Flame Arresters

Wherever inflammable liquids are stored or inflammable mixtures of gases or vapours of products with the air are generated, safeguards must be applied in the form of flame breakers which, in case of ignition occurrence and flame spreading, eliminate the risk of a serious industrial disaster and protect the human life.

GRUPA WOLFF is a supplier of flame breaker suitable for application in chemical, petrochemical, and mining industries, as well as at transport and storage of various products generating explosive atmospheres. Our additional asset is the capacity to install and service the equipment supplied, as well as implementation of complex tasks consisting in a delivery and erection of pipelines.

We will answer questions about: offer, technical specification, delivery, assembly.

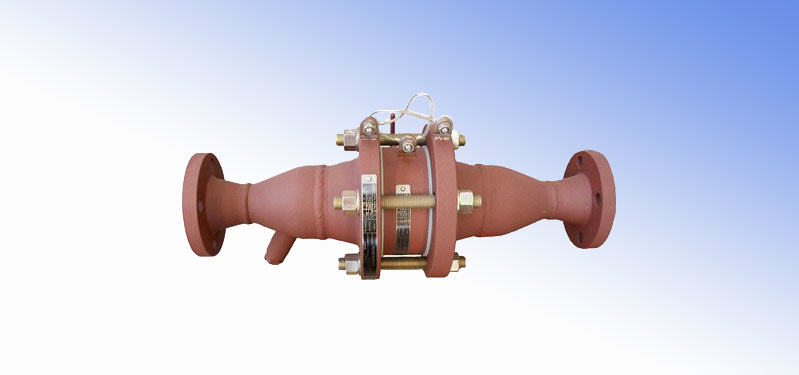

1. TUBULAR TWO-WAY FLAME BREAKERS FOR INFLAMMABLE GASES AND LIQUIDS

(Unstable) detonation:

In case of a flame and a pressure wave moving about with a supersonic speed.

Deflagration:

In case of a flame moving about with a supersonic speed.

- Making necessary calculation

- Selection and delivery of a proper solution

- Installation and service

A flame breaker is a passive anti-explosive safeguard which does not contain any movable elements. The key element of flame breakers is a flame-suppressing insert.

The flame-suppressing insert consists of a metal casing containing a matrix of triangular openings with guaranteed uniformity. It is extremely important since all gases occurring in industry are characterised by the parameter called the Maximum Experimental Safe Gap (MESG), i.e. the gap which a flame is not able to get through.

When an ignition of mixtures of gases or vapours of inflammable liquids occur, the suppressing element prevents a further spreading of the flame through absorbing and dispersing the head of the burning mixture. The moment a flame gets inside the breaker, the process begins of gradual decreasing of temperature of the burning substance to the level at which self-ignition of the substance is no longer possible.

In case of flame breakers, technical parameters are chosen individually for the particular application. In order to select a proper protection, please contact with the engineer responsible for this group of products. You will find the engineer’s particulars on the right-hand side or in the CONTACT tab.

GRUPA WOLFF offers a broad assortment of accessories for flame breakers:

- Heating jackets

- Temperature sensors

- Test and measuring connections

- Connections for endoscopic tests

- Differential pressure elements

- Steam and water cleaning systems

- Outlets

GRUPA WOLFF is able to deliver proper solutions to all applications related to transport and storage of inflammable liquids and gases. Below are examples of typical application areas:

- Thermal afterburning

- Vapour hermetic sealing plants

- Oil and gas reloading terminals

- Overpressure storage tanks

- Chemical and petrochemical plants

- Mining platforms and oil and gas mines

- Combustion motors

- Gas analysers, calorimeters

- Solid fuel mines

- Vacuum pumps

- Fans and blowers

- Waste treatment plants

- Biofuel plants

The flame breakers are manufactured as per ISO 9001:2008; they are also certified in conformity with directive ATEX 94/9/EC.

Moreover, flame breakers are designed, tested and certified by the EN ISO 16852 standard in compliance with the requirements of Directive ATEX 94/9/EC and have certificates issued by the following notified bodies: BS 7244:1990, USCG, IMO, FTZU, PTB, BAM, CSA, HSE, INERIS, GOST-R and NEMCO. Flame breakers also meet the requirements of Directive PEX 97/23/EC.

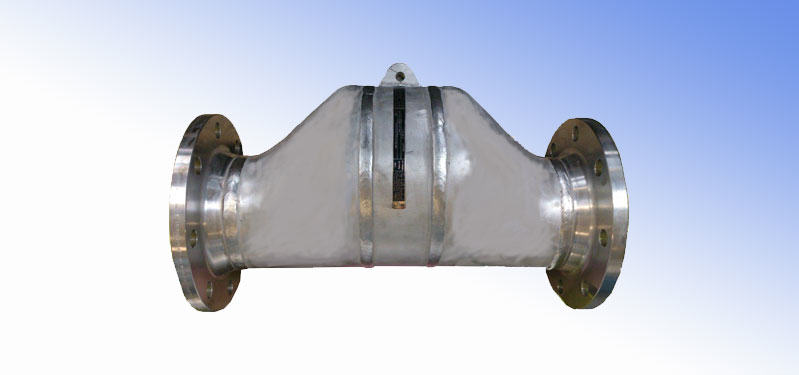

2. TUBULAR TWO-WAY FLAME BREAKERS FOR LIQUIDS

Detonation:

In case of application on pipelines filling and emptying storage tanks for inflammable liquids.

Atmospheric deflagration during an inspiration/expiration:

A broad scope of over- and underpressure breathing valves intended for operation in tandem with AMAL flame breakers preventing flames from getting inside the tank.

- Making necessary calculation

- Selection and delivery of a proper solution

- Installation and service

A flame breaker is a passive anti-explosive safeguard which does not contain any movable elements. The essence of successful operation of flame breakers is construction of the flame-suppressing element.

The flame-suppressing element consists of a metal casing containing a matrix of triangular openings with guaranteed uniformity. All gases found in industry are characterised by a strictly specified gap which a flame will not get through. It is called the Maximum Experimental Safe Gap, in short: MESG.

When an ignition of mixtures of gases or vapours of inflammable liquids occur, the flame suppressing element prevents a further spreading of the flame through absorbing and dispersing the head of the burning mixture, beginning from the breaker nozzle where the burning has started. As soon as the flame enters the inside of openings of the suppressing element, the process begins of gradual decreasing of temperature of the burning substance to the level at which self-ignition of the substance is no longer possible.

In case of flame breakers, technical parameters are chosen individually for the particular application. In order to select a proper protection, please contact with the engineer responsible for this group of products. You will find the engineer’s particulars on the right-hand side or in the CONTACT tab.

GRUPA WOLFF offers a broad assortment of accessories for flame breakers:

- Heating jackets

- Temperature sensors

- Test and measuring connections

- Connections for endoscopic tests

- Differential pressure elements

- Steam and water cleaning systems

- Outlets

GRUPA WOLFF is able to deliver proper solutions to all applications related to transport and storage of inflammable liquids and gases. Below are examples of typical application areas:

- Thermal afterburning

- Vapour hermetic sealing plants

- Oil and gas reloading terminals

- Overpressure storage tanks

- Chemical and petrochemical plants

- Mining platforms and oil and gas mines

- Combustion motors

- Gas analysers, calorimeters

- Solid fuel mines

- Vacuum pumps

- Fans and blowers

- Waste treatment plants

- Biofuel plants

The flame breakers are manufactured as per ISO 9001:2008; they are also certified in conformity with directive ATEX 94/9/EC.

Moreover, flame breakers are designed, tested and certified by the EN ISO 16852 standard in compliance with the requirements of Directive ATEX 94/9/EC and have certificates issued by the following notified bodies: BS 7244:1990, USCG, IMO, FTZU, PTB, BAM, CSA, HSE, INERIS, GOST-R and NEMCO. Flame breakers also meet the requirements of Directive PEX 97/23/EC.

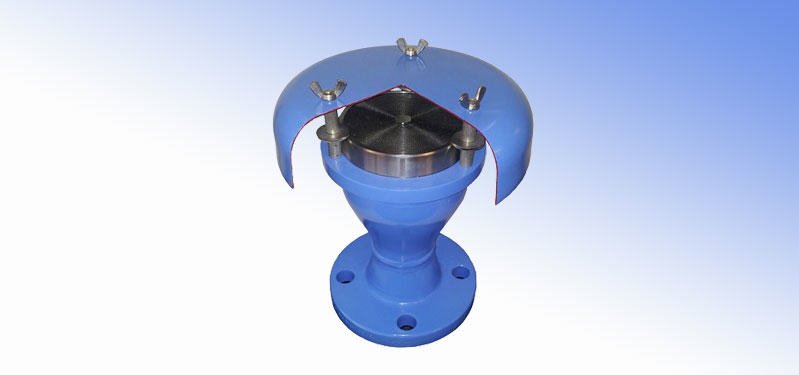

3. END FLAME BREAKERS

Deflagration:

In case of a flame moving about with a supersonic speed.

They are also available in the version protecting against lengthy burning.

- Making necessary calculation

- Selection and delivery of a proper solution

- Installation and service

A flame breaker is a passive anti-explosive safeguard which does not contain any movable elements. The essence of successful operation of flame breakers is construction of the flame-suppressing element.

The flame-suppressing element consists of a metal casing containing a matrix of triangular openings with guaranteed uniformity. All gases found in industry are characterised by a strictly specified gap which a flame will not get through. It is called the Maximum Experimental Safe Gap, in short: MESG.

When an ignition of mixtures of gases or vapours of inflammable liquids occur, the flame suppressing element prevents a further spreading of the flame through absorbing and dispersing the head of the burning mixture, beginning from the breaker nozzle where the burning has started. As soon as the flame enters the inside of openings of the suppressing element, the process begins of gradual decreasing of temperature of the burning substance to the level at which self-ignition of the substance is no longer possible.

In case of flame breakers, technical parameters are chosen individually for the particular application. In order to select a proper protection, please contact with the engineer responsible for this group of products. You will find the engineer’s particulars on the right-hand side or in the CONTACT tab.

GRUPA WOLFF offers a broad assortment of accessories for flame breakers:

- Heating jackets

- Temperature sensors

- Test and measuring connections

- Connections for endoscopic tests

- Differential pressure elements

- Steam and water cleaning systems

- Outlets

GRUPA WOLFF is able to deliver proper solutions to all applications related to transport and storage of inflammable liquids and gases. Below are examples of typical application areas:

- Thermal afterburning

- Vapour hermetic sealing plants

- Oil and gas reloading terminals

- Overpressure storage tanks

- Chemical and petrochemical plants

- Mining platforms and oil and gas mines

- Combustion motors

- Gas analysers, calorimeters

- Solid fuel mines

- Vacuum pumps

- Fans and blowers

- Waste treatment plants

- Biofuel plants

The flame breakers are manufactured as per ISO 9001:2008; they are also certified in conformity with directive ATEX 94/9/EC.

Moreover, flame breakers are designed, tested and certified by the EN ISO 16852 standard in compliance with the requirements of Directive ATEX 94/9/EC and have certificates issued by the following notified bodies: BS 7244:1990, USCG, IMO, FTZU, PTB, BAM, CSA, HSE, INERIS, GOST-R and NEMCO. Flame breakers also meet the requirements of Directive PEX 97/23/EC.