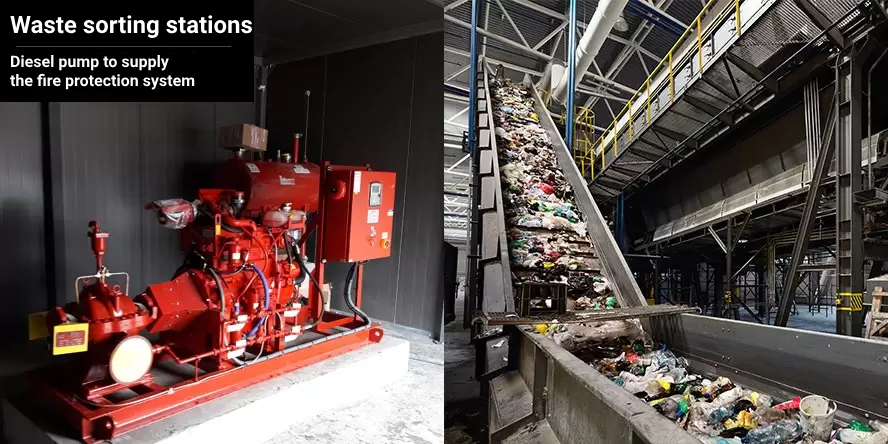

We provide fire protection for sorting plants in accordance with new legal requirements

The increase in the number of fires at waste sorting and storage sites has led to radical changes in the law. The Ministry of Internal Affairs and Administration has decided to issue a new Ordinance on fire protection requirements to be met by buildings or parts thereof and other places intended for the collection, storage or processing of waste. An important change is the need for fire protection. The regulation introduces requirements for the use of fire alarm systems and alarm or smoke extraction equipment.

We act in accordance with

Fire safety measures implemented

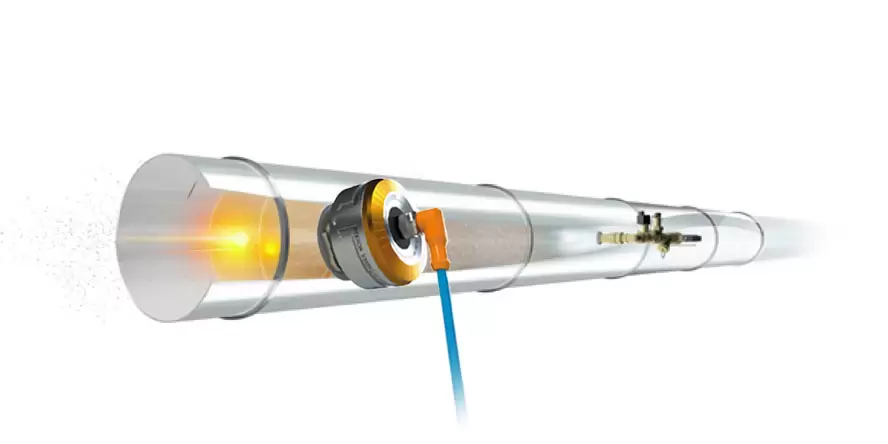

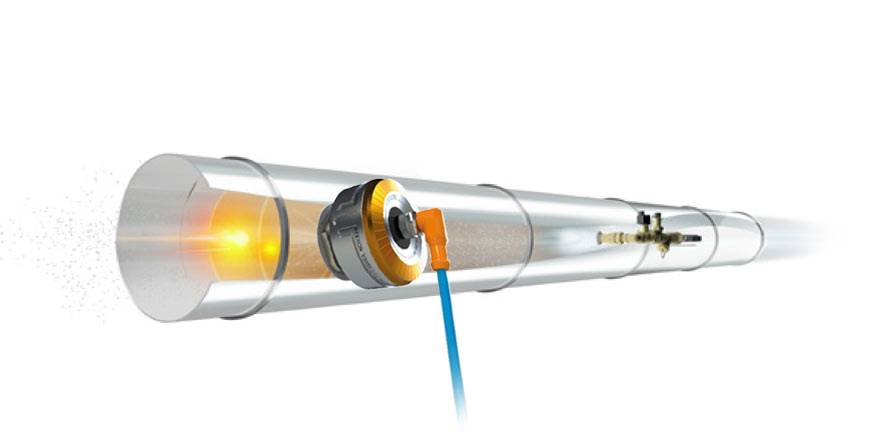

Foam extinguishing – effective for waste sorting plants

So far, fires in sorting plants and waste collection areas have most often ended with the facility burning to the ground. The rapidly growing fire quickly covered a large area. At the same time, large quantities of dark, toxic smoke were forming, which posed a danger to both the environment and people. Due to the variety of materials stored, you never know which way a fire will develop and whether dangerous explosions will occur. This is why it is so important to protect such plants with an effective fire protection system. Practice has shown that foam extinguishing systems work best in such conditions.

Do you need support in protecting your waste sorting plant against fire and meeting the requirements of the Ordinance? We have already completed such projects and would be happy to help you too!

One-stop service

Installation of a fire prevention system requires a lot of work on the investor’s facility. It is always worth ascertaining whether a potential contractor offers an all-in service or whether you will have to coordinate the work of several companies in parallel. Working with us to protect your waste treatment facility against fire, you are assured that we take responsibility for the entirety of the work that we will determine during the site visit.

Detailed design of a foam cannons system.

Installation, commissioning and servicing of systems completed

External fire water tank including foundation

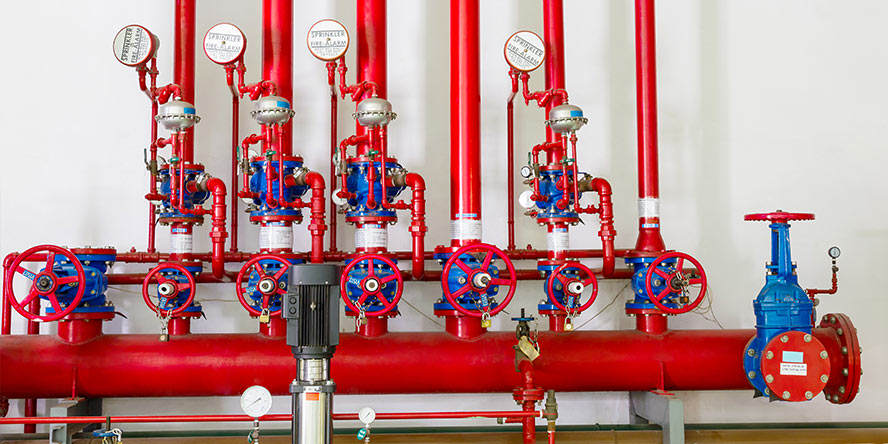

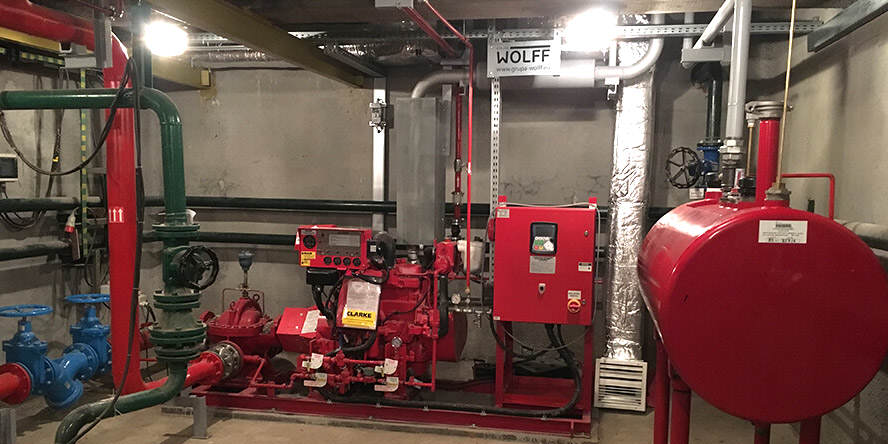

Pumping station (e.g. container) with diesel pump, foam tank, fittings and equipment

Connection between the pumping station building and a hall with fire protection PEHD pipes

Completion of a water supply to the fire reservoir.

Laying power cabling from the transformer station to the fire pumping station.

Manifold design with electrically operated flooding stations

Installation of the piping, fittings, nozzles including fittings and fixing system

Training in the use of the security features installed

Why are there fires in waste sorting stations?

Waste sorting stations, as well as other parts of the systems in waste management plants, are characterised by a high risk of fire. This is due to the following reasons:

- Such systems have a high fire load density due to the accumulation of large amounts of combustible materials in a relatively small area

- It is difficult to determine and control the composition of the waste and the gases emitted from it, which means that it is difficult to predict what will cause the fire and what material will be burnt. A common cause of fires, which is listed by the fire brigade, is the self-ignition of the gases released.

- A large part of the problem mentioned in the above point is the problem of waste collection companies, which often hide one waste in another to “get rid of the problem”. This causes the sorting station to receive materials that pose a fire hazard, for which a given sorting line is not prepared.

- Because of the above-mentioned variety of matter that starts to burn, these fires are violent and spread rapidly

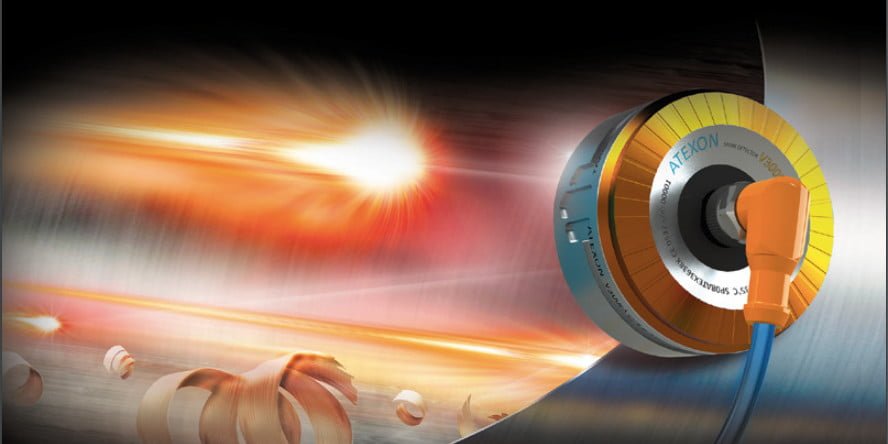

- When opening bags and shredding waste, there are frictional forces (the harder the materials, the higher the forces), or during metal shredding by shafts and blades in shredders. The resulting hot particles can be an obvious source of a fire.

- Similar frictional forces leading to ignition can occur on conveyor belts or when transporting waste with loaders-excavators on sorting lines. The latter is risky not only because of the frictional forces but also because of the fire medium’s supply in the form of oxygen. Before sorting, it happens that the waste lies for a long time without being moved. If chemical or biological waste or, for example, damaged batteries are included, they start to generate heat, which, when the waste is moved, receives an inflow of oxygen, which makes ignition possible.

Why do customers choose us?

We take care of the details.

How else does a fire system upgrade on an active plant differ from an investment in new buildings? These are, first and foremost, any requirements related to the owner’s internal procedures within the production building or the plant as a whole. Our site managers and fitters are used to meticulous safety procedures, weighing cars at the entrance and exit of the plant, the need to have all the necessary passes and regular contact with the client’s representatives, hygiene requirements especially in food production, or having a valid SANEPID (in Poland: health department) booklet also in the food industry.

Advice on how to prepare a plant for the start of work

We realise that for you such a fire installation upgrade is also a challenge. It is highly likely that no changes have been made to fire protection since the construction of the production halls or the warehouse. Due to that we also provide advice, based on our previous implementations, on how to prepare the production facility and crew for such work. We are at your disposal at all times, so that you always have the feeling that everything is running according to schedule, with no impact on production and storage processes

We operate to all standards and norms.

In our experience, the majority of investments in upgrading fire protection systems and installations start after the insurer’s audit. The requirements of an insurance company which apply to fire protection investments usually explicitly state the standards and/or norms to which the required solutions are to be designed and constructed. These could be requirements listed in the EN standard, or VdS, FM Global or NFPA standards. Whatever the requirements your insurer has outlined for you, we will meet them all.

Sorting stations — an important recycling cell that generates huge costs in case of fire

The Regulation of the Ministry of the Interior and Administration mentioned above is only a consequence of the changes in our country in terms of recycling. The amended law on maintaining cleanliness and order in communes imposed a clear increase the required level in recycling. In 2021, this was already at 50%. For this reason, municipal waste (both mixed and sorted) must be recycled at waste management sites.

These processes are carried out by adapted sorting stations, which most often form an integral part of the entire waste management plant complex. An exemplary sorting station line consists of:

- Bag opener

- Pre-segregation chamber

- Rotating screen

- Opto-pneumatic separator

- SBallistic separator

- Fe and ALU metal separator

- Cleaning chamber

- Chamber >300 mm fraction

- Balers

The legislation requirements relating to the level of recycling make it necessary to set up new sorting stations where they were not yet built or retrofit existing systems to reach the required level.

Zakład Gospodarki odpadami S.A. in Bielsko-Biała saw it for itself in 2016. The fire, which was created in the waste containers, covered a large part of the hall together with the whole infrastructure used for sorting waste. The millions lost are not the only cost of the tragedy. Timely municipal services for residents still had to be provided, and at the same time, the waste collected had to be properly managed. Tomasz Ficoń, a spokesman for the town hall, even said that this is a problem of a waste collection company, sorting station and the town hall. We can elaborate on that by saying:

- The sorting station will lose its profit because it will not be able to receive many waste fractions until the facility is rebuilt

- Additional costs will be borne by the waste collection companies, which have to transport the waste to sorting stations located further away

- Therefore, the cost of waste collection companies were probably renegotiated with the town hall, which also had to bear the costs of signing an agreement with a substitute sorting station that took over the burden of waste management from Bielsko-Biała

As can be seen, the effects of a fire at a waste sorting station do not only affect the owner of the system directly but also other companies and institutions.