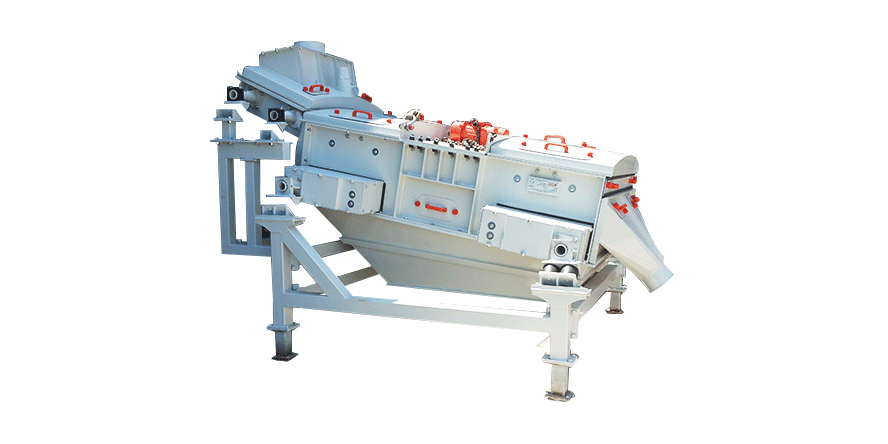

Dewatering screening machines

We deliver dewatering screening machines for products with granulation up to 30 mm, which are characterised by both loose and tight, silty, and even loamy structure.

The device is equipped with a drive in the form of two counter rotating, unbalanced, low power vibrating motors mounted directly on the screening machine, as well as with VFE® (Vibro-Flex Exciter) elastomer actuators that cause an uncoordinated movement of screens. This solution enables the device to achieve exceptionally low end humidity of the material while consuming exceptionally low energy.

Dewatering screening machine is perfect for dewatering of suspensions, separating of solid fractions, and wet screening of fine-grained fractions, including loamy and silty fractions.

We will answer questions about: offer, technical specification, delivery, assembly.

Dewatering screening machines – samples of applications

The most important advantages

- Effective dewatering of product

- Possibility to use polyurethane screening cloth with mesh up to 18 µm

- No screen clogging effect

- Low energy consumption

- Simple operation and maintenance

- No transfer of vibrations to the support structure

Very quick and easy assembly of screening cloths without any necessity of tensioning

Dewatering screening machines – basic information

- Drive with the use of two counter rotating, unbalanced, low power vibrating motors (machine body vibrates with amplitude of 0.5-1 m) mounted directly on the screening machine

- The movement of screening cloths has an uncoordinated nature, chaotic frequency, which reach a local vibration amplitude at the level of 3-6 mm and high accelerations that give the screen self-cleaning properties (warranty of constant cleaning of screening cloths)

- Possibility to mount rinsing jets at the inlet part of the screen

- Exceptionally high product filtering accuracy thanks to uncoordinated vibrations with high vibration frequency at very low engine power

- Exceptionally low energy consumption

- No dynamic loads transferred to the structure of hall

- Simple operation and maintenance (possibility of very quick replacement of screening cloth)

Dewatering screening machines – application

In numerous industries, products require earlier dewatering before the next production process. Proposed screening machines ensure a high capacity in dewatering fine-grained and medium-grained products. They are perfect for, among other things, recovering powder from rinsing water and dewatering gravel or fine-grained sand.

Application of dewatering screening machines according to industries:

- food industry

- mineral industry

- building materials industry

- energy industry

Application of dewatering screening machines according to products

- fine coal

- fine-grained sand at 50 μm

- aggregates

- building and demolition wastes

- iron and metal ore

Depending on your needs, we can deliver dewatering screening machine, as well as a complete line for screening your products.

- Project of screening line

- Selection of a correct dewatering screening machine

- Assembly and start-up

- Service of dewatering screening machine