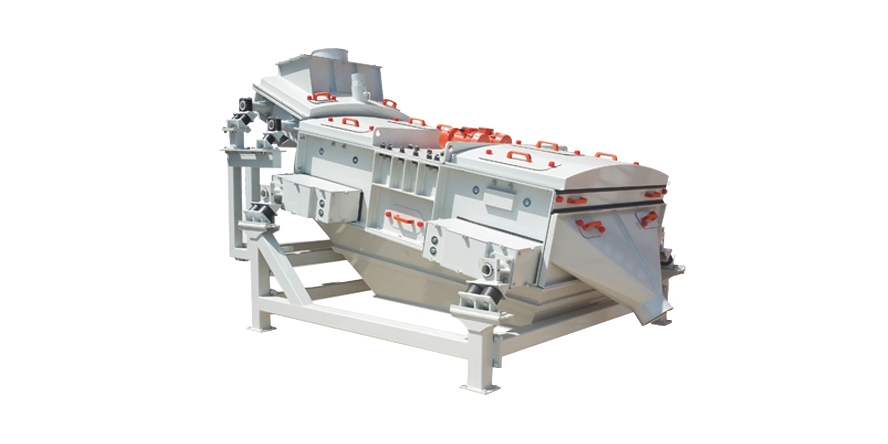

Screening machines for fine-grained products and medium-grained products

We deliver both screening installations and autonomous screening machines for loose and wet products with granulation up to 30 mm. Thanks to the patented VFE® (Vibro-Flex Exciter) actuators, the screening cloth vibrates with chaotic frequency, which translates into a series of quite significant advantages. To the most important advantages of our products belong exceptionally high quality of screening wet and very fined-grained products with fraction of 200 µm that have a tendency to screen clogging effect (possibility to separate the product even at the cut point of 36 µm).

Screening machines are available in various sizes with capacity up to approximately 100 t/h. The performance can be increased by placing several devices installed together. Screening machine execution with several screen decks can be used to screen several fractions at the same time. Although the device’s operation is similar to average screening machines, its principle of operation differs in a significant way. Benefits of this system are i.a. significantly smaller energy consumption, no clogging effect and lack of transfer of dynamic loads to the structure of a hall.

We will answer questions about: offer, technical specification, delivery, assembly.

Screening machines for fine-grained products and medium-grained products – samples of applications

The most important advantages

- Possibility to screen of wet products and very fine-grained fractions of 50-200 µm

- No screen clogging effect, self-cleaning properties

- Low energy consumption

- Simple operation and maintenance

- No transfer of vibrations to the support structure

- Assembly doesn’t require any complicated works

- Very quick and easy assembly of screening cloths without any necessity of tensioning

Screening machines for fine-grained products and medium-grained products – basic information

- Application of two counter rotating, unbalanced mass, low power vibrating motors in combination with the patented VFE® elastomer actuators result in the chaotic vibration frequency of screening cloth

- Loose mounting of the screening cloth, which reaches a local amplitude of 3-6 mm and high accelerations as a result of chaotic vibrations (thanks to special actuators) that in turn influences the self-cleaning properties of the screen and ensures a constant cleaning of screen cloths (prevents the screen clogging effect)

- Exceptionally high product screening accuracy thanks to uncoordinated vibrations with high vibration frequency at very low engine power – this cannot be achieved on other types of screens without the use of expensive systems supporting screening and cloth cleaning (e.g. ultrasonic)

- Exceptionally low energy consumption

- No dynamic loads transferred to the structure of hall

- Possibility to screen both dry and wet products

- Simple service and operation (possibility of very quick replacement of screen’s cloth)

- Application of simple vibrating distribution feeder on the screen’s inlet guarantees an equal and uniform distribution of product on the screening surface

- Completely dustproof

- Possibility to build several devices together in order to increase capacity

- Possibility to build several screening desks in order to screen several fractions simultaneously

- Delivery of a complete screening installation along with reception, storage, product feed to the screen, transport, and dedusting systems

- Execution in the EX version (engines, earthing) to zone 22 of the ATEX Directive

- Execution intended for food industry

Screening machines – application

Screening machines are intended for separation of dry and wet products with granulation up to 30 mm. The devices can be easily adjusted to screen very fine-grained fractions (50-200 µm). The screens are produced in various sizes with capacity up to 100 t/h. The capacity can be increased by placing several devices installed together. Screening machines are perfect for screening of both dry and wet products that have a tendency to screen clogging effect.

Application of screening machines according to industries:

- food industry

- mineral industry

- building materials industry

- paint production

- fertiliser production

- energy industry

- recycling (small fractions)

Application of screening machines according to products:

- sugar (including dust removal)

- salt

- limestone flour

- gypsum

- quartz sand

- feldspar

- dry clay

- cement

- dry plasterwork

- fillings for structural joint fillers

- paint pigments

- calcite

- pearlite

- wet clay, wet coal, wet sand

Depending on your needs, we can deliver only the screening machine, as well as a complete line for screening loose products. If necessary, we also protect the installation against an explosion of dust.

- Project of screening line

- Selection of a correct screening machine

- Assembly and start-up

- Service of screening machine