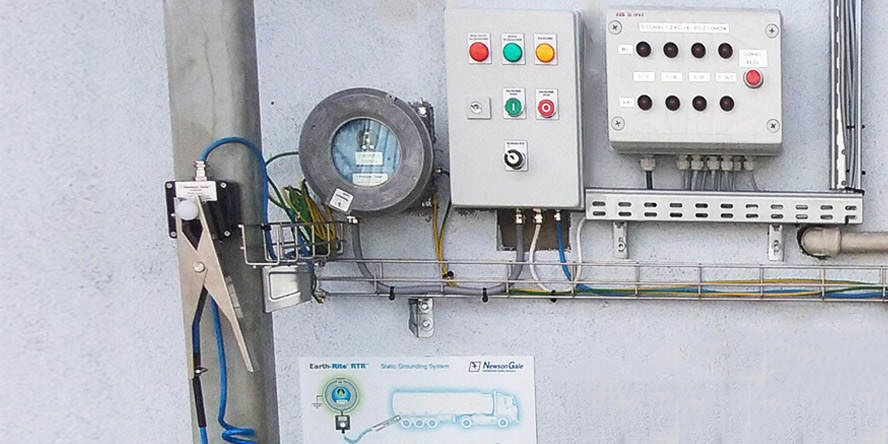

If the MIE (minimum ignition energy) of the dust exceeds 3.43 J, should electrostatic earthing be used?

This high minimum ignition energy means that the use of electrostatic grounding is not required in the vast majority of cases. This is because it is very difficult to achieve such a high level of electrostatic discharge energy in practice. For example, the energy of an electrostatic discharge can reach the following values:

- human: 90 mJ (premises: human electrical capacitance 200 pF; electrical charge level 30 kV [IchemE])

- bucket: 9 mJ (premises: electrical capacitance of a bucket 20 pF; electrical charge level 30 kV [IchemE])

- road tanker 2250 mJ (premises: electrical capacitance of a bucket 5000 pF; electrical charge level 30 kV [IchemE])

However, it should be noted that the MIE for many dust types ranges from a few to a few tens of milliseconds. Below, values for several common industrial dust types are shown.

Minimum ignition energy of dust

| Dust cloud | Minimum ignition energy [mJ] |

| Wheat flour | 50 |

| Sugar | 30 |

| Aluminum | 10 |

| Epoxy Resin | 9 |

| Zircon | 5 |

| Certain pharmaceutical intermediates | 1 |

Your dust is explosive. What next?

The mere fact that dust is explosive does not make it possible to assess whether the probability of an explosion in a particular plant is high, medium, low or negligible. Moreover, it may be the case that the risk of an explosion in a particular piece of equipment is high, but the consequences are negligible, i.e. the likelihood that people will suffer in the event of an explosion, and that the material loss will be significant, is small. As a result, each device will pose a different level of risk. Which one will you start the changes with? The answer is simple. From the one where an explosion and fire are most likely to occur and the potential impact is most severe. Find out how we can help you assess individual pieces of equipment and improve their safety.

ATEX Audit

The quickest and cheapest way to determine whether a plant or production facility meets the minimum requirements of the ATEX directive.

Read more

The study indicates which areas need to be addressed first. The document often forms the grounds for discussions with superiors or management, and its cost is deducted if an explosion risk assessment (ERA) or explosion protection document (EPD) is completed in the next step. An additional advantage is that the ATEX AUDIT records do not make it into an official document. An explosion protection concept for a plant may be part of the audit report.

Explosion risk assessment / EPD

These are studies required by law that discuss explosion safety issues in the most comprehensive manner.

Read more

On the one hand, their complexity is a considerable advantage but, on the other hand, it entails several risks. For example, the time required to develop an ERA or EPD often exceeds 5-6 weeks and the cost of development significantly exceeds the development of an ATEX AUDIT.

Implementation of a protection system

Sometimes the level of risk is unacceptable and therefore explosion protection is required.

Read more

In such cases, we will prepare for you concepts for the explosion protection of the plant (in one or more variants) together with a cost estimate. If you accept it we will move on to its implementation. Importantly, we prepare a concept based on all types of protection (explosion suppression, explosion relief, flameless explosion relief and explosion isolation). In this way, we are able to adapt the concept to your specific facility. Remember also that the safety concept can also form part of an ATEX AUDIT.

Dust explosivity testing – scope of study

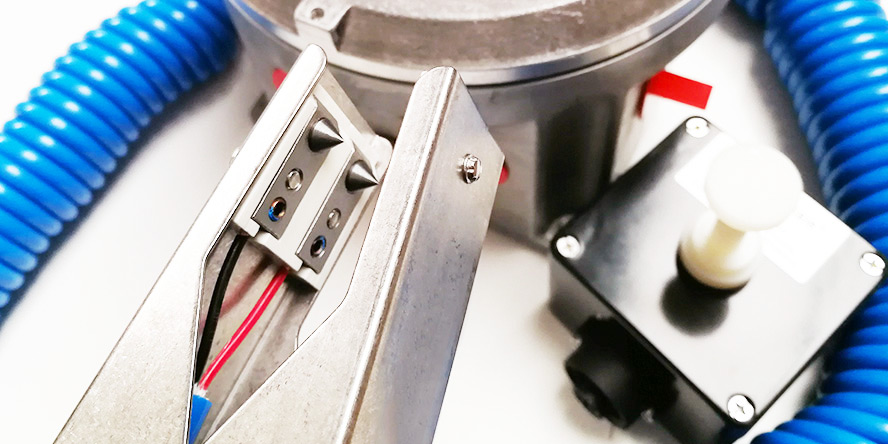

In order to determine the degree of hazard posed by a given dust type, a range of equipment is used to determine flammability and explosivity. Importantly, the laboratory where we perform the tests has two explosion testing facilities (explosion autoclaves) with volumes of 20 dm³ (standard) and 1 m³ (“golden” standard) at atmospheric temperature (25°C) and elevated temperature (up to 200°C). All tests meet the requirements of the ISO 9001 quality system.

Maximum explosion pressure (Pmax) – the maximum pressure occurring in a closed vessel during an explosion of an explosive atmosphere, determined under specified test conditions

Maximum rate of explosion pressure rise (Kst max) – the maximum value of pressure rise per unit time during explosions of all explosive atmospheres within the explosive range of a flammable substance in a closed vessel under specified test conditions

Minimum ignition energy (MIE) – the lowest energy sufficient to cause ignition of the most readily ignitable explosive atmosphere under the specified test conditions.

Minimum dust cloud ignition temperature (TCL) – the lowest temperature of the hot, inner wall of the furnace in which the dust cloud ignites in the air contained inside the furnace

Ignition temperature of a dust layer (T 5mm) – the lowest temperature of a hot surface at which a dust layer of a given thickness on that surface ignites

Lower explosive limit (pol. DGW, ang. LEL) – lower limit for the concentration of a flammable substance in air at which an explosion may occur

Explosive dust types most commonly found in industry

It can be assumed that all organic dust types are explosive. But that is not all, not everyone is aware that multi-metal dust types are also explosive. Moreover, they are particularly dangerous because they burn very rapidly, which makes it very difficult and requires a great deal of experience to protect against the effects of an explosion such as aluminium dust. Below is a list of those explosive dust types that are most common in industry.

Food and agricultural products

Cotton

Egg protein

Fiber / Cellulose

Hops

Sugar

Corkwood

Gluten

Tea

Cocoa

Semolina

Coffee

Lactose

Alfalfa

Wood flour

Oatmeal / oat bran

Wheat flour / wheat bran

Soy flour / soy bran

Powdered milk

Spices

Whey

Flaxseed

Lemon zest

Rice starch

Corn starch

Wheat starch

Potato starch

Malt

Dried fruits and vegetables

Tapioca

Tobacco

Oat grain

Metals

Aluminum

Bronze

Zinc

Magnesium

Solid fuels and their derivatives

Biomass

Coke

Soot

Lignite

Charcoal

Bituminous coal

Chemical substances

Anthraquinone

Sodium ascorbate

Aspirin

Adipic acid

Ascorbic acid

Maltodextrin

Calcium acetate

Paraformaldehyde

Sulfur

Lead stearate

Sodium stearate

Calcium stearate

Plastics

Urea formaldehyde

Melamine

Polyvinyl derivatives

Polyacrylamide (PAM)

Methyl polyacrylate

Polyacrylonitrile (PAN)

Polypropylene (PP)

Polyethylene (PE)

Epoxy resin

Phenolic resin

Melamine resin

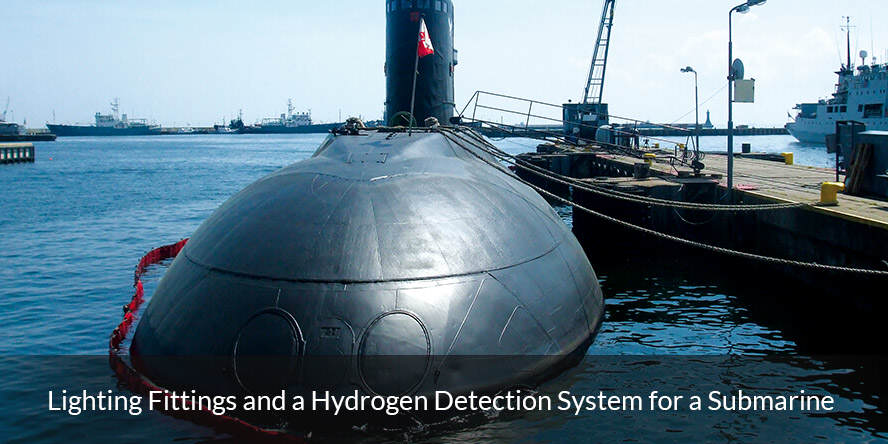

Flammable dust explosion tests

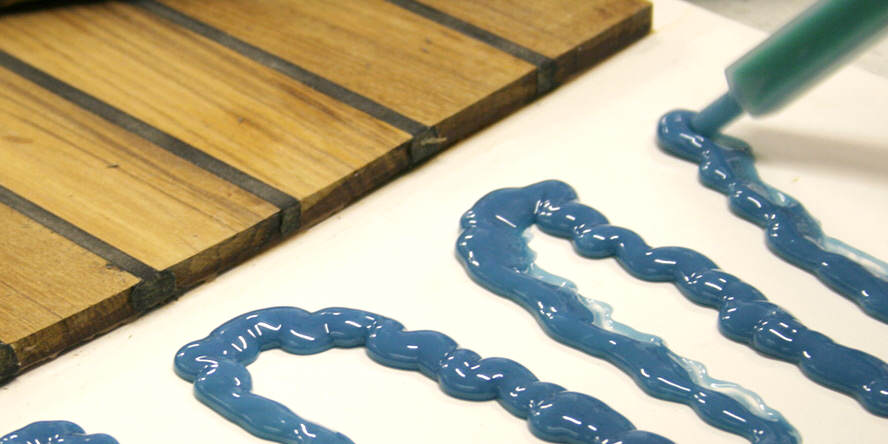

We provide ATEX training supported by live explosion demonstrations during which the participants can see, in addition to the factual knowledge provided by long-standing practitioners, the powerful force behind substances commonly used in industry (coal dust, sugar, coffee, tea, etc.).

The explosion demonstrations we organise are intended to raise awareness of serious risks involved in the processing and storage of flammable and therefore explosive products or substances. This is particularly true in the wood, food, chemical, pharmaceutical and energy industries. Accidents involving combustible dust, liquids or gases can completely destroy production facilities, but also endanger human lives.