Cryogenic grinding

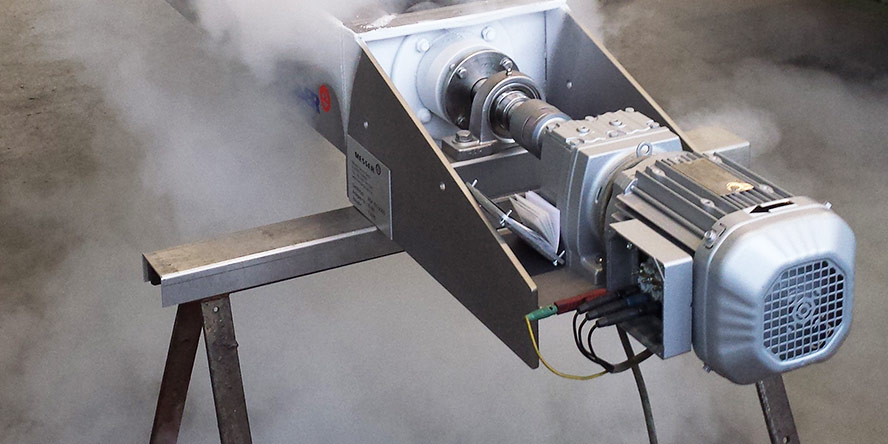

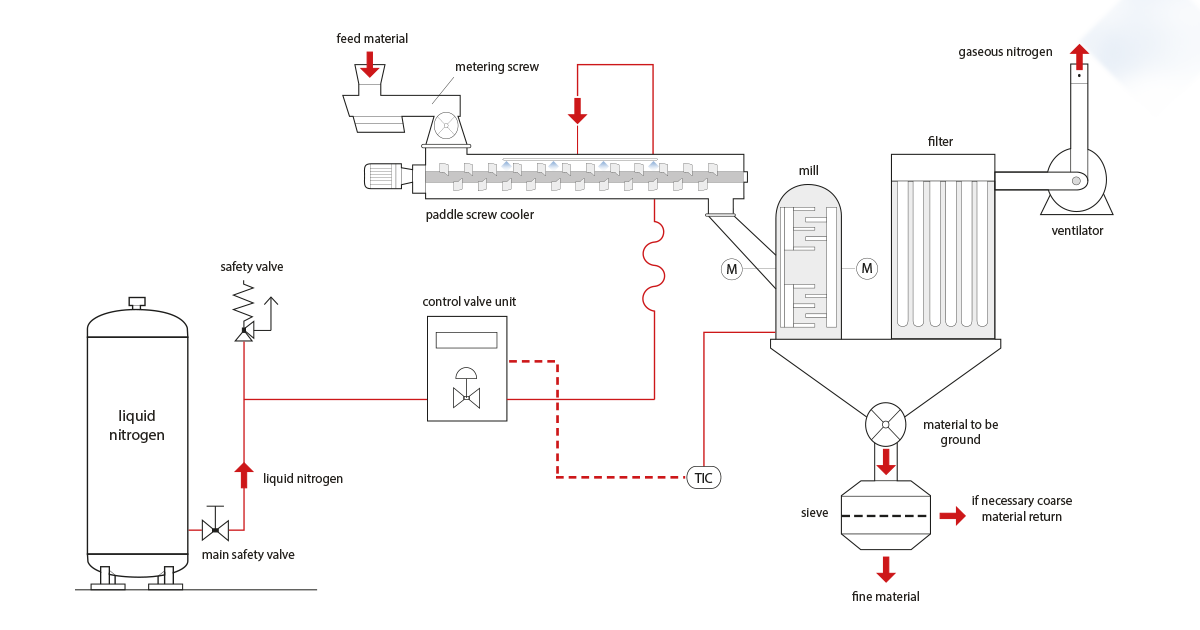

We manufacture complete cryogenic grinding lines, enabling efficient production of finer particles by using freezing of ground / milled material with liquid nitrogen or dry ice (solid CO2). Depending on the product properties such as strength, hardness, flexibility/plasticity and the desired particle size, the following grinding and pulverisation principles are applied: breaking, crushing, cutting, abrasion, impact.

Comprehensive work related to cryogenic grinding – from consulting on the application of technology, design of cryogenic grinding line and structural elements, to the selection of appropriate system components – is carried out in cooperation with MESSER Polska. This allows our customers to run cryogenic grinding tests in the MESSER R&D centre.

We will answer questions about: offer, technical specification, delivery, assembly.

- possibility of obtaining grains with particle sizes up to 50 µm after grinding

- grinding and pulverisation principles (breaking, crushing, cutting, abrasion, impact) are applied depending on the product properties such as strength, hardness, flexibility/plasticity and the desired particle size

- for particles smaller than 300 µm, mills with tested impact effect such as “peg mills” are suitable

Depending on the material, the following gases are used in the process:

- Nitrogen (liquefied)

- or CO2 (liquefied)

Cryogenic technology is used to grind/pulverise:

- food products and plant materials: herbs, spices, beans (e.g. coffee), dried fruit, etc.

- plastics, polymers, rubber,

- wax, paraffin wax, resins, paint pigments, etc.

Cryogenic grinding is applicable in:

- pharmaceutical industry

- rubber industry

- plastics industry

- food industry

- production of industrial mills

- recycling

- higher efficiency of the production process

- possibility of obtaining finer powders

- no thermal damage (e.g. when grinding pharmaceuticals)

- no oxidation damage (e.g. when grinding nuts)

- no evaporation of aromatic oils (e.g. when grinding spices)

- no fire or dust explosion hazard

- no clogging or blocking of the grinding elements

- consulting on the application of cryogenic grinding technology

- cryogenic grinding line design

- selection of system components

- design and supply of structural elements

- supply of the mill, cooling system, separators, dust extraction system, transport systems, final product receiving system and packing line