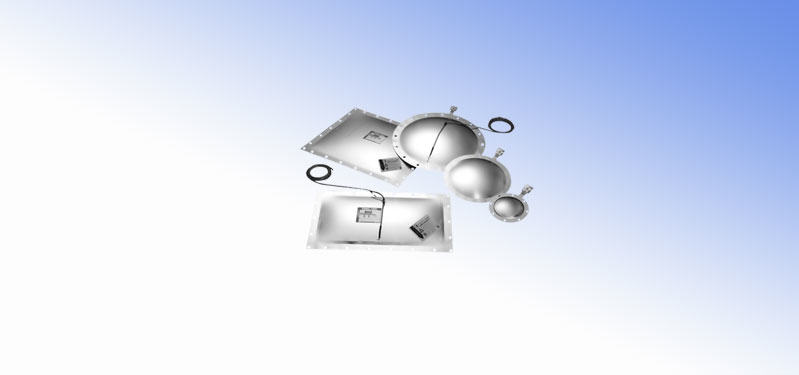

SAFETY PLATES FOR LOW, MEDIUM AND HIGH OPERATING PRESSURES

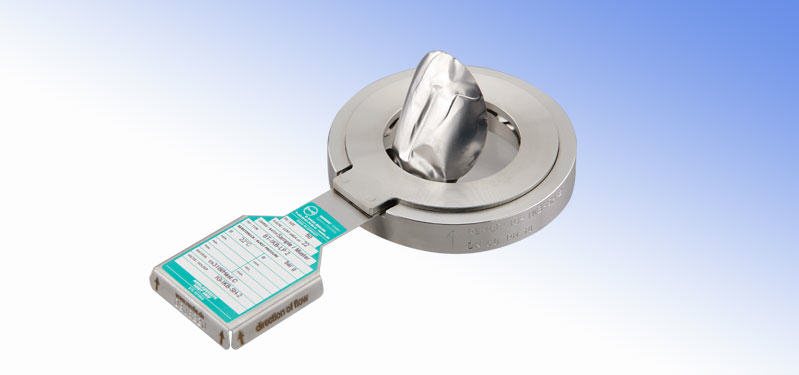

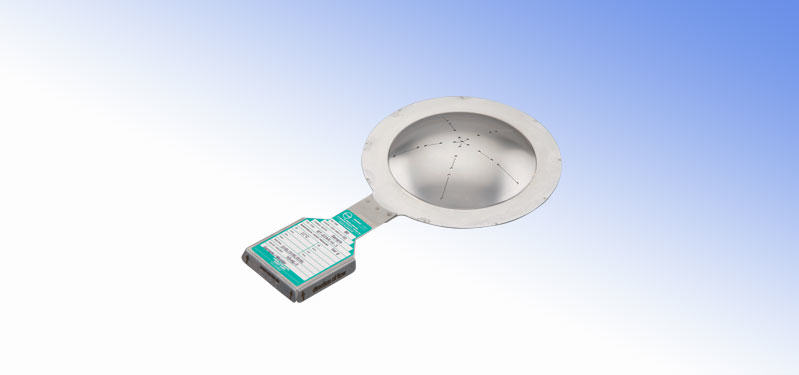

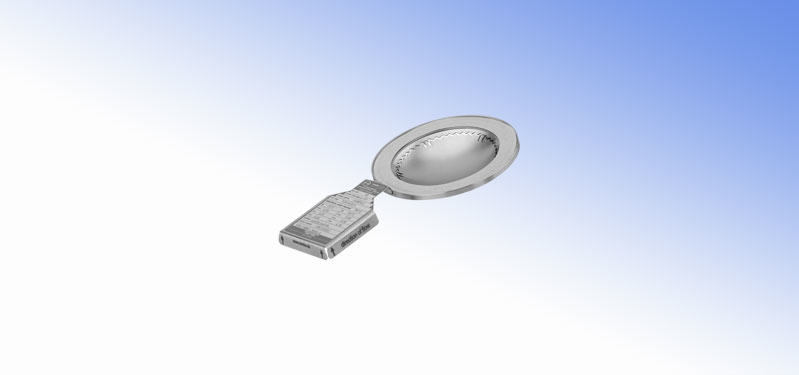

Three-layer safety plates are applied mostly for low, medium and high operating pressures. The solutions offered can operate at the level of 80% of the plate bursting pressure. Special bursting points (Bursting Discs), incised with a laser beam, ensure a high precision of the plate action and, in combination with a sealing membrane, determine the bursting pressure. Additionally, in case of very high bursting pressures, plates with a star-shaped incision are applied, which guarantees a lack of fragmentation after action.

To achieve the highest possible precision of action, the bursting points have been made with the use of the newest laser technology. The integrated strengthening guarantees resistance to action of vacuum, irrespective of the plate dimension.

In the case of the applications where corrosion may be a problem, the element that is subject to bursting is protected by means of a sealing membrane made in a standard way of FEP/PTFE. For high bursting pressure values, the membrane may also be made of stainless steel.

- Minimum bursting pressure: 0.015 bar(g)

- Dimension: 20-1400 mm

- Max. admissible operating pressure: up to 80% of bursting pressure

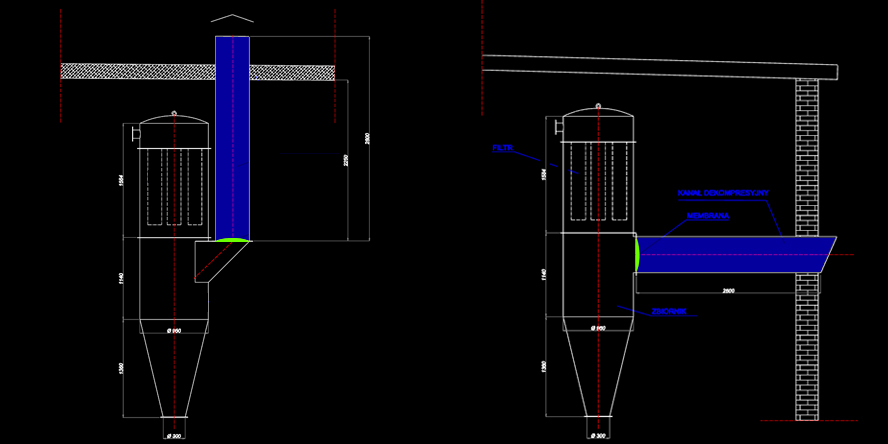

- Installation: between flanges in an integrated head and a tri-clamp type holder

- Construction: three-layer

- No fragmentation after action

- Long life span

- Suitable for pulsating pressure

- Liquid and gaseous media

- All industries where operation of the safety membrane with low, medium or high pressures is required

- Upstream safety valves as a protection

- Stainless steel

- Nickel

- Aluminium

- Inconel

- Monel

- Hastelloy

- Tantalus

- Titanium

- Teflon

- Making necessary calculations

- Delivery and installation