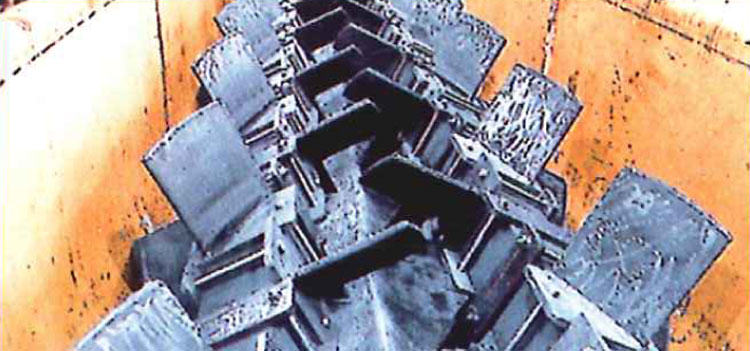

Pug mill

The twin-shaft “Pug Mill” screw granulator with a capacity of up to 250 t/h and a power of up to 132 kW is used for mixing and granulation processes. It can work in difficult conditions in the presence of urea, steam, sulphuric acid, ammonia.

We will answer questions about: offer, technical specification, delivery, assembly.

- Processes: mixing, granulation

- Possible operation in the presence of urea, water stream, sulphuric acid, ammonia, etc.

- Easily replaceable mixer paddles made of special steel coated with hard sealant

- Tubes and liquid injection nozzles made of stainless steel or Alloy 20

- Capacities up to 250 t/h, power up to 132 kW

- Selection of equipment with an accompanying system

- Tests with the Customer’s actual product

- Installation, commissioning, service

- Task implementation in the “turnkey” system