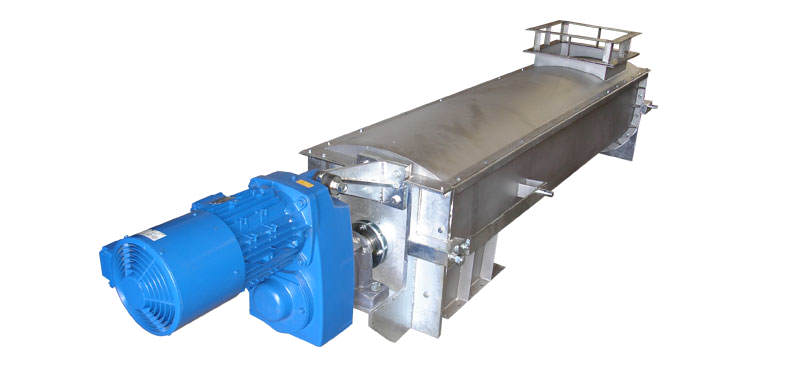

Screw conveyors (screw feeders)

The screw conveyors, screw feeders offered by the WOLFF GROUP can operate in the explosion hazard zone – ATEX. They are adapted to work in food, chemical, energy and building materials industries.

We will answer questions about: offer, technical specification, delivery, assembly.

- possibility to operate in a potentially explosive atmosphere – ATEX

- adapted to work in food, chemical, energy and building materials industries

- bent metal trough (U-shaped trough cross-section)

- tubular trough (O-shaped trough cross-section)

- easy-to-clean, smooth internal feeder surface

- shape of the feeder inlet/outlet adapted to the customer’s needs

- material make adapted to performance and product characteristics

- making the necessary calculations (capacity, power requirement, dimensions)

- production of customized screw conveyors (own or customer design)

- manufacture of support structures for screw feeders

- mechanical and electrical installation of screw feeders

- control of screw feeders

- stainless steel

- black steel

- mixed technique:

- stainless steel body

- shaft made of black steel plated with stainless steel (increased mechanical resistance of shafts to torsion)

- screw galvanized and plated with stainless steel sheet (reduction of manufacturing costs)

- NORD gear motor – standard solution

- on customer’s request, the possibility of using a drive from another manufacturer