Tubular drag (aero-mechanical) conveyor

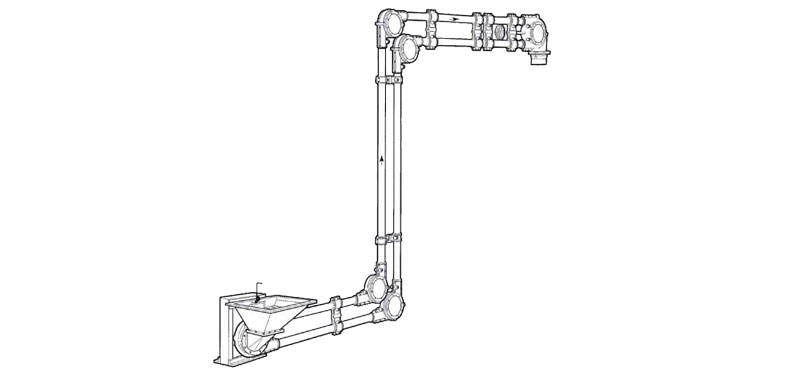

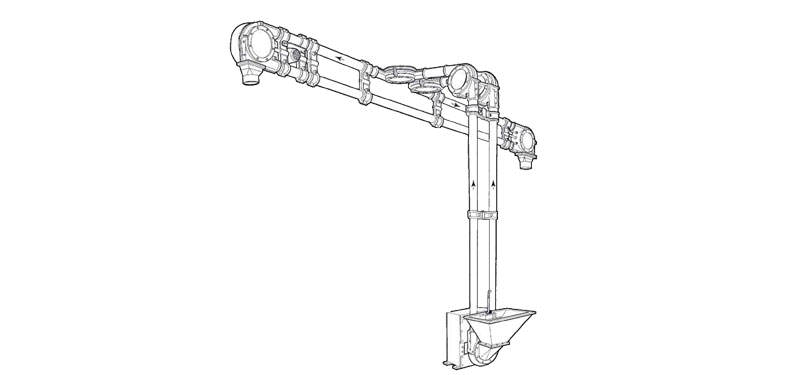

The tubular drag conveyor consists of a tube with a line with (plastic) disks set on it moving inside the tube. The disks are not tightly fitted in the tube; they move with a relatively high linear speed and set in motion the material and the air inside the transporter. This results in fluidization of the transported product ensuring its delicate transport in conditions similar to pneumatic transport. The advantage of the conveyor is a high efficiency of transport, no need to adjust dust removal and a small area required for conveyor installation.

We will answer questions about: offer, technical specification, delivery, assembly.

- Tubular drag conveyor 3”

With tubes 75 mm in diameter and a maximum capacity of 15 m3/h - Tubular drag conveyor 4”

With tubes 100 mm in diameter and a maximum capacity of 30 m3/h

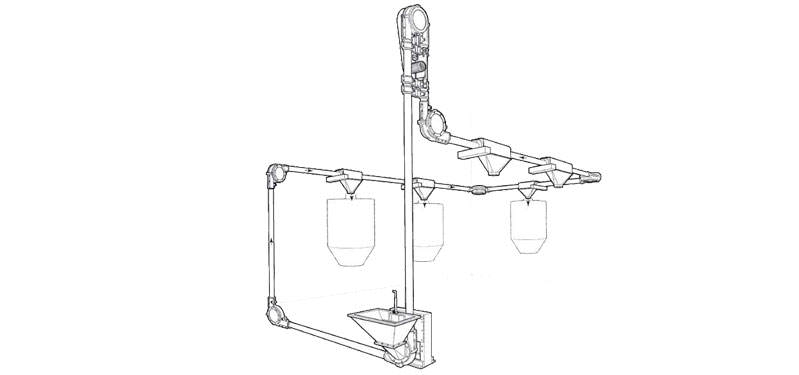

- Free configuration of vertical, horizontal and slanting segments of the conveyor

- Charge to the conveyor from many supply sources

- Distribution and dosage of material independently to many collection points

- Compressed air cleaning system

- Selection of design materials proper for the transported material

- Design for operation in an explosion risk zone (Ex)

- Transport of delicate powders and granulated products

- Transport in the food industry of sugar, flour, coffee, tea, powdered milk

- Transport of sodium, potassium, fluorine, aluminium, limestone, soot, PVC

- Design and selection of a proper conveyor

- Installation, commissioning and service of the conveyor

- Turnkey project