Fire protection systems

for industry

- we match the requirements of insurance companies with your possibilities

- we minimise the impact of assembly on production continuity

- providing security in new and old facilities

We will answer questions about: offer, technical specification, delivery, assembly.

FROM PROJECT TO SERVICE:

Fire protection systems and fire protection features

Designing and installing explosion protection devices for industrial plants. We specialise in implementing fire systems in already operating plants, so we know how to minimise the impact of our work on your production. Experience in timber, energy, food and beverage, waste processing and chemical and petrochemical industries, so you are guaranteed fire protection installations tailored to your specific plant. Importantly, we operate in accordance with Polish standards and VdS, FM GLOBAL and NFPA guidelines.

We specialize in

Fire safety guidelines and standards

- PN-EN

- VdS

- FM Global

- NFPA

Industrial facilities

- energetics

- wood industry

- food industry

- waste processing

- chemicals and petrochemicals

Corrosive environment

- we select plant components to suit your operating environment

- experience in “difficult” industries

- including C5M/C5-I corrosive environments

Designing fire installations in compliance with the requirements of insurance companies

We are aware that most of investments in upgrading the fire protection system is due to the requirements placed on industrial plants by insurance companies. If you found yourself in such a situation, it is likely that the insurance company has indicated the standard or regulations for the fire protection systems to be implemented. The most important information for you is whatever requirements your insurer has outlined for you, we will meet them all.

The principle of fire systems

The fire systems are designed to detect a fire and minimise the effects of a fire, thereby protecting people and property. Simple fire systems consist of fire detectors, smoke detectors, a control panel and fixed extinguishing equipment, e.g. a network of pipes with extinguishing agent complete with discharge nozzles. We can divide the fire systems into four main types, depending on the extinguishing agent used: water, water mist, foam, and gas extinguishing systems.

Design of fire systems

We design fire protection systems in accordance with legal regulations and the requirements of guidelines and standards, such as: VdS, FM Global, NFPA, EN. For example, the need to install fire systems is not always a direct result of requirements of the insurance company. The regulations allow to increase the area of fire zones if fixed fire extinguishing equipment is used.

If you are determined to implement new fire safety features, the next step is to choose the standard of design and installation. As we already mentioned, sometimes the standard to use is imposed by the insurance company, other times, you can choose it yourself. We are happy to help in this area, if you need advice – write to us.

These standards detail all the information we use to perform calculations and design fire systems. It is important to note that, although all standards detail the same basic parameters that we take into account for the design, the values of these parameters may be different for each standard. This is why it is so important to stick rigorously to the adopted standard afterwards. Of these parameters, the following should be mentioned first and foremost:

- sprinkling surface

- intensity of sprinkling

- the area protected by one sprinkler/deluge sprinkler

- operating time of the installation

Completed fire protection projects

Sprinkler installation for a multinational chocolate company.

Scope of activities: detailed design; fire mains connections and connecting them to the existing installation; wet and dry system sprinkler systems; reinforcement of the production hall and warehouse structures.

Hydrant system for a combined heat and power plant

Scope of activities: installation of an internal hydrant system connecting 11 hydrant risers; installation of emergency supply stations for the main hydrant risers; comprehensive implementation of the installation work without disrupting the CHP plant’s operation, in compliance with strict health and safety standards

Foam extinguishing system for waste sorting plant

Scope of activity: cooperation with a fire expert; securing two halls of an active waste processing plant with a total area of 1024 m2; design, installation and commissioning of a fire extinguishing system based on so-called foam monitors; obtaining permits, expert opinions and approvals.

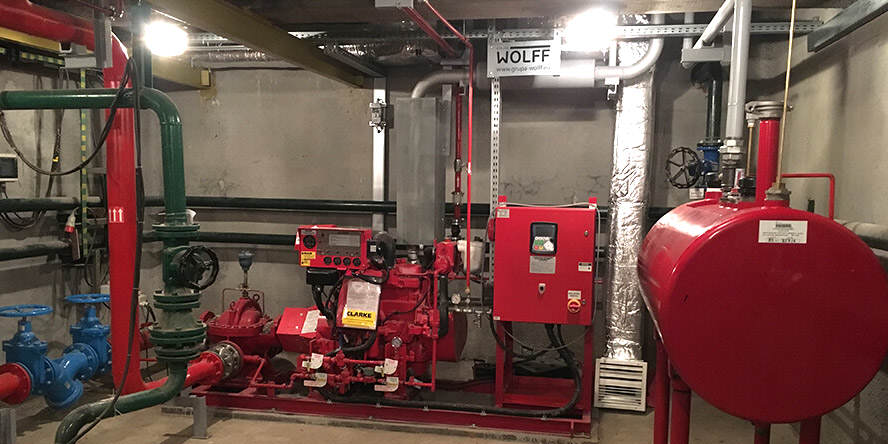

Fire fighting water storage tank and fire pump house for a CHP plant.

Scope of activities: design, installation (to replace the fire pump house) and commissioning; the fire fighting water storage tank with a capacity of nearly 1000 m3; obtaining the necessary permits

Fire systems – the offer

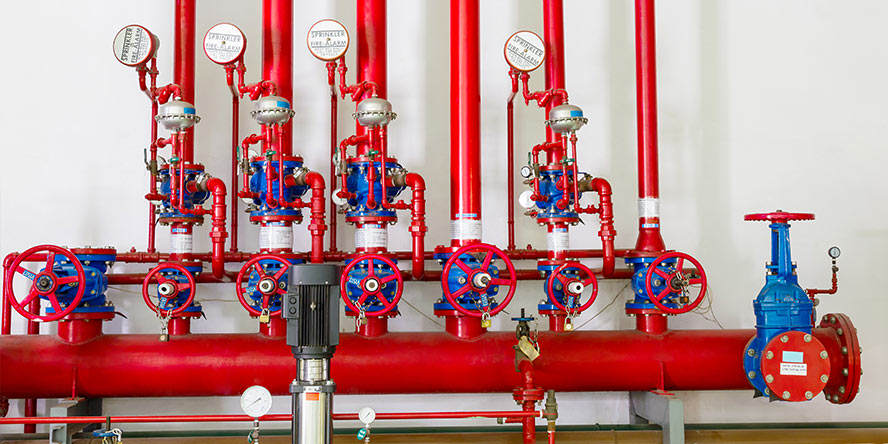

Sprinkler systems.

They are self-contained fire extinguishing systems that detect the moment a fire starts, then send information to the control system and automatically start the process of selective water extinguishing – only where there is a fire.

Deluge sprinkler systems.

They are equipped with open fire nozzles and can be divided into several extinguishing zones. When a fire is detected, the sprinkler valves for the area open. Water is released throughout the protected area.

Foam installations.

In particular, we use them for facilities with a high fire risk, such as: tanks for fuels, solvents and other flammable liquids; warehouses for plastics; warehouses for flammable products and/or locations where explosive atmosphere occurs.

Fire Detection and Signalling.

Designing and implementing comprehensive fire detection and alarm systems. Depending on your needs, we use one of the four available systems or a combination of two or three of them, to optimise your investment from a technical and cost perspective.

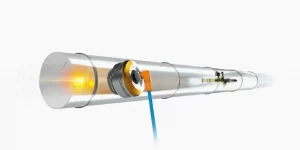

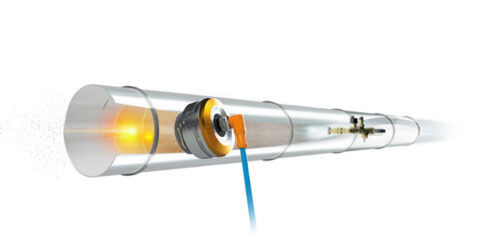

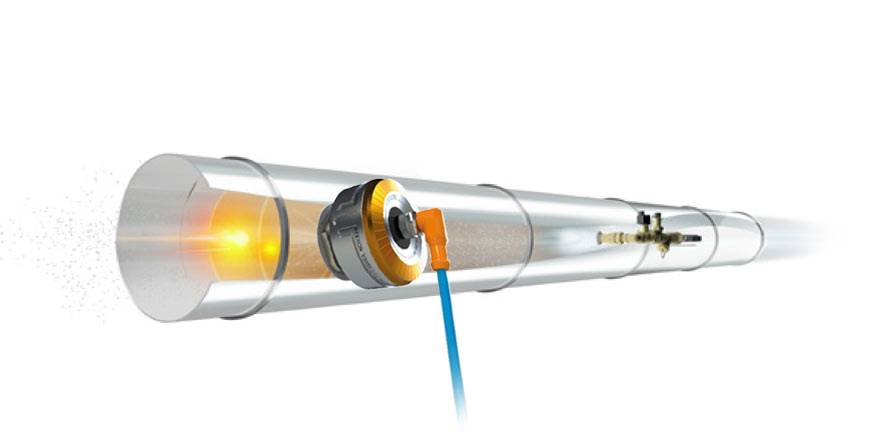

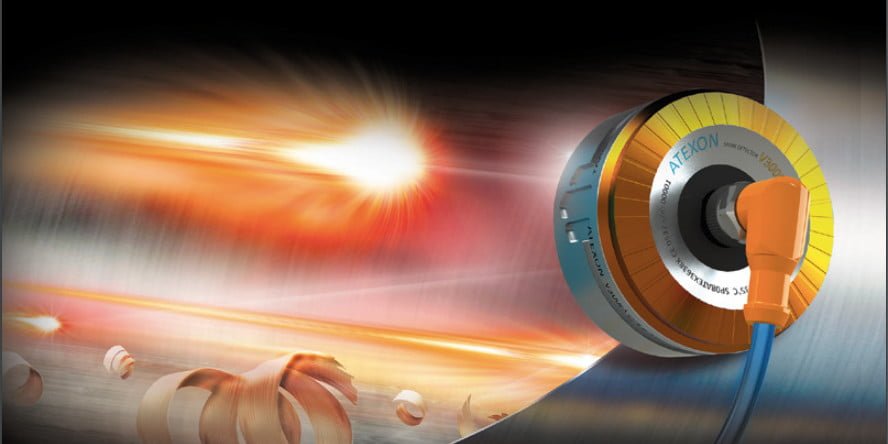

Spark Detection and Extinguishing.

These systems are designed for installation in the ducts of industrial installations. Their purpose is to prevent a potential ignition source in the form of a spark, cigarette butt or heated particle from entering the appliance.

Secure your installation.

How do we reduce the impact of fire installation on plant operations?

We work on designated days and times, at nights or weekends. We plan activities in collaboration with maintenance and production. The purpose of all this is to eliminate or minimise the impact of the installation of fire protection systems on the production continuity. For the installation teams, the easiest thing to do would be to enter the site, take individual installations out of production and quietly do their job. But for your plant, every hour of downtime means a real cost. For us, this is obvious.

EFFICIENT, SAFE INSTALLATION WITHOUT AFFECTING PRODUCTION.

Eliminating/minimising production downtime.

Coordinating closely the assembly with production planning and UR.

We determine what we will bring to the site, e.g. skips/scaffolding/high-rise workers.

We follow all of your site’s internal procedures.

If necessary, we also work nights or weekends.

We move and work only in the areas which were made available to us.

We protect your machinery and equipment before installation.

After completing installation, we clean up to let you resume production as soon as possible.

Fire installation work for equipment and infrastructure

The safety of the owner’s infrastructure, machinery or individual equipment is our top priority. We are aware that in the case of a fire system upgrade at an active facility, any damage to the technology could have a critical impact on production continuity.

BEFORE INSTALLATION

We define the scope of work with the owner

Read the safety guidelines carefully

We secure the workplace before starting work

Covering machinery and equipment

DURING AND AFTER INSTALLATION

We take extreme caution when moving on the premises

We take care not to damage anything

Thoroughly clean the site after installation

We ensure rapid restoration of production

Why do customers choose us?

We take care of the details.

How else does a fire system upgrade on an active plant differ from an investment in new buildings? These are, first and foremost, any requirements related to the owner’s internal procedures within the production building or the plant as a whole. Our site managers and fitters are used to meticulous safety procedures, weighing cars at the entrance and exit of the plant, the need to have all the necessary passes and regular contact with the client’s representatives, hygiene requirements especially in food production, or having a valid SANEPID (in Poland: health department) booklet also in the food industry.

Advice on how to prepare a plant for the start of work

We realise that for you such a fire installation upgrade is also a challenge. It is highly likely that no changes have been made to fire protection since the construction of the production halls or the warehouse. Due to that we also provide advice, based on our previous implementations, on how to prepare the production facility and crew for such work. We are at your disposal at all times, so that you always have the feeling that everything is running according to schedule, with no impact on production and storage processes

We operate to all standards and norms.

In our experience, the majority of investments in upgrading fire protection systems and installations start after the insurer’s audit. The requirements of an insurance company which apply to fire protection investments usually explicitly state the standards and/or norms to which the required solutions are to be designed and constructed. These could be requirements listed in the EN standard, or VdS, FM Global or NFPA standards. Whatever the requirements your insurer has outlined for you, we will meet them all.

Fire protection of production buildings in continuous operation – frequently asked questions

Check the documents first. Find out whether you have an up-to-date fire safety manual that contains factually correct information about the individual buildings and their current production use. If your fire safety manual is out of date, contact your fire officer for an update. At the same time, contact us to discuss the initial assumptions made by the insurer and to discuss what such a project might look like from the supply and installation side of fire protection systems.

Keep calm We have experience in this type of projects. The key to success is proper coordination of our work with maintenance and production planning. Our managers and fitters are like Himalayan climbers – they wait for the ‘weather window’, i.e. permission to enter a specific zone, to carry out the work, so that they can proceed to the summit attack, i.e. the ultimate success of the project. Sometimes it happens during the day, sometimes at night. Sometimes we can work for the whole day, other times only for 2 hours on a given day. We are used to this variability and know how to plan our work with this type of specificity of carrying out the works.

Large equipment resources could be worth many millions of zlotys. It is not without reason that experience becomes crucial to maintaining safety on such projects. Once a specific work zone has been made available to us, we first secure all the machinery and equipment operating there. Our staff are sensitive to ensuring that, when moving, no such activities are carried out that could lead to damage to your property. When the work is finished, we clean up thoroughly and restore the work zone to the state we found it when you made it available to us.

Fire retrofit activities are not common. It may be that no such works had ever taken place at your site since the plant was built. Hence you may not have developed any procedures for such situations. Based on our experience from previous projects, we will advise you on what activities are worthwhile in terms of organisation to make our cooperation run smoothly.

Of course. We have carried out quite a few projects in the food industry, so we have really extensive experience in this area. We are aware of the need to maintain hygiene standards, to have valid SANEPID tests. We understand the stringent requirements that may be imposed by the owner to protect the manufactured products from contamination. We follow all the requirements defined by the owner.

Fire Protection Solutions

Foam fire suppression systems

The foam fire suppression systems are used for areas at a high risk of fire, storage tanks for fuels, solvents and other flammable liquids, plastic material storage units, flammable and/or potentially explosive atmosphere storage areas, and chemical processing plants.

Smoke removal and ventilation system

We design and implement ventilation and smoke removal systems for enclosed structures, escape routes and staircases. We supply the proposed solutions complete with fire detection and alarm systems as well as emergency and escape route lighting. We may integrate them with the existing safety systems, too. The comprehensive task performance may also comprise design and provision of fixed fire-fighting systems.

Fire detection and alarm system | fire alarm system (FAS)

We design and implement fire alarm systems as well as complete fire-fighting systems. The latter may comprise fixed fire-fighting systems, voice alarm systems, emergency and escape route lighting, ventilation and smoke removal systems, as well as gas detection systems. Within such comprehensive approach we assume full liability to deliver a cohesive fire-fighting system. At the same time, we guarantee integration of the existing structure with the newly implemented safety systems.

Wireless fire detection and alarm system | fire detection system

We design and implement wireless fire detection and alarm systems which do not require traditional cabling. Such solution is simple and fast to install, and at the same time extremely aesthetic (the sub-assemblies imitate marble and wood or may be finished to RAL colours). All that makes such systems ideal for buildings where interior must remain intact, high aesthetics is important and the simplicity of installing wires is crucial. This refers mainly to historic buildings, religious buildings or heritage monuments under the supervision of heritage conservation officer (churches, museums, cathedrals). The proposed wireless fire detection and alarm system may be easily integrated with the traditional systems of other manufacturers.

Smouldering fire detection | fire detection system

We provide comprehensive implementation of smouldering fire detection and alarm systems, which are mainly used in protecting belt conveyors, tunnels, silos, dispensers, storage yards, bulk material storage facilities as well as hardly accessible places. The proposed solution frequently detects fire before the typical symptoms such as smoke or flame, which are detected by the traditional systems, appear. Thus, actions may be taken earlier and the risk of fire spreading is minimised, which also refers to the risk of losses resulting from system or product flooding. The smouldering fire detection systems designed by us are based on fire gas detectors and infra-red heat detectors, thanks to which they prove to be useful in difficult industrial conditions (high-dustiness and humidity), which may be found in power plants, cogeneration plants, cement plants or wood and cellulose processing plants.

Line temperature sensor | fire detection system

We design and implement complete fire detection and alarm systems based on a line temperature detector (or other detectors selected adequately to the working conditions), which is a special active cable with embedded sensors. The solution is intended to be applied in hardly accessible spaces or when temperature measurement is required along long sections reaching from several dozens to several thousands meters. Typically line temperature sensors are applied in detecting belt conveyor failures or fires, cable routes overheating, detecting fires in transformer rooms, tanks, tankers and pipelines temperature monitoring. The line temperature sensor precisely indicates the source of fire or overheating of the monitored equipment or cable route.

Ex-rated audible and visual alarm devices

Within the Ex-rated audible and visual alarm devices we offer manual call points, multicolour signal lamps, visual alarms, alarm sounders, strobe light sirens and heat detectors. All devices are intended for operation in explosion hazard zones.

Gas extinguishing systems

We design and implement gas extinguishing systems as well as complete fire safety systems, which comprise: the systems for fire detection, alarm and extinguishing, ventilation and smoke removal, emergency and escape route lighting, CCTV, access control as well as time and attendance control.

Sprinkler systems

We design and implement sprinkler systems as well as complete fire-fighting systems (fire detection, alarm and extinguishing, ventilation and smoke removal systems, emergency and escape route lighting, CCTV, access control as well as time and attendance control).

Deluge systems

As one among the few we focus on accomplishing difficult tasks mainly in the industrial sector, with unfavourable working conditions (high dustiness, humidity, variable temperatures, explosion hazard zones).

Spark extinguishing systems

We design and implement spark extinguishing systems intended to be installed in industrial systems ducts. Their task is to prevent the potential ignition source in the form of a spark, cigarette butt, or heated particle getting inside an equipment with explosive atmosphere.