Problem:

- A tea manufacturer has introduced flavoured products

- Their ignition temperature was found to be lower than that generated by tea bag sealing machines

- This resulted in small incipient fires starting locally in the machine

- The dust collection system would drag the glowing particles into the filters, which in turn triggered the explosion protection system

Solution:

- A major protection system for combustible dusts, an explosion protection system is a last resort when preventive measures fail

- But reducing the frequency of its triggering will require the number of ignition sources to be lowered

- In this case, the most frequent ignition source were glowing particles, so, together with the Client, we decided to install spark detection and extinguishing systems on the four dust collection lines

Check the solutions used:

Explosive Tea Dust

Tea dust, like many other foods, is flammable and explosive. This is a well-known problem for one of our Clients, who has taken a number of measures to bring the risk of explosion and possible fire to a minimum. Client’s plant system could definitely be described as safe. This was the case until the decision to introduce flavoured teas to production. Then the situation changed dramatically.

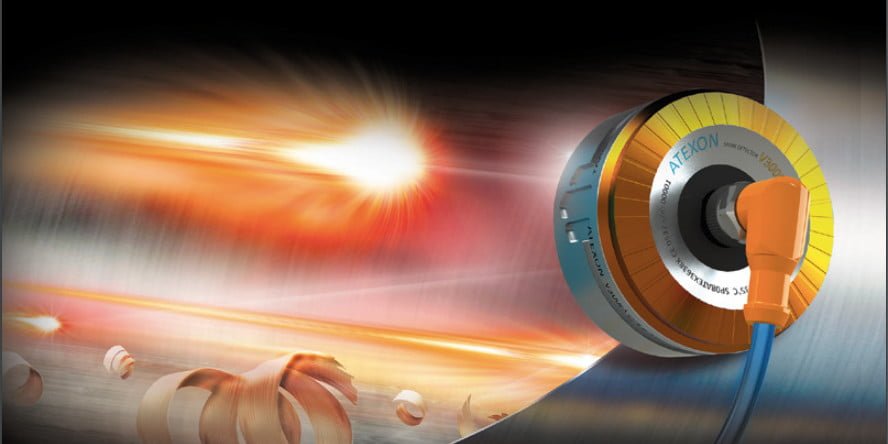

Dust Explosion in a Filter and the Operational Principle of the Spark Detection and Extinguishing System.

New Raw Material, New Problem

The ignition temperature of tea dust saturated with essential oils was found to be only 70°C. That was less than the temperature of the jaws designed to seal the tea bags. However, as long as the system was working properly, the air movement would cool the machine parts effectively, which minimised the risk of ignition. The problem, however, is that these types of systems require frequent downtime for their setting adjustment. Ignition was common on such occasions.

These small, incipient fires started locally would not have posed much of a threat if it were not for the fact that the packaging and sealing plant was connected to four dust extraction lines. Upon ignition, the glowing tea and tea bag parts were dragged into the dust collection filters and triggered the explosion protection system.

Explosion protection for dust collection systems

In the plant in question, all systems that collect tea dust from packaging and sealing machines were protected from the effects of an explosion by explosion suppression and isolation systems.

The first of them is designed to detect an explosion origin in the dust collection filter and then suppress it at a very early stage. For this purpose, rapid fire extinguishers are used, as their reaction time, from explosion detection to suppression, is counted in milliseconds. One can say that it takes more or less every one or two blinks of an eye.

Explosion containment, in turn, is to isolate a device in which dust exploded from the rest of the system in order to reduce the risk of so-called secondary explosions.

Limiting Ignition Sources

According to the ATEX directive, explosion protection should first prevent any possibility that an explosive atmosphere as well as possible ignition sources will be formed.

In our case, the implementation of a new raw material with a significantly lower ignition temperature forced us to consider new possible ignition sources, and then evaluate methods to reduce the frequency of their occurrence. This was the approach that our engineers used in that task: having analysed the problem, they selected spark detection and extinguishing technology as the most optimised solution that would not only increase operational safety but also reduce plant downtime.

As a result, we fitted sensors and water nozzles on each of the four tea dust extraction ducts. The system was designed to detect sparks and extinguish them by injecting a small amount of water into the ducts. The whole system was connected to the control panel.

The job was done in 3 days.