Combined roller and bowl type mills

We supply roller and bowl type mills or complete milling lines with a single unit capacity from 2 to 450 t/h. The milling lines include systems for transporting and feeding the product to the mill, weighing system, pneumatic system for receiving the milled product, dedusting and screening plants. The offered solutions are operated in hundreds of industrial plants throughout the world, in particular in the production of cement, clinker, ceramic semi-finished products, kaolin, bentonite, coal, coke, dolomite, talcum, anhydrite, calcite and limestone.

Vertical roller and bowl type mills are characterised by a number of advantages, including above all the capability of carrying out the process of milling, drying and separating in one device. The offered solution is additionally characterized by ease of changing the grain size of the milled product, low energy consumption, quick replacement of wearing parts, the ability to select the classifier to suit the specific process, low noise emission.

Contact our engineer

We will answer questions about: offer, technical specification, delivery, assembly.

Combined roller and bowl type mills – examples of installations

Vertical Roller and Bowl Type Mills – Basic Information

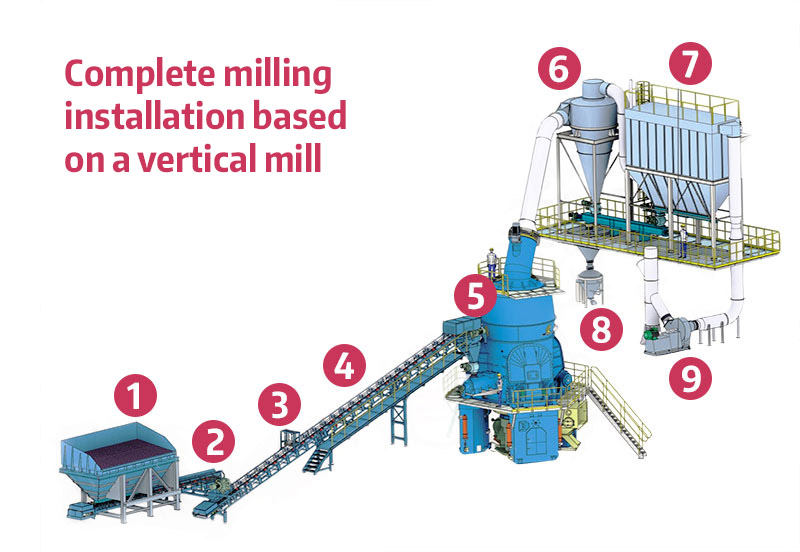

Depending on your needs, the scope of our activities may include the supply of a complete milling plant or only its heart in the form of a vertical roll and bowl type mill. Below is a example of a milling plant.

Example of milling plant

- Acceptance system

- Weighing system

- Magnetic separator

- Belt feeder

- Vertical (roller and bowl type) mill

- Cyclone

- Dust extractor

- Pneumatic transport

- Fan

Milling plants

We deliver both roller and bowl type mills, as well as complete milling plants consisting of a unit for accepting the product and feeding it to the mill, weighing unit, pneumatic system for receiving the milled product, and dust removal and screening plant.

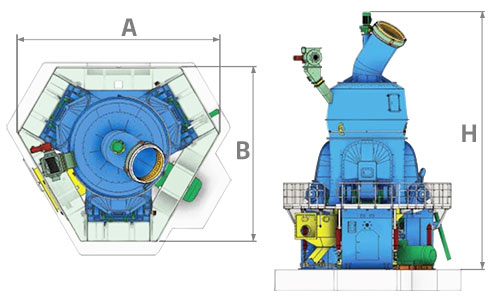

| Type | Bowl diameter | Number of milling elements | Capacity [t/h] | Mill motor output [kW] | Separator motor output [kW] | Weight [t] | A [m] | B [m] | H [m] |

|---|---|---|---|---|---|---|---|---|---|

| EVM 1200 | ᴓ 1200 | 2 | 10 | 132 | 11 | 34 | 2,92 | 2,45 | 7,2 |

| EVM 1600 | ᴓ 1600 | 2 | 25 | 250 | 15 | 65 | 4,23 | 4,92 | 8,3 |

| EVM 2000 | ᴓ 2000 | 2 | 40 | 400 | 22 | 93 | 3,5 | 3,6 | 10,5 |

| EVM 2600 | ᴓ 2600 | 3 | 60 | 710 | 30 | 208 | 6,8 | 6,4 | 12,0 |

| EVM 3000 | ᴓ 3000 | 3 | 95 | 1000 | 75 | 220 | 8,0 | 7,4 | 13,0 |

| EVM 3500 | ᴓ 3500 | 4 | 150 | 1500 | 110 | 250 | 8,5 | 8,0 | 14,0 |

| EVM 4000 | ᴓ 4000 | 4 | 200 | 2000 | 160 | 450 | 9,5 | 9,0 | 15,2 |

| EVM 4500 | ᴓ 4500 | 4 | 275 | 2500 | 180 | 530 | 10,5 | 9,5 | 16,0 |

| EVM 4800 | ᴓ 4800 | 4 | 320 | 3000 | 200 | 610 | 11,0 | 10,0 | 18,0 |

| EVM 5000 | ᴓ 5000 | 4 | 350 | 3500 | 250 | 660 | 21,0 | 11,0 | 19,0 |

| EVM 5300 | ᴓ 5300 | 3+3 | 400 | 4500 | 315 | 710 | 12,8 | 11,8 | 19,5 |

| EVM 5500 | ᴓ 5500 | 3+3 | 450 | 5000 | 355 | 750 | 13,5 | 12,5 | 20,0 |

Advantages of vertical (roller and bowl type) mills

- Milling, drying and separation in one machine

- Low energy consumption

- Easily change the grain size of the product after milling

- Quick replacement of wearing parts

- Possibility to select a separator according to the nature of the process

- Low noise emission

Vertical roller and bowl type mills – application

Mills of this type are mainly intended for milling products of natural origin. However, they can also be used for less typical applications, such as glass cullet. Their capacity ranges from a few tonnes of product per hour to 450 t/h.

Application of vertical mills by industries:

- mineral and ore purification industry

- cement industry

- energy industry

- building materials industry

Application of impact mills by products:

- limestone

- ceramic semi-finished products

- slag

- coal and coke

- bentonite

- colemanite

- anhydrite

- kaolin

- cement

- talcum

- calcite

- dolomite

- coal and biomass