Separation of composite materials – cryogenic pulverisation

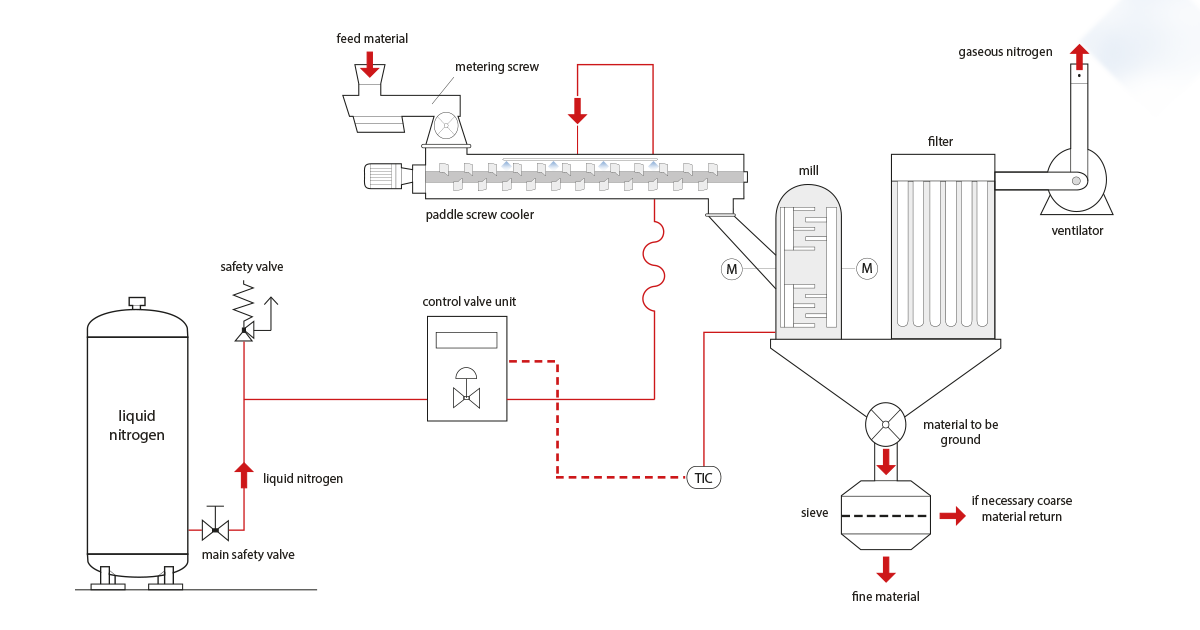

We manufacture complete product separation lines with the use of cryogenic technology. The cryogenic pulverisation method (or cryogenic separation) aims to increase the brittleness of the product with liquid nitrogen. It is used for breaking up composite materials such as used tyres, metallized plastic parts, car dashboards, electronic waste and used paint containers. Differences between the thermal expansion coefficients of different components cause breaking of bonds between materials, which then enables mechanical separation.

Projects in the field of industrial installations for cryogenic processing of products such as used tyres, roofing materials, floorings and PVC window frames are carried out in cooperation with MESSER Polska. In addition, our customers can run cryogenic grinding tests in the MESSER R&D centre.

We will answer questions about: offer, technical specification, delivery, assembly.

The cryogenic separation process takes place after the product has been ground (see cryogenic grinding), using a method appropriate for the combined material / composite. For example, after grinding braided garden hoses on screens, the “flocks” remaining from the polyester braid are screened out, while PVC powder “goes through” the screens. In the case of electronic printed circuit boards, the plastic goes through and the metals are separated on separators suitable for the specific metal type.

The size of the input material determines the type of coolant to be used. Most often, it is liquid nitrogen.

The cryogenic pulverisation method is used in:

- rubber processing industry

- plastics processing

- automotive industry

- recycling

- increased efficiency of existing recycling facilities

- environmentally friendly process

- reduced costs of waste disposal

- reduced costs associated with landfills and waste incineration, etc.

- low capital investments

- reliable and safe operation

- consulting on the application of cryogenic grinding and separation technology

- cryogenic grinding line design with cryogenic separation

- selection of system components

- design and supply of structural elements

- supply of the mill, cooling system, separators, dust extraction system, transport systems, final product receiving system and packing line