A fully functional 3D printer made of Lego block is his hallmark – Piotr Palczewski, a young engineer who graduated from AGH University of Science and Technology in Cracow proves that there is nothing impossible for brave and creative constructors.

His achievement had extensive media coverage – it was featured e.g. by: Gazeta Wyborcza, Rzeczpospolita and Focus. He was also to be heard of in numerous TV programmes.

Although the 3D printer is Piotr’s most publicised project, his ingenuity has been known since the beginning of his studies. For example, on the second year of his studies he created a fully functional… ticket machine. It will not be a surprise to anyone that this device was made of Lego blocks only, as well.

Piotr does not intend to rest on his laurels. His passion is to create new, innovative solutions that will have a tangible influence on people’s lives. Currently, under the auspices of WOLFF GROUP, he is embarking on another project to develop a new device. If the project succeeds, we will have a really powerful tool that could be used in numerous areas of life – comments Sebastian Gruszka, the marketing manager of WOLFF GROUP. What kind of product is it? You will learn that further in the article.

Sponsorship

Exceptional enthusiasm of the young constructor for creative use of his skills and also an unusual ability to combine the knowledge of the mechanics and programming field led to development of an intriguing idea in the head of Bartosz Wolff – the president of WOLFF GROUP. His first movement was to find Piotr and to have a short conversation with him. The aim of the meeting was to answer the crucial question – what is the true potential of Piotr Palczewski?

This could not wait. The meeting between Piotr Palczewski and Sebastian Gruszka was effected a few days later. During a short and casual conversation it turned out that the constructor intended to start work on a new and extremely fascinating project. There was only one problem. Piotr was not able to carry the financial burden of the new challenge.

The assumption of the project was to create a system to control devices with brain waves through a special helmet. In practice, it could be used for example by paralysed people to steer a wheelchair or to effectively type on a keyboard.

There was no time to spare. On 15 September, WOLFF GROUP formally initiated sponsorship of Piotr Palczewski. The letter of intent signed on that occasion postulated later commercialisation of the product. Controlling a device by means of thoughts is an amazing idea which may change the lives of thousands of people. We are very happy to support Piotr in this ambitious and very exciting undertaking – said Bartosz Wolff after the meeting.

Meeting in the WOLFF GROUP company – photo by WOLFF GROUP

About the project

Development of a system to control devices by means of brain waves is a very original project. In the first step, WOLFF GROUP will finance a purchase of a special EEG helmet which will collect and analyse signals coming from the brain (EEG waves).

The crucial phase of the project will be to develop a fully functional programme to converse EEG waves into speech with the use of a synthesizer. It will be possible to use the system to control a robot, a wheelchair and to allow paralysed people use a computer, not excluding typing. The works are scheduled to start in March 2016. We are eager to see the first results!

A project that fascinates

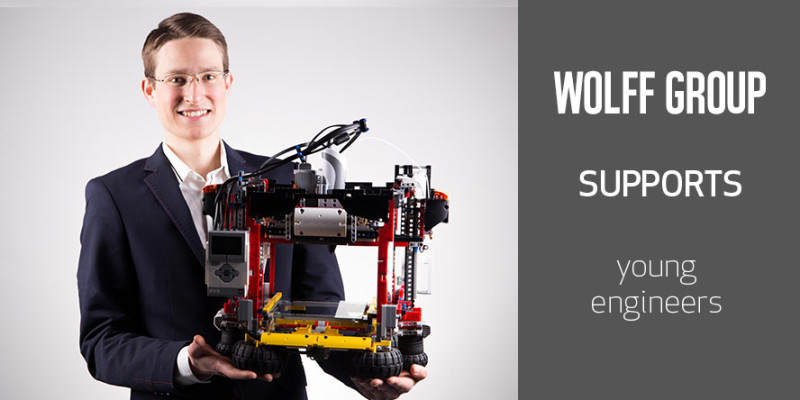

The passion to construct robotic devices and the love of Lego blocks led Piotr to create the unusual 3D printer built of Technic and Mindstorms Lego sets.

The device is composed of more than 1700 coloured parts, and the only elements that could not be replaced with blocks are the printhead and the filament, i.e. a special string out of which an object is printed.

The printer is about 35 cm high and 26 cm wide. Its value is estimated for about 3 thousand zloty by the author. How does the device work? The working area is a cuboid measuring 13 × 10 × 10 cm. The printing process is complex – the first stage involves modelling of the object that we want to receive (this may be prepared by any CAD software). Saved in SLT format, the model is copied to the programme, which divides it into separate layers and sends codes to the printer, on the basis of which the device will perform the programmed task. The printout is obtained with the 3D printing technology – ABS material in the form of a string located in the printhead is heated to the temperature of about 230°C. Melted string flows out of the printhead and by being distributed over the programmed trajectories, applying subsequent layers and solidifying, it constructs the desired, three-dimensional model.

Presentation of 3D printer – photo by WOLFF GROUP

WOLFF GROUP promotes bold technological solutions

This is not the first activity of WOLF GROUP to promote bold solutions of young engineers. Earlier, WOLFF GROUP had been an official sponsor of the Polish formula SAE (Society of Automotive Engineers), racing car developed at the University of Science and Technology in Cracow.

Being part of making innovative projects of young people come true is a source of great satisfaction for us.