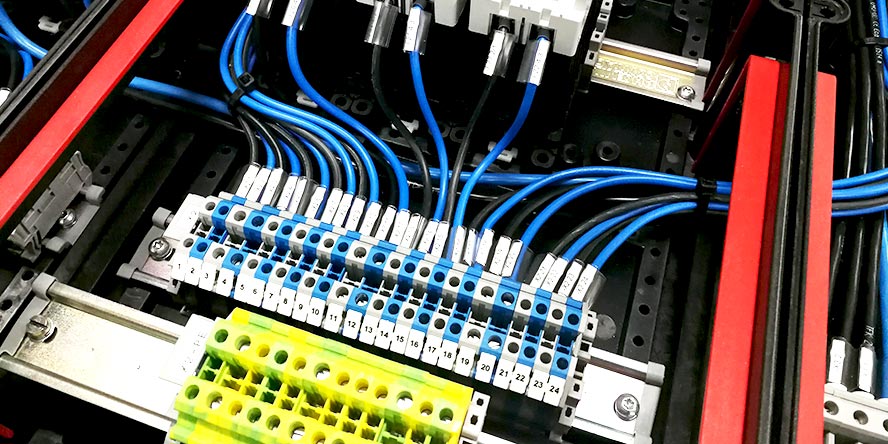

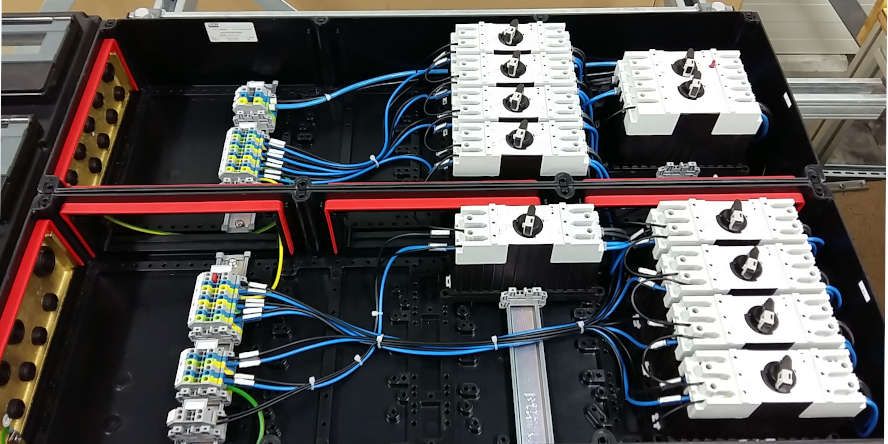

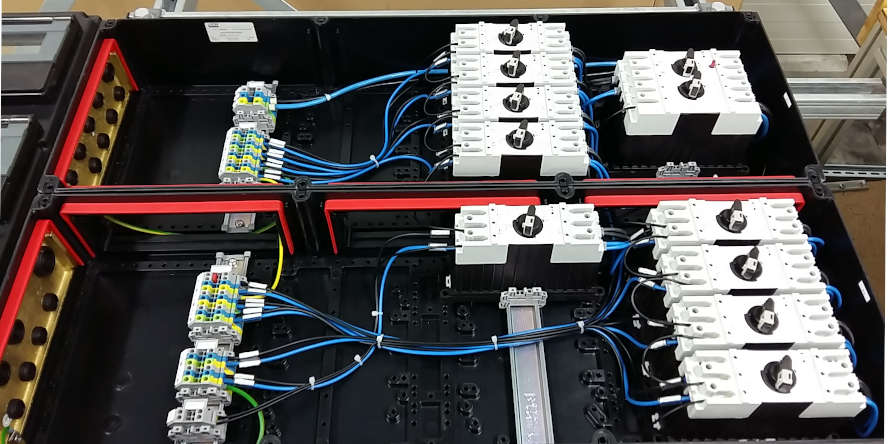

Own prefabrication of EX control panels, boxes and energy distribution switchboards

Key advantages

Guaranteed high quality due to total control over the product at each stage of the manufacturing process

Quick implementation due to shorter lead times for non-standard solutions

Possibility of manufacturing small amounts even within 1–3 business days from order acceptance

What do we do?

Scheme design, prefabrication of equipment for operation in hazardous areas and their subsequent installation on the site is our specialty. Below you will find a detailed list of control stations, boxes and switchgear we make.

HARDO

| Type | Code type |

|---|---|

| Terminal boxes GRP | HTB1P |

| Aluminum terminal boxes | HTB1A |

| Stainless steel terminal boxes | HTB1S |

| Control stations GRP | HCS1P |

| Aluminum control stations | HCS1A |

| Stainless steel control stations | HCS1S |

| Type | Description |

|---|---|

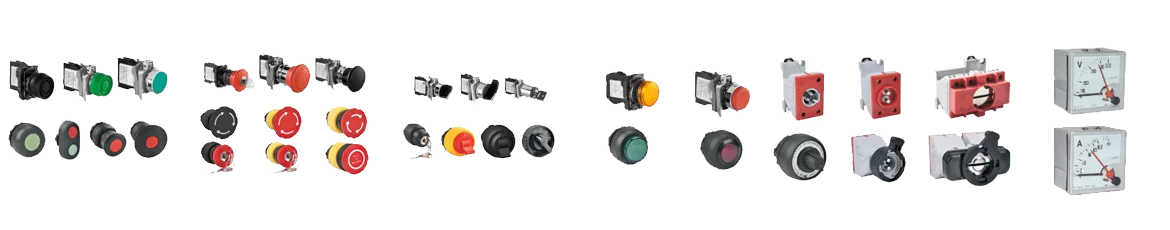

| Push Buttons | Spring-return pushbutton units and spring-return double pushbuttons can be combined with various types of contact modules in order to provide many different combinations of NO and NC contacts. These units are available in different colours and, as an option, may be fitted with various marking labels. |

| Emergency Mushroom Head Pushbuttons | Spring return mushroom head pushbutton units, complete with one electrical contact module. Push-pull emergency mushroom head pushbutton units (with or without key extraction), complete with one electrical contact module. Turn-to-release emergency mushroom head pushbutton units complete with one electrical contact module. |

| Selector Switches | Stay-put or spring return key selector units complete with one electrical contact module. |

| Signal Lamps | Signal lamps approved for use in hazardous areas. They come complete with an LED unit designed for different voltages as per electrical circuit requirements. Signal lamps are available in different colors. |

| Signal Lamps with Button | Spring-return illuminated push button unit. Complete with LED unit, available in different voltages and with one electrical contact. Available with different combinations of NO and NC contacts. Available in different colours. |

| Potentiometers | Potentiometer unit with range of resistance values. The knob is provided with a large visual display. |

| Voltmeters, Ammeters, Miliammeters | The HVA (Harmonic Voltage Analysis) Voltmeter, Ammeter, Miliammeter units are available with a large number of measuring range options, scaled 2 or 5 times. The ammeter unit can make a direct measurement or be used in conjunction with current transformers and upon request, secondary current transformers. The ammeter has a working temperature range from -40°C to +60°C |

| Switch module 2 – Pole | Two separate pressing rods controlling a group of contacts each. One group or two groups of contacts can be controlled by different operation heads to have different functions. |

| Switch module 4 – Pole | Two separate metal pressing elements, controlling two group of contacts each. Two groups or four groups of contacts can be controlled by different operation heads to have different functions. |

| Protective Window | Pilot light window of thermoresistant glass sealed with auto-leveling silicone. |

| Circuit breakers | Circuit breakers are devices that shut off power flow when a short circuit occurs. They are designed to protect people in potentially explosive atmospheres and can be used with currents of 6, 10, 16, 20, 25, 32 or 40 amps, with residual currents of 10, 30, 100 and 300 milliamps. |

| Contactors Rated voltage 24 V / 240 V | Contactors are compact components for Ex e enclosures in zones 1 and 2, and are durable and reliable for use in hazardous areas. All are easy to install, rugged and corrosion-resistant. The contactors are mounted in Ex e protected enclosures and can be used for a wide variety of applications. |

| Load Isolation Switches with Handle for currents up to 180 A | Load isolation switch module is certified and must be installed in an increased safety “Ex e” enclosure. It has good flame retardant performance and fast connect or breaking once the spring is tight to release. Wire terminals’ screws are made of stainless steel. |

EATON Crouse-Hinds (CEAG)

| Device type | Model |

|---|---|

| GRP terminal boxes (Level 1) | GHG72, GHG73, GHG74, GHG79 |

| Stainless steel terminal boxes (Level 1) | N-TB, Ex-CELL, S-TB |

| Stainless steel control boxes (Level 1) | GHG 414, GHG 414 81, GHG 414 82 |

| GRP control boxes (Level 1) | GHG 41, GHG 411 81, GHG 411 82, GHG 411 83, GHG 43, GHG 432, GHG 434 |

| GRP and stainless steel control panels (Level 2) – planned by the end of 2017 | GHG 44x, GHG 444 23, GHG 448 23, GHG 449 23, GHG 447 23, GHG 444 33, GHG 448 33, GHG 449 33, GHG 447 33 |

| Energy distribution switchboards (Level 3) | GHG619 |

We guarantee the highest quality

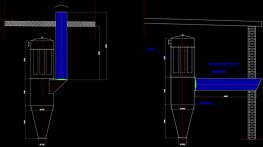

Currently, the production includes equipment made of thermoplastic, impact-resistant materials, fibreglass-reinforced polyester or stainless steel resistant to aggressive chemicals. The control boxes will be equipped with various configurations of buttons, control lights, connectors, etc. and the intermediate boxes will be equipped with various types of cable glands and terminals. The high flexibility of the equipment of control boxes and terminal boxes together with the wide range of accessories will enable us to respond to the individual requirements of our customers. Due to the fact that the production process is carried out in Balice, near Krakow, we can quickly develop dedicated applications, while all modifications and extensions of the system can be provided internally.

In the production process, we use certified components which enable easy parts replacement during service or modification works and during system extension with additional elements. The production is based on a modular construction of enclosures with wall mounting or dedicated stands which enable joining them into large switching systems. The production process follows the technical specifications of the customer.

Development plans

In the next stage, we plan to start the production of control boxes with larger dimensions and more extensive equipment. Broadening our range of products will enable us to implement complex control algorithms for various devices. Our plans also assume the production of switchboards intended for operation in potentially explosive atmospheres. These switchboards will be used to distribute electric energy in demanding industrial environments. Individual equipment for switching bays will enable us to meet any requirements of our customers. All our switchboards intended for use in potentially explosive atmospheres will be manufactured and tested in accordance with the highest standards to guarantee high level of safety. The switchboards will be prefabricated in accordance with the scheme developed and supplied by the customer or by the WOLFF GROUP’s design office, taking into account all conditions affecting the safety of their operation. This pertains in particular to the requirements regarding mechanical strength and resistance to temperatures.

Due to local prefabrication, we will be able to design switchboards for potentially explosive atmospheres in such a way that the power losses of installed electrical devices and components do not exceed the maximum enclosure surface temperature which, in the case of gas mixtures, is specified for the given temperature class.

Thanks to the special service flaps installed individually at our plant, integrated with the Ex-e enclosure, the installed modular devices can be started without the need to open the enclosure. The enclosures for switchboards will be made of fibreglass-reinforced polyester and intended for gas groups IIB and IIC, approved for use in explosion hazard zones 1 and 2 as well as 21 and 22.

International CAP programme

CAP (Certified Assembly Partner) is a special training programme for local production plants maintained by the authorised distributors in a specific country, used as a part of the quality assurance system. This programme is intended to manufacture explosion-proof electrical equipment based on the specialised knowledge and the engineering design documentation from the manufacturer, in accordance with the ATEX scheme as well as the specifications and requirements of the customer, using unified production procedures, evaluation criteria, testing methodology and reporting principles.

Broad scope of supply

We supply explosion-proof electrical equipment,

including: lighting fixtures, safety lighting fixtures, switchboards, control boxes and panels, connection equipment, safety circuit breakers.

Our operation in this area is comprehensive, i.e. from industrial plant audits, through the selection of appropriate solutions to their installation.